Welding PPE, or Personal Protective Equipment, plays a crucial role in ensuring the safety and well-being of welding professionals. But how exactly do you go about properly caring for and maintaining these essential gear? In this article, we will explore practical tips and guidelines to help you keep your welding PPE in top condition, ensuring its effectiveness and longevity. From cleaning and storing to regular inspections and replacements, we’ll cover everything you need to know to extend the lifespan of your welding PPE and stay protected on the job. So let’s get started and discover how you can take better care of your gear!

Understanding the Importance of Welding PPE

Understanding PPE for welders

As a welder, it is crucial to understand the importance of personal protective equipment (PPE). Welding poses numerous hazards, including exposure to intense heat, sparks, and harmful fumes. PPE serves as a barrier between you and these dangers, protecting you from potential injuries.

Appreciation of its role in preventing injuries and improving efficiency

Welding PPE not only safeguards you from harm but also plays a significant role in improving efficiency. By wearing the appropriate protective gear, you can work confidently and focus on the task at hand without worrying about personal safety. This not only reduces the risk of injuries but also ensures that you can work efficiently and effectively.

Recognizing the role of PPE in meeting occupational safety standards

In addition to preventing injuries and enhancing productivity, proper PPE usage is essential for meeting occupational safety standards. Occupational Safety and Health Administration (OSHA) mandates employers to provide their workers with adequate protection against occupational hazards, and this includes welding PPE. By complying with these safety standards, both employees and employers contribute to creating a safe and compliant work environment.

Types of Welding PPE

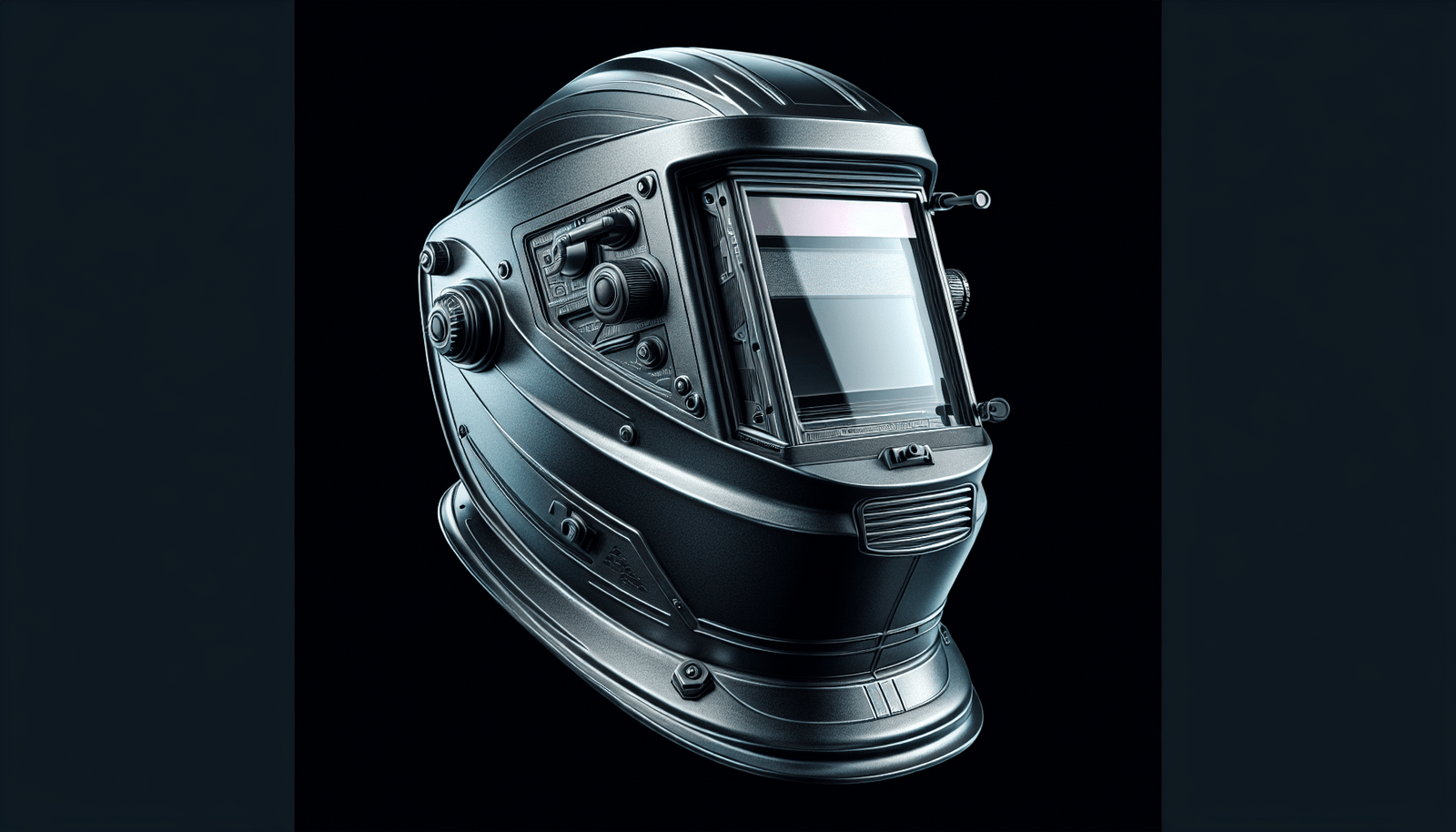

Elaborating on welding helmets and their maintenance

One of the most critical pieces of welding PPE is the welding helmet. It protects your face, eyes, and head from sparks, intense light, and debris. Regular maintenance of your welding helmet is essential to ensure its effectiveness. This involves cleaning the lens, checking the headgear for proper fit, and replacing any damaged parts promptly.

Discussion on welding gloves and how to care for them

Welding gloves are designed to shield your hands from burns, sparks, and electrical shock. Proper care and maintenance are necessary to extend their lifespan and maintain their protective qualities. Regularly inspect your gloves for any signs of wear, clean them as recommended by the manufacturer, and replace them when necessary to ensure optimal safety.

Understanding welding jackets and their proper upkeep

Welding jackets provide full upper body protection, shielding you from radiant heat, molten metal, and sparks. To maintain their effectiveness, it is essential to properly care for your welding jacket. This involves cleaning and inspecting it regularly, ensuring proper storage when not in use, and promptly replacing it if it becomes damaged or worn out.

Proper Storage of Welding PPE

The importance of designated storage

Proper storage of your welding PPE is crucial to ensure its longevity and effectiveness. Designated storage areas protect your equipment from damage, such as exposure to sunlight, moisture, or other environmental factors. Additionally, having a designated storage space ensures that your PPE is readily accessible when needed, promoting a safe and organized work environment.

Steps to properly store welding helmets, gloves, and jackets

When it comes to storing your welding PPE, there are several key steps to follow. Start by cleaning your equipment to remove any debris or contaminants. Next, find a suitable storage area that is dry, away from direct sunlight, and protected from extreme temperatures. Hang your welding jackets and store your helmets and gloves in clean and dry containers to prevent them from getting damaged.

Avoiding damage through correct storage

Proper storage not only ensures the longevity of your welding PPE but also helps prevent damage. Storing helmets, gloves, and jackets in designated areas reduces the risk of accidental damage, such as being stepped on or crushed by other objects. By taking the time to store your PPE correctly, you can prolong its lifespan and maintain its protective properties.

Cleaning Welding PPE

Benefits of regular cleaning of PPE

Regular cleaning of welding PPE offers several benefits, including maintaining its functionality and extending its lifespan. By removing dirt, debris, and contaminants, you ensure that your equipment remains in optimal condition. Clean PPE also promotes good hygiene, reducing the risk of irritation or infection caused by prolonged contact with contaminants.

Proper cleaning procedures for various types of PPE

Different types of welding PPE require specific cleaning procedures to ensure their effectiveness. For welding helmets, clean the lens using appropriate cleaning solutions and a soft cloth, taking care not to scratch the lens. Welding gloves can generally be cleaned with soap and water, followed by air drying. Welding jackets may need specialized cleaning methods, such as spot cleaning or professional dry cleaning, depending on the material.

Recognizing when professional cleaning is needed

While regular cleaning can address most maintenance needs, some situations may require professional cleaning. If your welding PPE has stubborn stains, odors, or has come into contact with hazardous substances, it is best to seek professional cleaning services. Certified professionals have the knowledge and equipment to effectively clean your PPE without compromising its protective qualities.

Inspection of Welding PPE

Importance of continuous inspection of PPE

Regular inspection of welding PPE is essential to identify any signs of damage, wear, or deterioration. By inspecting your equipment before each use, you can ensure that it meets the necessary safety standards and provides adequate protection. Inspecting your PPE is a proactive approach that allows you to address any issues promptly, reducing the risk of accidents or injuries.

Checklist for inspecting welding PPE

When inspecting your welding PPE, consider the following checklist:

- For welding helmets, check the condition of the lenses, headgear, and any adjustable features.

- Examine your welding gloves for any signs of wear, such as holes or fraying seams.

- Inspect welding jackets for any damage, including burn holes, tears, or worn-out fasteners.

- Ensure that all PPE fits properly and provides adequate coverage.

Steps to take when PPE fails inspection

If your welding PPE fails inspection, it is crucial to take immediate action. Remove the equipment from service and replace it with new, properly functioning PPE. By promptly addressing any issues, you can ensure your safety and maintain compliance with occupational safety regulations.

Replacement of Welding PPE

Understanding the life expectancy of different PPE

It is essential to understand the life expectancy of your welding PPE to ensure its continued effectiveness. While the lifespan varies depending on factors such as the frequency of use and the level of exposure to hazards, most PPE, including helmets, gloves, and jackets, typically have a finite lifespan. Familiarize yourself with the expected lifespan of your equipment and regularly monitor their condition for signs of wear or damage.

Identifying signs when PPE needs replacement

As your welding PPE ages, several signs indicate the need for replacement. These signs may include visible damage, such as holes, tears, or deterioration of materials. Functionality issues, such as broken fasteners or worn-out adjustability, also indicate the need for replacement. Additionally, if your PPE no longer fits properly or provides adequate protection, it is time to replace it.

Proper disposal and replacement process for old PPE

When disposing of old welding PPE, it is important to follow proper guidelines to ensure the safety of both you and the environment. Most PPE cannot be recycled and should be discarded in accordance with local regulations. To replace your old PPE, consult reputable suppliers or manufacturers who can advise you on suitable replacements based on your needs and ensure compliance with safety standards.

Training on Welding PPE Care and Maintenance

Importance of training in PPE maintenance

Training in proper care and maintenance of welding PPE is vital for welders. It ensures that you have the knowledge and skills to maintain your equipment correctly, reducing the risk of accidents and injuries. Through training, you learn about the specific requirements for cleaning, inspecting, and replacing your PPE, fostering a safe working environment.

Types of training courses available

Various training courses are available to provide welders with the necessary knowledge and skills in PPE care and maintenance. These courses may be offered by welding schools, safety organizations, or equipment manufacturers. They cover topics such as proper cleaning procedures, inspection techniques, and understanding when PPE needs replacement. Consider enrolling in these courses to enhance your expertise in PPE maintenance.

Outcomes and benefits of PPE care training

By undergoing training in PPE care and maintenance, you can reap numerous benefits. You will be equipped with the knowledge to extend the lifespan of your equipment and ensure its ongoing effectiveness. Training can also increase your awareness of occupational hazards and the importance of complying with safety regulations. Ultimately, proper PPE care training contributes to a safer work environment and your overall professional development as a welder.

PPE Maintenance and COVID-19

Extra precautions to take during the pandemic

In light of the COVID-19 pandemic, it is essential to take additional precautions when maintaining your welding PPE. Follow the recommended health guidelines, such as wearing gloves while handling your equipment and practicing proper hand hygiene. Minimize contact with others and avoid sharing your PPE to reduce the risk of transmission. Adhering to these precautions ensures both your safety and the safety of those around you.

Cleaning and sanitizing PPE in light of COVID-19

Regular cleaning and sanitizing of your welding PPE are more critical than ever during the COVID-19 pandemic. Clean your equipment thoroughly using appropriate cleaning agents or solutions recommended by health authorities. Pay extra attention to frequently touched surfaces, such as the headgear on welding helmets or fasteners on jackets. By maintaining cleanliness and sanitization, you can reduce the potential transmission of the virus.

Adjustments to PPE usage and maintenance due to coronavirus

To align with COVID-19 safety protocols, certain adjustments may need to be made to your PPE usage and maintenance routines. For example, you may need to wear a face covering or mask in addition to your welding helmet to provide an extra layer of protection. Consider implementing additional cleaning measures, such as more frequent sanitization, to ensure the safety of yourself and others in the face of the pandemic.

Legal and Regulatory Compliance in PPE Care

Overview of relevant safety regulations

In the welding industry, several safety regulations govern the care and maintenance of PPE. These regulations are designed to ensure the highest level of protection for workers. Familiarize yourself with the regulations applicable to your jurisdiction, such as those set forth by OSHA or industry-specific standards. By understanding and adhering to these regulations, you contribute to a safer working environment and avoid potential penalties.

Responsibilities employers hold according to law

Employers have significant responsibilities regarding the care and maintenance of welding PPE. They are obligated to provide appropriate PPE to their employees, maintain it in good condition, and ensure that workers receive proper training on its use and maintenance. Employers must also establish protocols for inspecting, replacing, and disposing of PPE in accordance with safety regulations.

Penalties associated with compliance failures

Failure to comply with safety regulations regarding PPE care and maintenance can result in penalties for employers. These penalties may include fines, legal repercussions, or potential suspension of operations. Additionally, non-compliance poses serious risks to the safety and well-being of workers. By prioritizing compliance, employers not only avoid penalties but also protect their employees and uphold their legal obligations.

PPE Care and Maintenance Best Practices

Advice from leading professionals in welding safety

Leading professionals in welding safety offer valuable advice on PPE care and maintenance. Their insights can help you enhance your knowledge and skills in maintaining your equipment. Look for resources, such as articles, books, or online forums, where experts share their recommendations. By incorporating their best practices into your own routines, you can ensure optimal safety and extend the lifespan of your welding PPE.

Industry standard tips and practices

The welding industry has established various standards, tips, and practices regarding PPE care and maintenance. These guidelines are based on extensive research and industry expertise, representing the collective knowledge of professionals in the field. Access industry resources, such as safety manuals or websites, to familiarize yourself with these standards. By following industry best practices, you can promote a culture of safety and maintain the highest level of protection.

Caught on tape: real-life examples of correct and incorrect PPE maintenance

Real-life examples serve as powerful learning tools when it comes to PPE care and maintenance. By observing actual situations and outcomes, you can better understand the consequences of both correct and incorrect practices. Look for videos or case studies that showcase incidents related to PPE maintenance. These visual representations can enhance your understanding and reinforce the importance of proper care and maintenance in welding safety.

In conclusion, understanding the importance of welding PPE is crucial for ensuring safety, improving efficiency, and meeting occupational safety standards. By familiarizing yourself with the types of welding PPE, proper storage, cleaning procedures, inspection, replacement, and training, you can effectively care for and maintain your equipment. Adapting to additional precautions during the COVID-19 pandemic, complying with legal and regulatory requirements, and incorporating best practices from industry professionals and standards further contribute to a safe welding environment. Remember, your commitment to PPE care and maintenance plays a vital role in protecting yourself and others in the welding industry.