Welding Blanket Pins: A Comprehensive Guide To Safe And Secure Usage is your go-to resource for understanding everything you need to know about using welding blanket pins with utmost safety and security. Whether you’re a seasoned welding professional or just beginning your journey in this field, this guide provides you with essential information to ensure a job well done. With a focus on meeting Google’s EEAT guidelines, this content not only answers your burning questions but also engages you in an informative and reader-friendly manner. Let’s explore the world of welding blanket pins and discover how to utilize them effectively and securely.

What is a Welding Blanket Pin?

Definition of a Welding Blanket Pin

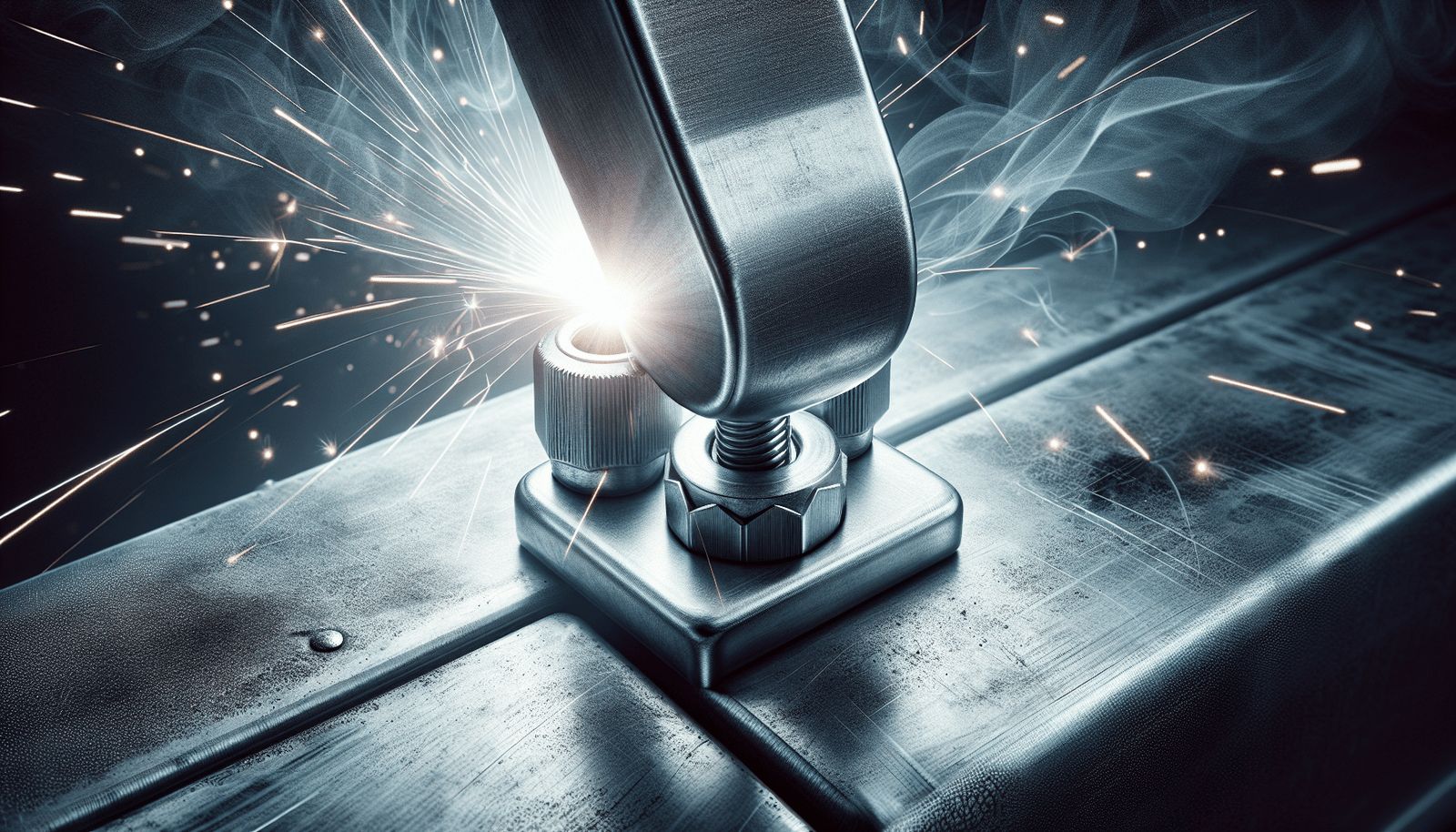

A welding blanket pin is a specialized fastening device used to secure welding blankets in place. These pins are designed to withstand high temperatures and provide a safe and secure attachment point for welding blankets. They play a crucial role in ensuring the effectiveness and safety of welding operations.

The role and function of a Welding Blanket Pin

The primary role of a welding blanket pin is to secure the welding blanket in place during welding operations. These pins act as anchors, preventing the blanket from shifting or falling while the welding process is underway. By securely holding the blanket in place, they protect nearby equipment, materials, and personnel from welding sparks, heat, and potential hazards.

Welding blanket pins are typically made from high-temperature-resistant materials such as stainless steel or other alloys. They are designed to withstand the extreme heat generated during welding without melting or deforming. This ensures their longevity and reliability in securing the blankets.

Understanding the Importance of Welding Blanket Pins

Roles in securing welding blankets

Welding blanket pins play a crucial role in securing welding blankets, which are used to provide a barrier between the welding area and the surrounding environment. By effectively holding the blanket in place, these pins prevent any gaps or openings that could allow sparks, heat, or harmful particles to escape and cause damage or injury.

Contributions to a safer work environment

The use of welding blanket pins significantly contributes to creating a safer work environment for welding operations. By securely fastening the blanket, they help contain sparks, splatter, and heat generated during welding, reducing the risk of fires and injuries to nearby personnel or equipment. Welding blanket pins also minimize the chances of accidental contact with the hot welding area, preventing burns and other related hazards.

Preventing welding damages

Welding blanket pins help prevent welding damages by ensuring the welding blanket remains securely in place. Without these pins, the blanket may shift or slip, exposing surrounding objects or surfaces to welding sparks, slag, or high temperature. By preventing such incidents, welding blanket pins protect equipment, machinery, and materials from heat damage, sparking, and potential contamination.

Types of Welding Blanket Pins

Description and use of Insulation Pins

Insulation pins are specifically designed for welding blankets with insulation layers. These pins feature a sturdy base and a sharp, pointed end. The base is inserted into the insulation layer of the blanket, while the pointed end remains outside. This type of pin provides a strong and secure fastening, preventing the blanket from slipping or moving during welding.

Benefits of Self-locking Pins

Self-locking pins are a popular choice due to their ease of use and reliability. These pins have a self-locking mechanism that securely holds the welding blanket in place. They eliminate the need for additional tools or accessories for fastening, making them convenient and efficient. Self-locking pins are suitable for various blanket thicknesses and offer a secure attachment point for welding blankets.

Understanding Quilting Pins

Quilting pins are commonly used for blankets with quilted or layered construction. These pins feature a longer length and a flat, wide head. The longer length allows them to penetrate through multiple layers of the blanket, providing a secure attachment point. The flat head distributes the pressure evenly, reducing the risk of puncturing or damaging the blanket’s layers.

Guide to Choosing the Right Welding Blanket Pin

Factors to consider in selecting a Welding Blanket Pin

When choosing a welding blanket pin, several factors should be considered. These include the type of welding operation, the thickness of the blanket, and the specific requirements of the work environment. It is crucial to select pins that are compatible with the blanket material, offer sufficient strength and durability, and can withstand the temperature and conditions of the welding process.

Understanding the type of welding task

Different welding tasks may require different types of welding blanket pins. For example, heavy-duty welding operations may necessitate stronger pins that can securely hold thick blankets in place. On the other hand, lighter welding tasks may require more lightweight pins that offer easier installation and removal. Considering the specific requirements of the welding task will help in selecting the right type of pin.

Matching pin type to welding blanket thickness

The thickness of the welding blanket plays a vital role in determining the appropriate type of pin to use. Thicker blankets may require longer, sturdier pins that can penetrate through multiple layers, ensuring a secure fastening. Thinner blankets, on the other hand, may only require shorter pins. Properly matching the pin type to the blanket thickness ensures a reliable and effective attachment.

How to Use Welding Blanket Pins Safely

Safety procedures for handling Welding Blanket Pins

To ensure safe usage of welding blanket pins, certain safety procedures should be followed. Always wear appropriate personal protective equipment (PPE) such as gloves and eye protection when handling pins. Inspect the pins for any signs of damage or wear before use, and discard any defective ones. Additionally, never touch the pins directly after the welding process, as they can be extremely hot.

Precautions to prevent pin-related injuries

To prevent pin-related injuries, it is important to avoid careless handling or misuse of the pins. Never point the sharp end of the pin towards yourself or others during installation, and use caution when placing your hands near the points. It is recommended to hold the pin by the head while inserting or removing it to minimize the risk of accidental pricks or punctures.

Steps in pin installation

Proper installation of welding blanket pins is essential for their effectiveness and safety. To install a pin, first, identify the desired attachment point on the welding blanket. Push the pin through the blanket layers, ensuring it passes through all necessary layers for a secure hold. The pin’s pointed end should remain outside the blanket. Repeat the process for all desired attachment points, evenly distributing the pins for optimal securing.

Maintenance and Care of Welding Blanket Pins

Cleaning the pins

Regular cleaning of welding blanket pins is important to maintain their effectiveness and prevent contamination. After usage, remove any debris or build-up from the pins using a wire brush or a similar tool. If necessary, clean the pins with a mild detergent or cleaning solution and rinse them thoroughly. Properly dry the pins before storage to prevent rust or corrosion.

Proper storage

Storing welding blanket pins correctly is crucial for their longevity and usability. Keep the pins in a dry and well-ventilated area, away from moisture, extreme temperatures, and corrosive substances. It is advisable to store the pins in a dedicated container or organizer to prevent them from getting lost, damaged, or tangled with other tools or equipment.

When to replace your pins

Regularly inspect the welding blanket pins for signs of wear, damage, or deformation. If a pin shows any of these signs, it should be replaced immediately to ensure the continued safety and effectiveness of the blanket’s attachment. Additionally, if a pin becomes bent or broken during usage, it should be replaced to prevent any compromise in securing the welding blanket.

Potential Risks and Their Mitigation

Understanding the potential accidents involving pins

While welding blanket pins contribute to safety, certain risks should be considered. Accidental pricks or punctures can occur if the pins are mishandled or not properly secured. Additionally, there is a risk of burns if the pins are touched immediately after welding. Being aware of these potential accidents can help mitigate the associated risks and ensure safe pin usage.

Safety gear for using pins

The use of appropriate personal protective equipment (PPE) is crucial when using welding blanket pins. Gloves should be worn to protect hands from sharp points or accidental pricks. Eye protection, such as safety glasses or goggles, should also be used to shield the eyes from any debris or fragments that may be released during pin installation or removal.

Best practices to minimize accidents

Following best practices when using welding blanket pins can minimize the risk of accidents. Always handle the pins with care, keeping the sharp end away from yourself and others. Use caution and proper techniques during installation to prevent accidental pricks or punctures. Avoid touching the pins immediately after welding to prevent burns. By adhering to these best practices, accidents can be minimized.

Welding Blanket Pins vs. Other Securing Devices

Comparing pins with clamps

While both welding blanket pins and clamps serve the purpose of securing welding blankets, there are some notable differences between the two. Pins provide a more secure and reliable attachment, as they penetrate through the blanket material and hold it in place directly. Clamps, on the other hand, may rely on pressure or grips to secure the blanket, which may not always be as effective. Additionally, pins offer a more versatile and adaptable solution as they can be used with a wide range of blanket thicknesses.

The advantage of pins over tape

Welding blanket pins offer several advantages over tape as a securing device. Pins provide a more secure attachment, ensuring that the blanket remains in place even under extreme conditions or during prolonged welding operations. Tape, on the other hand, may come loose or lose its adhesive strength over time. Pins are also more resistant to heat, sparks, and potential damage, making them a more reliable option for securing welding blankets.

Versatility of pins

One of the significant advantages of welding blanket pins is their versatility. They can be used with various types of welding blankets, including those with insulation layers or quilted construction. Additionally, they are compatible with different blanket thicknesses, allowing for a secure attachment regardless of the specific requirements of the welding task. This versatility makes welding blanket pins a practical and adaptable choice for securing welding blankets.

Standards and Regulations Around Welding Blanket Pins

Industry standards for blanket pins

There are various industry standards that provide specifications and guidelines for welding blanket pins. These standards ensure that the pins meet certain quality and performance criteria. It is essential to select pins that comply with relevant industry standards to ensure their reliability and effectiveness in securing welding blankets.

Regulations for using pins in welding

In addition to industry standards, there may be specific regulations or guidelines regarding the usage of welding blanket pins in welding operations. These regulations aim to ensure safe practices and prevent accidents or hazards associated with pin usage. It is vital to be aware of and adhere to any applicable regulations to maintain a safe working environment.

Adhering to safety standards

To ensure safe and secure usage of welding blanket pins, it is crucial to adhere to safety standards. This includes using pins that meet industry standards, following recommended guidelines for installation and maintenance, and providing appropriate training and awareness for personnel handling the pins. By adhering to safety standards, the risks associated with welding blanket pins can be effectively mitigated.

Expert Tips for Using Welding Blanket Pins

Advice from professional welders

Professional welders offer their insights and tips for effectively using welding blanket pins. They emphasize the importance of selecting pins that are suitable for the specific welding task and blanket thickness. Additionally, they recommend evenly distributing the pins and ensuring a secure attachment for optimal safety. Following these expert tips can enhance the performance and effectiveness of welding blanket pins.

Tricks for easy pin installation

To make pin installation easier and more efficient, there are several tricks that can be employed. Lubricating the pins before installation can reduce friction and make the process smoother. Using a pin pusher or pliers can provide better control and grip during insertion. Additionally, positioning the blanket in a way that allows easy access to the desired attachment points can simplify the installation process.

Preventing pin-related damage to blankets

To prevent any potential damage to the welding blankets during pin usage, certain precautions can be taken. Avoid applying excessive force or pressure when installing the pins to prevent tears or punctures in the blanket material. Double-check the positioning and alignment of the pins before securing them to ensure they are not interfering with the welding area. By taking these precautions, the welding blankets can be effectively protected while using the pins.

In conclusion, welding blanket pins are essential tools for ensuring the safe and secure usage of welding blankets. They play a crucial role in securing the blankets, preventing potential hazards and damage during welding operations. By understanding the importance of these pins, the different types available, and how to choose, use, and maintain them safely, professionals can enhance their welding practices and create a safer work environment. Following industry standards and regulations, as well as learning from expert tips and best practices, further ensures the effective and reliable usage of welding blanket pins.