When it comes to using welding face shields, safety should always be a top priority. Protecting your eyes and face from sparks, debris, and harmful radiation is essential for a successful and injury-free welding experience. In this article, we will provide you with a concise yet comprehensive guide to using welding face shields safely. From the importance of proper fit and maintenance to understanding the different types of face shields available, we’ve got you covered. So, let’s dive in and ensure your welding journey is both productive and protected!

Understanding the Importance of Welding Face Shields

Explaining the role of face shields in welding

When it comes to welding, safety should always be the top priority. One of the essential safety measures in welding is the use of face shields. These protective gear items play a crucial role in shielding your face and eyes from the various hazards associated with welding.

During the welding process, there are several dangers that can pose a threat to your vision and overall safety. These hazards include sparks, flying debris, intense light, and harmful UV radiation. A welding face shield acts as a barrier, preventing these hazards from reaching your face and eyes.

Dangers of not using face shields during welding

Choosing not to use a welding face shield can have severe consequences for your health and safety. Without proper protection, you expose yourself to the risk of eye injuries, burns, and long-term damage to your vision. The intense light produced during welding can cause arc eye, a painful condition that feels like having sand in your eyes. Prolonged exposure to UV radiation can lead to cataracts and other vision problems.

In addition to eye-related risks, not using a face shield also puts you at risk of burns from sparks and flying debris. These can cause painful injuries on your face and skin, which can require medical attention and result in scarring. Protecting yourself with a well-designed welding face shield is essential to prevent these potential dangers.

Beneficial features of welding face shields

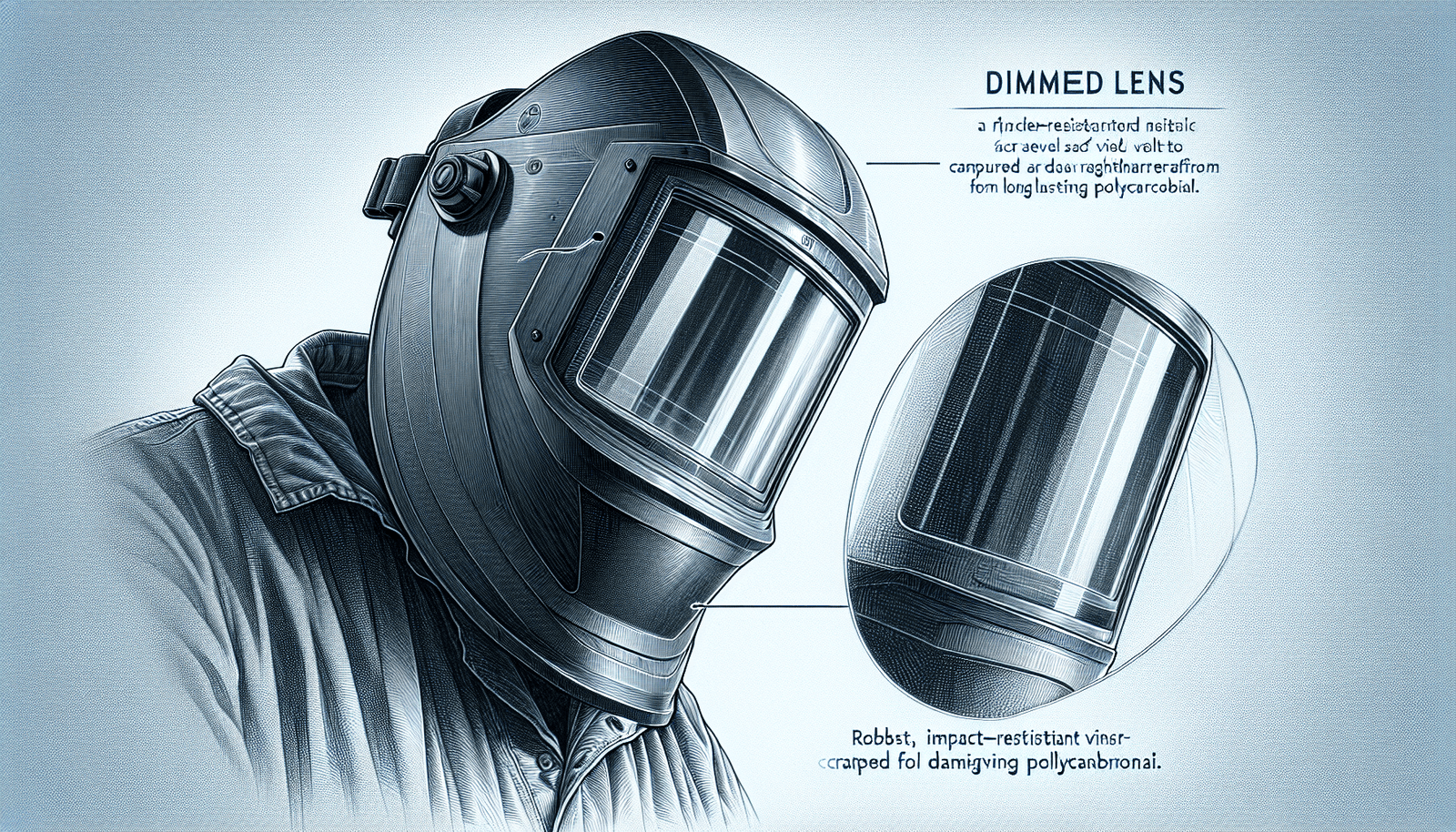

Welding face shields come with several beneficial features that enhance safety and comfort during the welding process. Firstly, they are equipped with a strong, impact-resistant visor that shields your face and eyes from sparks and debris. This visor is usually made of durable materials like polycarbonate, which offers high optical clarity and resistance to impact.

Many welding face shields also feature a tinted lens to protect your eyes from the intense light and harmful UV radiation produced during welding. The tint reduces glare and ensures that the light is filtered properly, preventing any damage to your vision.

Some welding face shields also come with a flip-up or flip-down option, allowing you to easily switch between protected and unprotected views. This is particularly useful when you need to inspect your work or communicate with others without removing the shield completely.

Choosing a Proper Face Shield When it comes to selecting a welding face shield, there are several factors to consider to ensure maximum protection and comfort.

Factors to consider when buying a welding face shield

The first factor to consider is the level of protection provided by the face shield. Look for shields that comply with international safety standards, as they undergo rigorous testing to ensure their effectiveness against the hazards of welding. Check for certifications and markings that indicate compliance with industry standards.

Another crucial factor to consider is the fit and comfort of the face shield. It should fit securely and comfortably on your head, allowing for proper coverage and unrestricted movement. Adjustable straps and cushioning materials can help achieve an optimal fit.

Additionally, the weight of the face shield also plays a role in your comfort. Look for lightweight options that won’t cause strain or discomfort during long welding sessions. It’s also worth considering the ease of maintenance and cleaning, as you’ll want a face shield that is easy to keep in good condition.

Examining different types of welding face shields

There are several types of welding face shields available, each designed to suit different welding applications and personal preferences.

One common type is the passive welding face shield, which features a fixed tinted lens. This type provides constant protection against intense light and UV radiation. However, some welders may find the fixed tint too dark for certain tasks and prefer a shield with an adjustable lens.

For those looking for versatility, auto-darkening welding face shields are a great option. These shields feature a lens that automatically adjusts its tint based on the intensity of the light. This ensures optimal visibility during welding and eliminates the need for constantly flipping the shield up and down.

The role of comfort and fit in selecting a face shield

Comfort and fit should be significant considerations when selecting a welding face shield. A poorly fitting face shield can be uncomfortable to wear and may not provide full coverage and protection. Look for face shields with adjustable straps and cushioning materials for a secure and comfortable fit.

A face shield that fits properly should cover your entire face, extending from your forehead to below your chin. It should sit snugly against your face, with no gaps that could allow hazards to enter. The shield should also be positioned at a suitable distance from your eyes, allowing for clear vision and unrestricted movement.

Evaluating the comfort and fit of a face shield before purchasing is essential, as it will be your primary protective gear during welding operations.

Proper Use of Welding Face Shields

How to wear a welding face shield correctly

Wearing a welding face shield correctly is crucial to ensure maximum protection during welding activities. Here’s a step-by-step guide on how to wear a welding face shield properly:

Start by adjusting the straps on the face shield to ensure a secure and comfortable fit. Tighten or loosen the straps as needed to achieve the desired fit.

Place the face shield over your head, ensuring that it covers your entire face from forehead to below your chin.

Make sure the shield is positioned at a comfortable distance from your eyes, allowing for clear and unobstructed vision.

Secure the straps, ensuring that the face shield remains in place throughout the welding process.

Adjusting the face shield for secure fit

In addition to wearing the face shield correctly, it’s important to adjust it properly for a secure fit. Improper adjustment can compromise the effectiveness of the shield and leave you vulnerable to hazards. Here are some tips for adjusting your welding face shield:

Check that the shield sits snugly against your face, with no gaps. If you notice any gaps, readjust the straps or cushioning materials to ensure a close fit.

Pay attention to the position of the shield. It should be at a suitable distance from your eyes, allowing for clear vision without obstructing your view.

Ensure that the straps are tightened enough to prevent the face shield from moving or falling off during welding. However, be mindful not to overtighten, as it can cause discomfort and pressure points.

Understanding the limitations of a welding face shield

While welding face shields provide significant protection, it’s important to understand their limitations. They are designed to shield your face and eyes from sparks, flying debris, intense light, and UV radiation. However, they do not provide complete protection from all welding hazards.

For example, welding face shields do not provide respiratory protection. If you are working in an environment with fumes, gases, or other airborne hazards, it is essential to use appropriate respiratory protective equipment in addition to your welding face shield.

Welding face shields also have limitations in terms of impact resistance. While they can protect you from most flying debris, they may not withstand heavy or high-velocity objects. If you anticipate working in areas with a higher risk of impact, it may be necessary to consider additional protective measures, such as a helmet or a more robust face shield.

Maintenance and Care of Welding Face Shields

Routine inspection of welding face shields for damage

Regular inspection of your welding face shields is essential to ensure their effectiveness and detect any damage that may compromise their protective capabilities. Here’s a step-by-step guide on how to inspect your face shield for damage:

Before each use, visually inspect the face shield for any cracks, dents, or signs of wear and tear. Pay particular attention to the area around the visor, straps, and cushioning materials.

Check the lens for any scratches or damage that may obstruct your vision. Scratched lenses should be replaced promptly to maintain clear visibility.

Inspect the straps for any signs of fraying or stretching. Replace any damaged straps to ensure a secure fit.

If your face shield has any adjustable parts, such as flip-up lenses or ventilation openings, ensure they are functioning correctly and securely.

Cleaning and storing welding face shields

Proper cleaning and storage of your welding face shield help maintain its clarity, effectiveness, and lifespan. Here are some guidelines for cleaning and storing your welding face shield:

After each use, remove any debris or dust from the face shield using a soft cloth or brush. Be gentle to avoid scratching the visor.

Use a mild soap or cleaning solution to clean the visor. Avoid using abrasive cleaners, as they can damage the lens.

Rinse the visor thoroughly with clean water to remove any soapy residue.

Allow the face shield to air dry completely before storing it. Avoid exposing the shield to direct sunlight or high heat, as it can damage the materials.

Store the face shield in a clean, dry, and dust-free area. Ideally, keep it in a protective bag or case to prevent scratches and damage.

Replacing parts of the face shield as needed

Over time, certain parts of your welding face shield may wear out or become damaged. It’s important to replace these parts promptly to ensure the continued effectiveness of your face shield. Here are some parts that may need replacement:

Visor: If the visor becomes cracked or deeply scratched, it should be replaced. A damaged visor can obstruct your vision and compromise the face shield’s ability to protect your face and eyes.

Straps: If the straps become frayed or stretched, they may no longer provide a secure fit. Replace any damaged straps to ensure the face shield stays in place during welding.

Cushioning materials: If the cushioning materials become worn out or lose their shape, they may not provide optimal comfort or a secure fit. Replace any worn or damaged cushioning materials to ensure the face shield remains comfortable to wear.

Keep a close eye on the condition of your welding face shield and replace any damaged or worn parts promptly to maintain its effectiveness and your safety.

Dealing with Fogging and Overheating

Why fogging occurs and how it can be prevented

Fogging of welding face shields can be a common issue, especially when working in humid environments or during intense welding activities. Fogging occurs due to the temperature difference between the inside and outside of the face shield, causing condensation to form on the inner surface of the visor.

To prevent fogging, consider the following tips:

Anti-fog coating: Some welding face shields come with an anti-fog coating on the inside of the visor. This coating helps prevent condensation by reducing the surface tension of water droplets, allowing them to disperse evenly.

Ventilation: Look for face shields with integrated ventilation systems or openings that allow air to circulate inside the shield. Proper ventilation can help reduce fogging by equalizing the temperature and humidity inside the face shield with the surrounding environment.

Use a defogging solution: Apply a commercial defogging solution or a mixture of water and baby shampoo to the inside of the visor. This creates a thin film that can prevent condensation from forming.

Avoid excessive breathing towards the shield: When exhaling, try to direct your breath away from the face shield to minimize the amount of warm, moist air that comes into contact with the visor.

By implementing these strategies, you can significantly reduce the occurrence of fogging and maintain clear visibility during welding.

Managing overheating when wearing a face shield

Wearing a welding face shield can sometimes lead to discomfort and overheating, especially in hot and humid conditions. Managing overheating is crucial to ensure your safety and comfort during welding. Consider these tips to prevent overheating:

Choose a face shield with proper ventilation: Look for face shields with integrated ventilation systems or openings that allow air to circulate freely. This helps dissipate heat and prevent excessive sweating.

Take scheduled breaks: Regular breaks during welding allow your body to cool down and regulate temperature. Schedule breaks to remove the face shield and take a few minutes to rest and cool off.

Stay hydrated: Drink plenty of water before, during, and after welding to stay hydrated. Proper hydration can help regulate your body temperature and prevent overheating.

Use lightweight and breathable clothing: Opt for lightweight, breathable clothing that allows air to circulate and wicks away moisture. This helps prevent excessive sweating and discomfort.

Options for ventilation and cooling in welding face shields

To enhance ventilation and cooling while wearing a welding face shield, consider the following options:

Powered air purifying respirators (PAPRs): Some PAPRs provide both respiratory protection and a constant flow of air inside the face shield. This positive airflow helps keep the visor clear and reduces the buildup of heat and moisture.

Forced-air systems: These systems deliver a continuous stream of cool air to the interior of the face shield, helping to maintain a comfortable temperature and minimizing fogging.

Personal cooling devices: Companies have developed compact cooling devices that fit inside the welding helmet or attach to the clothing. These devices use evaporative cooling or small fans to provide a cooling effect during welding.

While these options may provide additional benefits, it’s important to evaluate their compatibility with your specific welding needs and personal comfort.

Understanding Standards for Welding Face Shields

International safety standards for welding face shields

When purchasing a welding face shield, it’s essential to consider whether it meets the necessary safety standards. These standards ensure that the face shield has undergone rigorous testing to meet specific requirements for protection and performance.

Some of the international safety standards applicable to welding face shields include:

ANSI Z87.1: This standard, developed by the American National Standards Institute (ANSI), sets requirements for eye and face protection devices, including face shields. Face shields that comply with ANSI Z87.1 undergo impact testing and must meet specific criteria for optical clarity and coverage.

EN 166: This European standard specifies the requirements for personal eye protection, including face shields. It sets standards for impact resistance, optical properties, and the ability to protect against a range of hazards, including molten metal and extreme temperatures.

These standards ensure that welding face shields meet the necessary safety criteria and provide adequate protection against the hazards associated with welding.

Certifications and markings to look out for when buying face shields

When purchasing a welding face shield, look out for certifications and markings that indicate compliance with safety standards. These certifications provide assurance that the face shield has undergone testing and meets the necessary requirements.

Some common certifications and markings to look out for include:

ANSI Z87.1 certification: Face shields that comply with the ANSI Z87.1 standard will typically have a marking or label indicating their compliance. Look for the ANSI Z87.1 mark on the face shield or its packaging.

CE marking: The CE marking is a mandatory conformity marking for certain products sold within the European Economic Area (EEA), including face shields. It indicates that the product meets the essential health, safety, and environmental protection requirements set out by the European Union.

Ensure that the welding face shield you choose has the necessary certifications and markings to ensure its compliance with safety standards.

How standard compliance impacts face shield safety

Standard compliance plays a significant role in ensuring the safety and effectiveness of welding face shields. Compliance with safety standards means that the face shield has undergone rigorous testing and meets specific criteria for protection and performance. Here are some ways standard compliance impacts face shield safety:

Impact resistance: Welding face shields that comply with safety standards are tested for their ability to withstand impact from flying debris and other hazardous objects. Compliance ensures that the shield provides adequate protection against these hazards.

Optical clarity: Safety standards set requirements for the optical properties of welding face shields. Compliance ensures that the shield offers clear vision without distortion or obstruction, allowing you to see your work clearly and work safely.

Coverage and fit: Standards also specify the coverage and fit requirements for welding face shields. Compliance ensures that the shield adequately covers your face and fits securely, preventing gaps and protecting you from hazards.

By choosing a welding face shield that complies with safety standards, you can have confidence in its ability to provide the necessary protection and ensure your safety during welding operations.

Using Other Purpose-Specific Face Shields

When a welding face shield is not enough

While welding face shields provide excellent protection for most welding applications, there may be instances when additional specialized face shields are required. Here are some situations where a welding face shield may not be enough:

Chemical hazards: If you are working with chemicals or hazardous substances that can cause splashes or airborne droplets, a welding face shield may not provide adequate protection. Consider using a face shield specifically designed for chemical splash protection.

Grinding and cutting: Welding face shields are primarily designed to protect against sparks, debris, and intense light. However, they may not be suitable for protection during grinding and cutting operations, which produce different hazards. In these cases, opt for face shields designed specifically for grinding and cutting activities.

High-heat applications: Some welding processes generate extremely high temperatures that can exceed the capabilities of standard welding face shields. In these cases, specialized face shields that can withstand higher temperatures may be necessary.

Exploring other face shield options for specific welding processes

For specific welding processes or applications, there are face shields available that offer additional features and benefits. Here are some examples:

Tinted lenses: Some welding processes, such as TIG welding, require better visibility of the weld puddle and precise control. Face shields with a clear lens may not provide the necessary clarity. In such cases, look for shields with tinted lenses specifically designed for these processes.

Protection against infrared and radiant heat: Certain welding processes, such as furnace welding or refractory welding, involve exposure to high levels of infrared radiation and radiant heat. Standard welding face shields may not provide adequate protection against these hazards. Consider specialized face shields with additional infrared and radiant heat protection.

Electromagnetic sensitivity: In some cases, welders may have electromagnetic sensitivity or be affected by electromagnetic fields during welding. Specialized face shields with additional electromagnetic shielding can help minimize the impact of electromagnetic radiation.

When exploring face shield options for specific welding processes, consult with experts, manufacturers, and safety professionals to ensure you choose the appropriate protective equipment for your needs.

Combining face shields with other personal protective equipment

While a welding face shield provides essential protection, it should not be the only personal protective equipment (PPE) worn during welding operations. Welders should always consider using additional PPE to ensure comprehensive protection. Here are some examples of other PPE items that can be combined with a welding face shield:

Welding helmet: A welding helmet provides additional protection for your head, neck, and ears. It also offers a more comprehensive shield against sparks, debris, and intense light. Combining a welding helmet with a face shield provides enhanced protection for the face, eyes, and surrounding areas.

Respiratory protection: Depending on the welding environment and the materials being worked on, respiratory hazards such as fumes, gases, or particulate matter may be present. In such cases, it is crucial to wear respiratory protective equipment, such as a respirator or air purifying respirator, in addition to the face shield.

Protective clothing: Welders should always wear appropriate clothing, such as flame-resistant jackets, pants, and gloves, to protect the body from burns, sparks, and flying debris. Welding aprons and sleeves can provide extra protection for specific areas.

By combining a welding face shield with other PPE, you can ensure comprehensive protection against the various hazards associated with welding.

Safety Tips for Beginners

Crucial tips for new welders on face shield use

For beginners in welding, proper use of a face shield is essential for safety. Here are some crucial tips to keep in mind:

Always wear a welding face shield when engaging in welding activities. It should be worn securely, covering your face and eyes completely.

Ensure the face shield fits properly and is positioned at a suitable distance from your eyes. This allows for clear vision and unrestricted movement.

When selecting a face shield, choose one that complies with safety standards and offers the necessary protection against sparks, debris, intense light, and UV radiation.

Regularly inspect your face shield for any signs of damage, such as cracks or scratches. Replace any damaged parts promptly to maintain effectiveness.

Common mistakes beginners make with welding face shields

While using a welding face shield may seem straightforward, beginners can often make certain mistakes that compromise their safety. Here are some common mistakes to avoid:

Improper fit: A common mistake is wearing a face shield that does not fit properly. Ensure the shield covers your entire face and sits snugly against your skin to prevent hazards from entering.

Neglecting maintenance: Beginners may overlook the importance of routine inspection, cleaning, and maintenance of their face shield. Regularly check for damage, clean the shield after each use, and replace any worn-out parts as needed.

Inadequate eye protection: Some beginners may mistakenly assume that a welding face shield alone provides enough eye protection. It’s important to remember that wearing appropriate eye protection underneath the shield, such as safety glasses or goggles, is necessary for added eye safety.

Failure to prioritize safety: In the eagerness to start welding, beginners may prioritize convenience and skip using a face shield altogether or wear it incorrectly. Always prioritize safety by wearing the face shield correctly and consistently throughout the welding process.

Learning to prioritize safety over convenience in welding

As a beginner welder, it is crucial to prioritize safety over convenience. While it may take additional time and effort to properly use and maintain a welding face shield, the long-term benefits far outweigh any inconveniences. By prioritizing safety from the beginning, you establish good habits and ensure a safer and healthier welding experience.

Take the time to understand the importance of safety equipment, including welding face shields, and commit to using them correctly every time you engage in welding activities. Once safety becomes a habit, it will no longer feel like an inconvenience but rather an integral part of your welding routine.

Effect of Face Shields on Visibility and Communication

How face shields affect welder’s visibility

Welding face shields play a significant role in protecting your face and eyes, but they can also impact visibility during welding. Here are some factors to consider regarding visibility when using a face shield:

Tinted lenses: Some welding face shields come with tinted lenses designed to reduce glare and protect your eyes from intense light and harmful UV radiation. While these lenses provide necessary protection, they may darken the overall view, making it more challenging to see certain details or colors.

Lens quality: The quality of the lens in your welding face shield can greatly impact visibility. Look for face shields with high optical clarity and minimal distortion to ensure a clear view of your workpiece.

Fogging: As mentioned earlier, fogging can be a common issue with welding face shields. When the inner surface of the visor fogs up, it can obstruct your vision. Employing anti-fog measures, such as anti-fog coating or ventilation systems, can help minimize this issue.

While welding face shields may introduce certain visibility challenges, it is crucial to strike the right balance between protection and visibility to ensure safe and accurate welding.

Impacts of face shields on communication during welding

Communication is vital in any work environment, and welding is no exception. However, wearing a welding face shield can impact communication, making it more challenging to convey instructions or receive feedback. Here are some ways face shields can affect communication during welding:

Muffled voice: Face shields can create a barrier that absorbs and muffles the sound of your voice, making it harder for others to hear you. Speaking loudly and clearly can help overcome this obstacle.

Visual cues: Communication often relies on visual cues, such as facial expressions and lip movements. While wearing a face shield, these cues are partially or entirely obscured, making it important to rely more on gestures and clear instructions.

Limited peripheral vision: The size and design of the face shield can restrict your peripheral vision, limiting your ability to see others or their movements. It’s crucial to be aware of your surroundings and adjust your positioning accordingly.

Overcoming visibility and communication challenges with proper face shield use

While face shields can affect visibility and communication, it is possible to overcome these challenges with proper face shield use. Here are some tips to ensure effective communication while wearing a face shield:

Speak clearly and loudly: Enunciate your words clearly and speak louder than usual to ensure others can hear you over the sound of welding, even with the face shield on.

Use hand signals and gestures: Utilize hand signals and gestures to convey messages and instructions clearly. This can compensate for the obscured facial expressions and lip movements.

Optimize positioning: Position yourself in a way that allows you to see and be seen by your communication partner. Be mindful of your body and head movements, ensuring that others can observe your gestures and expressions.

Utilize communication systems: In certain environments or situations where face-to-face communication is challenging, consider using alternative forms of communication, such as two-way radios or hand signals that have been agreed upon beforehand.

By being aware of the impact of face shields on visibility and communication and implementing these strategies, you can ensure effective communication with others while maintaining the necessary protection and safety during welding.

Ergonomics of Welding Face Shields

Understanding the relation between face shield design and user comfort

The design of a welding face shield can greatly impact user comfort during welding. Consider the following ergonomic factors when selecting a face shield:

Weight and balance: A face shield that is excessively heavy or poorly balanced can cause discomfort and strain on the head, neck, and shoulders. Look for options that are lightweight and evenly distribute the weight across your head.

Padding and cushioning: Adequate padding and cushioning on the forehead and around the shield’s frame can enhance comfort and prevent pressure points on the skin. High-quality cushioning materials can also absorb sweat, further improving user comfort.

Adjustable features: Face shields with adjustable straps and headbands allow you to customize the fit and achieve an optimal balance of comfort and security. Look for options that provide multiple adjustment points to cater to different head shapes and sizes.

Ventilation systems: Some face shields come with integrated ventilation systems that help improve airflow and reduce heat buildup. This enhances user comfort, especially in hot and humid environments.

Taking these ergonomic factors into consideration when selecting a welding face shield can help ensure a comfortable experience during welding operations.

Long-term impacts of using poorly designed face shields

Using a poorly designed welding face shield can have long-term impacts on your comfort and well-being. Here are some potential issues that may arise from using poorly designed face shields:

Neck and shoulder strain: Improper weight distribution and a lack of proper padding can lead to neck and shoulder strain, especially during extended welding sessions. This strain can result in discomfort, tension, and even chronic pain.

Skin irritation and pressure points: Poorly designed face shields may have rough edges, ill-fitting padding, or inadequate cushioning, leading to skin irritation and pressure points on the forehead and face.

Heat buildup: Insufficient ventilation and poor airflow in a face shield can result in heat buildup, causing excessive sweating, discomfort, and fatigue.

Limited range of motion: Ill-fitting or improperly positioned face shields may restrict your head movements and range of motion, making it harder to perform welding tasks with ease and precision.

To mitigate potential long-term impacts, choose a face shield with ergonomic design features and prioritize comfort, balance, and proper weight distribution.

Exploring advances in ergonomic design of welding face shields

Manufacturers have been making significant advancements in the ergonomic design of welding face shields to enhance user comfort. Here are some notable advances worth exploring:

Lightweight materials: Advances in materials have resulted in lightweight face shields that reduce strain on the head, neck, and shoulders. These shields offer excellent protection without compromising comfort.

Ergonomic headbands: Some face shields feature adjustable headbands with ergonomic designs that conform to the shape of the head, ensuring a secure yet comfortable fit. These headbands may include cushioning materials or pressure-distributing systems for added comfort.

Cooling features: Certain face shields incorporate cooling technologies, such as built-in fans or mechanism that allow airflow, to regulate the temperature inside the shield, reduce heat buildup, and increase user comfort.

Enhanced padding and cushioning: The development of high-quality cushioning materials has resulted in improved comfort and pressure distribution. Look for face shields with well-padded forehead support and comfortable cushioning around the frame for optimum comfort.

By staying informed about the latest advances in the ergonomic design of welding face shields, you can select a shield that meets your comfort needs, allowing you to focus on your welding tasks with reduced fatigue and increased productivity.