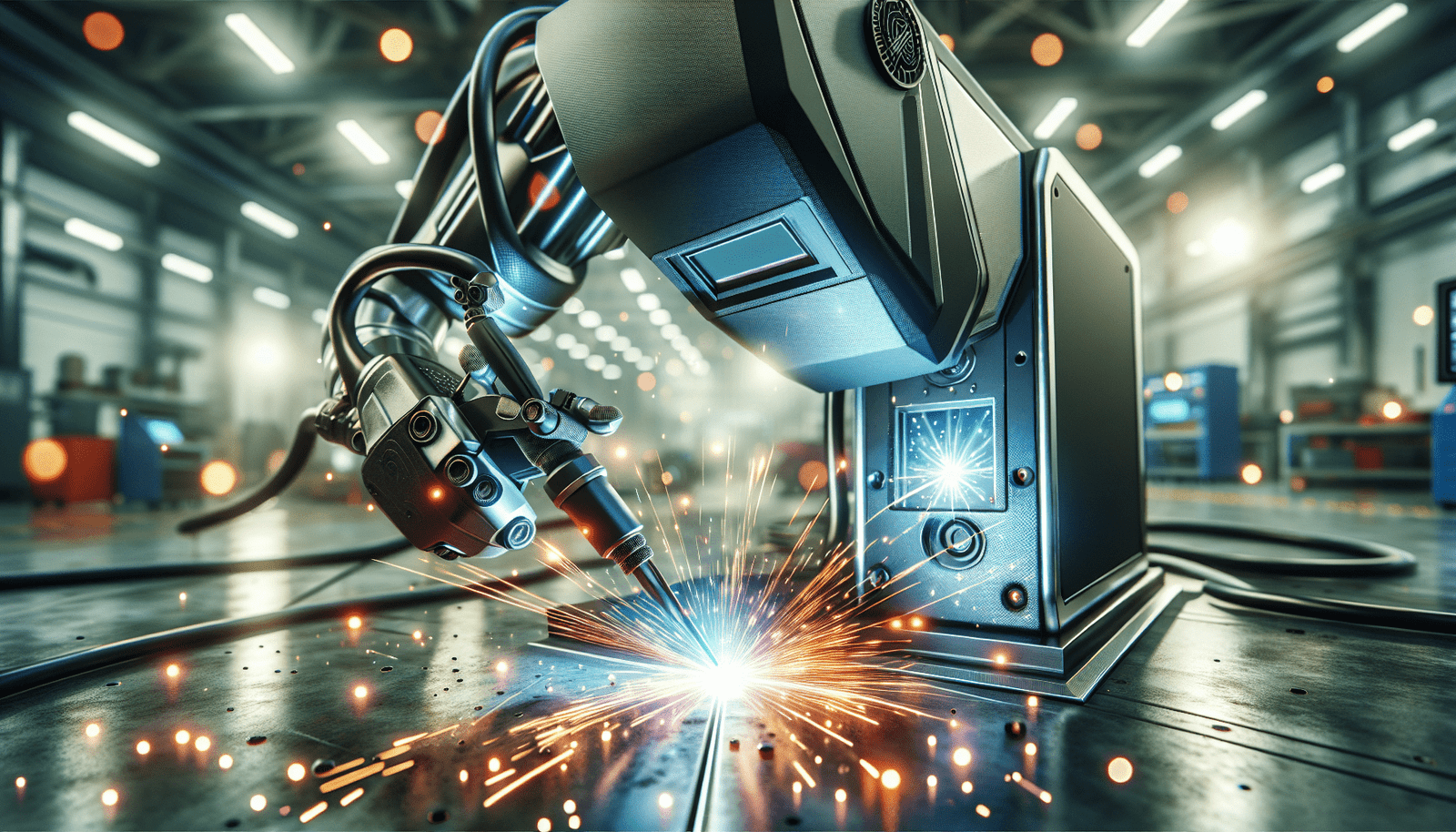

If you’re in the market for a top-notch TIG welding machine designed specifically for industrial use, then this article is just for you. In this comprehensive guide, we’ll take a close look at the top 5 TIG welding machines that will meet and exceed your expectations. Whether you’re a welding professional or simply interested in investing in a high-quality welding tool, we’ve got you covered. From their features and capabilities to their durability and performance, we’ll provide you with all the information you need to make an informed decision. So, let’s dive right in and discover the best TIG welding machines that the market has to offer!

Understanding TIG Welding

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a popular welding technique that uses a non-consumable tungsten electrode to create a weld. The electrode heats the metal alloys and fills the joint with molten metal, creating a strong and precise weld. This welding process requires a high level of skill and control, making it a preferred choice for industries that demand precision and quality in their welding projects.

The working principle of TIG welding

TIG welding works by creating an electric arc between the tungsten electrode and the workpiece. This arc produces an intense heat that melts the metal alloys, causing them to bond together. To protect the welding area from contaminants, an inert gas, usually argon or helium, is used. The inert gas flows through the welding torch, shielding the molten metal and preventing oxidation. This ensures a clean and strong weld.

The role of TIG welding in industries

TIG welding is highly valued in industries that require precise and high-quality welds. It is commonly used in the aerospace, automotive, and manufacturing industries, where precision and strength are paramount. TIG welding is especially suitable for welding thin materials, such as aluminum, stainless steel, and copper alloys. The ability to control the heat input and the versatility of TIG welding make it invaluable in industries where precision welding is crucial.

Importance of selecting the right TIG welding machine

Choosing the right TIG welding machine is essential to ensure the success of your welding projects. Factors such as the machine’s amperage range, AC/DC options, ease of use and portability, heat control functionalities, and the material of the workpiece should be considered. Investing in a high-quality TIG welding machine not only improves the efficiency of your welding projects but also enhances the overall weld quality and reduces the risk of welding defects.

Factors to Consider When Choosing a TIG Welding Machine

When selecting a TIG welding machine, it is crucial to consider several factors to ensure the machine meets your specific welding needs. Here are some factors to consider when choosing a TIG welding machine:

Machine’s amperage range

The machine’s amperage range determines its welding capabilities. Consider the types and thicknesses of materials you will be welding, and choose a TIG welding machine that offers a suitable amperage range. It is essential to select a machine that can handle both thin and thick materials to ensure versatility in your welding projects.

AC/DC options

TIG welding machines with AC/DC options provide greater flexibility in welding different materials. If you plan to work with both aluminum and steel, choose a machine that offers AC/DC capabilities. This will allow you to weld a wide range of materials without the need for additional equipment.

Ease of use and portability

For beginners or welders who frequently move from one location to another, ease of use and portability are crucial factors to consider. Look for a TIG welding machine that is user-friendly, with intuitive controls and a clear interface. Consider the weight and size of the machine if you need to transport it frequently.

Heat control functionalities

Precise heat control is essential in TIG welding, especially when working with delicate materials. Look for a TIG welding machine that offers adjustable heat control functionalities, such as pulse welding, slope-up/down, and pre/post-flow options. These features allow you to fine-tune the heat input and achieve consistent and high-quality welds.

The material of the workpiece

Consider the types of materials you will be welding and choose a TIG welding machine that is suitable for those materials. Different materials require different welding parameters and techniques. Ensure that the machine you choose can handle the specific material you will be working with.

Miller Electric Maxstar 161 STL Series TIG Welder

The Miller Electric Maxstar 161 STL Series TIG Welder is a high-quality TIG welding machine known for its exceptional performance and durability. Here are its overview and standout features:

Overview and standout features

The Miller Electric Maxstar 161 STL Series TIG Welder is a compact and lightweight machine, making it highly portable and suitable for various welding applications. It offers a wide amperage range of 5A to 160A, allowing for both thin and thick material welding. The machine features DC output and high-frequency arc starts, ensuring smooth and stable arc initiation. The advanced power source technology of the Maxstar 161 STL provides excellent arc control and minimizes welding defects.

Why it’s ideal for industrial use

The Miller Electric Maxstar 161 STL Series TIG Welder is widely used in industrial settings due to its versatility, ease of use, and high-quality welds. Its compact size and lightweight design make it ideal for welding projects that require mobility. The machine’s exceptional arc control and precise heat input make it suitable for welding various materials, including stainless steel and aluminum. It is backed by Miller Electric’s reputation for manufacturing reliable and durable welding equipment, ensuring its reliability in demanding industrial environments.

Customer reviews and ratings

Customers rave about the Miller Electric Maxstar 161 STL Series TIG Welder’s performance and reliability. Many reviewers appreciate its portability and ease of use, making it an excellent choice for both professionals and beginners. The machine’s precise arc control and stable arc initiation receive high praise from welders who require consistent and high-quality welds. Overall, the customer reviews and ratings for the Maxstar 161 STL are overwhelmingly positive.

Price comparison and where to buy

The price of the Miller Electric Maxstar 161 STL Series TIG Welder varies depending on the retailer and any additional accessories included. To ensure the best price and availability, it is recommended to check with authorized welding equipment distributors or reputable online retailers.

Overview of manufacturer (Miller Electric)

Miller Electric is a renowned manufacturer of welding equipment and is well-known for producing high-quality and innovative machines. With a history spanning over 90 years, Miller Electric has earned a reputation for manufacturing reliable and durable welding machines that meet the demands of various industries. Their commitment to excellence and customer satisfaction makes them a trusted brand for welders worldwide.

(Continued in the next section)