So, you’ve decided to take up welding as a new hobby or perhaps even as a potential career path. That’s fantastic! But where do you even begin when it comes to acquiring the necessary tools for your new endeavor? Well, fear not, because in this article, we will be diving into the top 10 must-have welding tools for beginners. Whether you’re just starting out or looking to expand your collection, these tools are essential for any aspiring welder. So, let’s jump right in and discover the key equipment you need to kick-start your welding journey!

Safety Gear

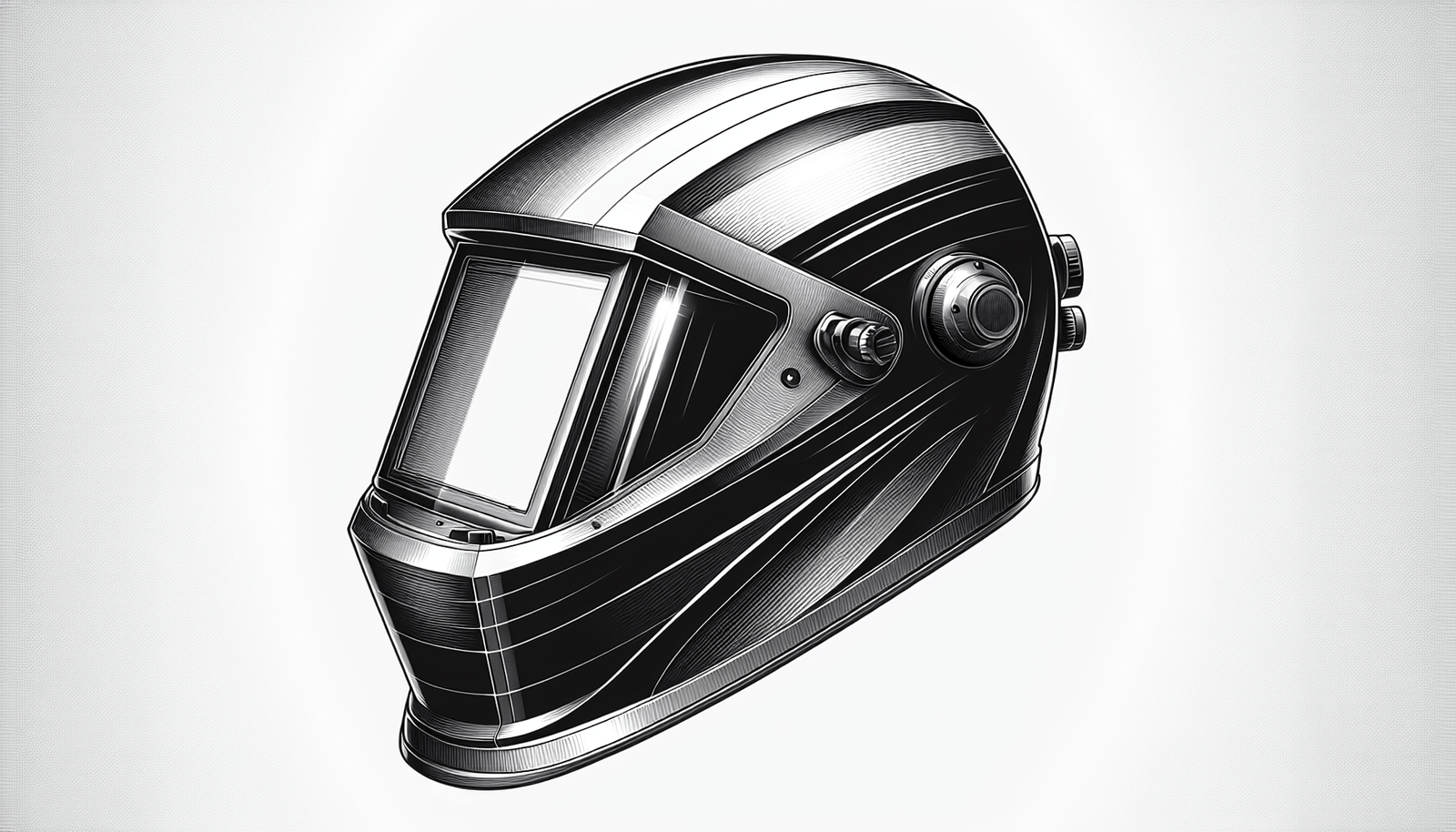

Welding Helmet: Shield your eyes and face

A welding helmet is an essential piece of safety gear that all welders should have. It protects your eyes and face from the intense light, sparks, and debris that can be generated during welding. The helmet is designed to automatically darken when the welding arc is struck, providing you with optimal visibility while still keeping your eyes safe. Look for a helmet with a wide viewing area and adjustable settings to ensure comfort and convenience while working.

Welding Gloves: Protect your hands

Welding gloves are specially designed to withstand the heat and sparks generated during welding. They provide protection for your hands against burns, cuts, and abrasions. Look for gloves made from high-quality materials like leather or Kevlar that can withstand high temperatures and offer good dexterity. It’s important to choose gloves that fit properly to ensure maximum protection and flexibility while working.

Safety Glasses: Extra layer of eye protection

In addition to a welding helmet, safety glasses provide an extra layer of protection for your eyes. They protect against flying debris, sparks, and harmful UV rays. Look for safety glasses that are impact-resistant and have built-in side shields for added protection. It’s also important to choose glasses that fit comfortably and securely to prevent them from slipping or falling off during work.

Respirator: Breathing safety

Welding produces hazardous fumes and gases that can be harmful if inhaled. A respirator is necessary to protect your lungs from these toxic substances. Look for a respirator that is specifically designed for welding applications and provides a high level of filtration. It should have adjustable straps for a secure and comfortable fit. Make sure to follow the manufacturer’s instructions on how to properly wear and maintain the respirator.

Welding Jacket: Shield your body from sparks

A welding jacket is an essential piece of protective clothing that shields your body from sparks, spatter, and heat. It should be made from flame-resistant materials like leather or heavy-duty cotton. Look for a jacket that fits properly and provides full coverage to ensure maximum protection. It should also have features like adjustable cuffs and a stand-up collar to provide a comfortable and secure fit.

Welding Machines

MIG Welder: For beginners and general repairs

A MIG (Metal Inert Gas) welder is an excellent choice for beginners and for general welding repairs. It is easy to use and allows for fast and efficient welding. The MIG process uses a wire electrode that is automatically fed through the welding gun, along with a shielding gas, to create a strong weld. Look for a MIG welder that offers multiple voltage settings and wire feed speed control for versatility in different welding applications.

TIG Welder: For precise, clean welds

A TIG (Tungsten Inert Gas) welder is ideal for producing precise and clean welds. It is commonly used for welding thin materials like stainless steel and aluminum. The TIG process uses a non-consumable tungsten electrode and a separate filler rod, which gives the welder greater control over the heat and weld puddle. Look for a TIG welder with variable amperage control and a foot pedal for ease of operation.

Stick Welder: For heavy-duty, outdoor projects

A stick welder, also known as an arc welder or shielded metal arc welder (SMAW), is a versatile and reliable welding machine. It is suitable for heavy-duty welding tasks and can be used both indoors and outdoors. The stick welding process uses a consumable electrode coated in flux, which creates a shielded arc to weld the metal. Look for a stick welder with adjustable amperage settings and a duty cycle suitable for your intended projects.

Cutting Tools

Oxy-acetylene Torch: For cutting, welding, and heating

An oxy-acetylene torch is a versatile cutting tool that can also be used for welding and heating. It uses a mixture of oxygen and acetylene gas to create a high-temperature flame for cutting through various metals. Look for a torch kit that includes appropriate tips for cutting, welding, and heating, as well as a suitable fuel gas cylinder and proper safety equipment.

Plasma Cutter: For cutting thick material

A plasma cutter is a cutting tool that uses a high-velocity jet of ionized gas to melt and pierce through metal. It is ideal for cutting thick materials, such as steel and aluminum, with precision and speed. Look for a plasma cutter that offers high amperage output and precise control over the cutting arc. Consider the duty cycle and cutting capacity to ensure it meets your specific needs.

Hand Tools

Chipping Hammer: For removing slag

A chipping hammer is a handheld tool used to remove slag, the residue left behind after welding. It has a pointed end for chipping away the slag and a flat end for cleaning the welding surface. Look for a chipping hammer with a comfortable grip and durable construction that can withstand the repetitive impact.

Wire Brush: For cleaning the welding surface

A wire brush is an essential tool for cleaning the welding surface before and after welding. It removes rust, paint, and other contaminants that can affect the quality of the weld. Look for a wire brush with stiff, durable bristles that can effectively remove debris without damaging the metal surface.

MIG Pliers: A versatile tool for various tasks

MIG pliers are a versatile tool that can be used for multiple tasks in the welding process. They are designed to trim, grip, and remove welding wire, as well as clean the welding nozzle. Look for MIG pliers with comfortable handles and various functions like wire cutting, nozzle cleaning, and tip removal.

Measurement and Marking Tools

Tape Measure: For accurate measurements

A tape measure is an essential tool for accurate measurements in welding projects. It helps ensure precise cuts and proper alignment of materials. Look for a tape measure with a sturdy construction and clear markings for easy reading. Consider the length and width of the tape to suit your specific needs.

Square: For square and angle measurements

A square is a tool used to measure and mark square and angle measurements in welding projects. It helps ensure accurate and precise cuts and welds. Look for a square with a durable construction, clear markings, and an adjustable angle feature for versatility in different applications.

Scriber: For marking your cuts and welds

A scriber is a tool used to mark cuts, welds, and measurements on metal surfaces. It creates fine lines that serve as guides during the welding process. Look for a scriber with a sharp and durable tip, as well as a comfortable handle for ease of use.

Power Tools

Angle Grinder: For polishing and cutting

An angle grinder is a versatile power tool that can be used for polishing, cutting, and grinding metal. It is especially useful for preparing metal surfaces before welding and for shaping and smoothing welds after they are completed. Look for an angle grinder with a powerful motor, adjustable speed settings, and a variety of grinding discs and cutting wheels.

Drill: For various drilling needs

A drill is an essential power tool for various drilling needs in welding projects. It can be used to create holes, install fasteners, and perform other tasks. Look for a drill with adjustable speed settings and a chuck size that can accommodate the drill bits you will be using. Consider the power source (corded or cordless) based on your specific requirements.

Clamps and Holders

Locking Clamps: For holding your workpiece securely

Locking clamps are essential for holding your workpiece securely in place during welding. They provide stability and help maintain proper alignment. Look for locking clamps with strong and durable construction, adjustable pressure, and a comfortable handle for ease of use.

Magnetic Holders: For holding your workpiece at various angles

Magnetic holders are useful for holding your workpiece at various angles during welding. They provide a strong, secure hold without the need for clamps or other fasteners. Look for magnetic holders with high magnetic strength and a swivel feature for versatile positioning.

Welding Table or Cart

Welding Table: A flat, heat-resistant surface to work on

A welding table provides a flat, heat-resistant surface to work on during welding projects. It allows for easy manipulation and positioning of the workpiece. Look for a welding table with a sturdy construction, adjustable height, and a heat-resistant tabletop. Consider additional features like built-in clamps or slots for holding tools.

Welding Cart: For storing and transporting your equipment

A welding cart is a convenient tool for storing and transporting your welding equipment. It keeps everything organized and easily accessible, allowing you to move your equipment around the workshop or job site with ease. Look for a welding cart with sturdy construction, ample storage space, and wheels for easy maneuverability.

Welding Wire and Electrodes

Welding Wire: For MIG and flux-cored welding

Welding wire is a consumable filler metal used in MIG and flux-cored welding processes. It is available in various sizes and types to suit different materials and welding applications. Look for welding wire that is compatible with your specific welding machine and the type of metal you will be welding.

Electrodes: For stick welding

Electrodes are a consumable filler material used in stick welding. They provide the metal that melts and fuses together to create the weld. Electrodes are available in different sizes and types for various welding applications and metal types. Look for electrodes that are suitable for your specific welding machine and project requirements.

Cleaning and Maintenance Supplies

Nozzle Gel: Keeps your equipment in good shape

Nozzle gel is a cleaning and cooling agent that helps prevent spatter buildup on the welding nozzle. It extends the life of the nozzle and ensures consistent gas flow during welding. Look for nozzle gel that is specifically designed for your welding machine and follow the manufacturer’s instructions for proper use and maintenance.

Anti-spatter Spray: Protects your workpiece from spatter

Anti-spatter spray is a coating that helps prevent spatter from sticking to your workpiece during welding. It creates a protective barrier that can easily be removed after welding. Look for anti-spatter spray that is suitable for your specific welding process and materials.

Grinding Discs: For shaping, smoothing, and polishing your welds

Grinding discs are essential for shaping, smoothing, and polishing your welds. They are available in various grit sizes for different levels of material removal and finishing. Look for grinding discs that are compatible with your angle grinder and suitable for your specific welding applications. Consider the material and thickness of the discs for durability and performance.