If you’re a welding professional, you understand the importance of safety gear. It not only protects you from potential hazards but also ensures that you can work efficiently and confidently. But with so many options available, which safety gear should you invest in? In this article, we will explore the most popular welding safety gear among professionals. From helmets to gloves and everything in between, we’ll provide you with valuable insights to help you make informed decisions and prioritize your safety on the job. So, let’s dive in and discover the must-haves for welders like yourself!

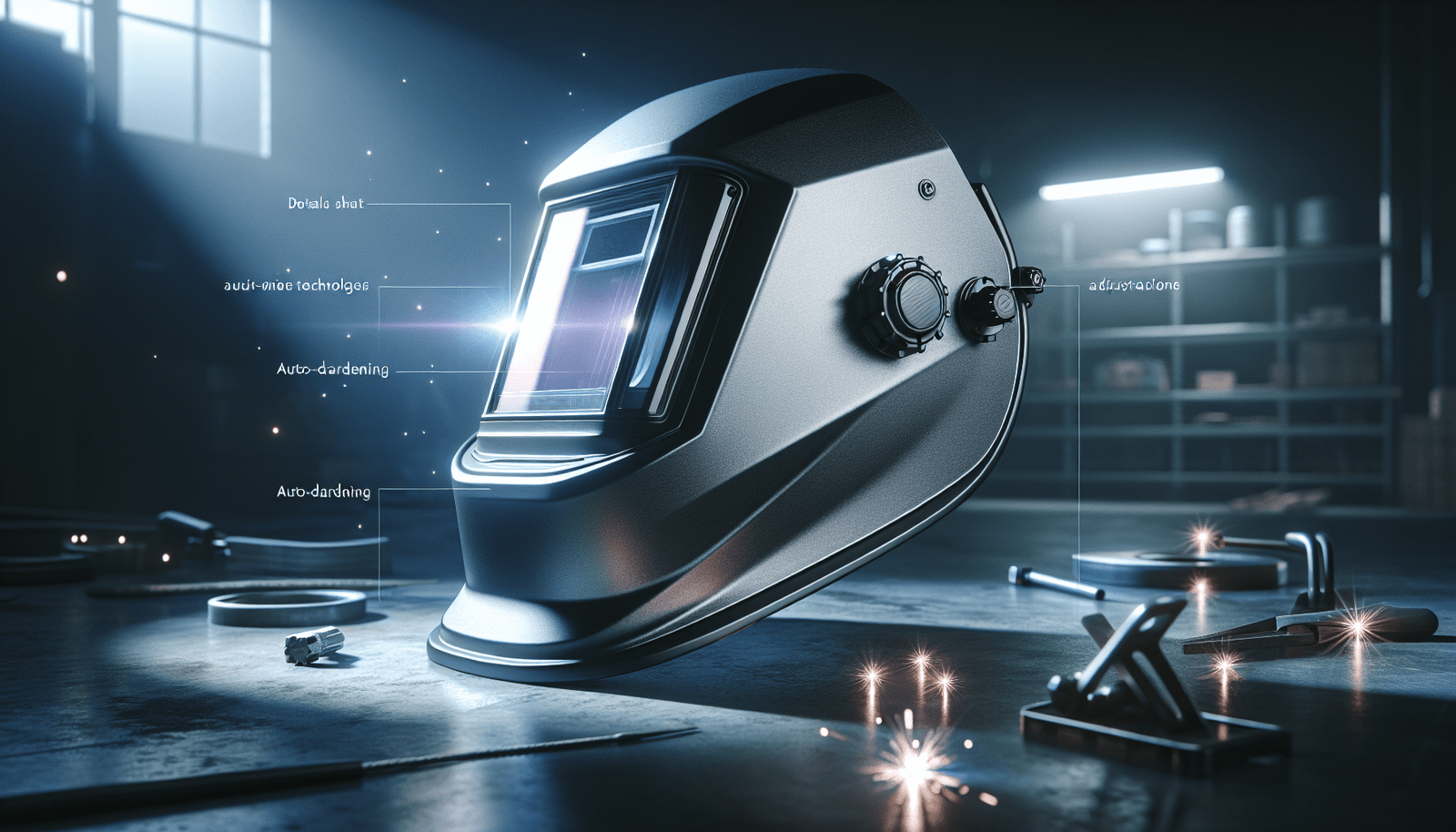

Auto-Darkening Welding Helmets

Definition and Importance

An auto-darkening welding helmet is a crucial piece of safety gear designed for welders. It provides protection to your eyes and face by shielding you from the harmful effects of welding arcs and sparks. These helmets are equipped with an auto-darkening filter, which automatically adjusts the shade of the lens to protect your eyes from the intense light emitted during welding.

The importance of using an auto-darkening welding helmet cannot be overstated. Welding involves working with high-intensity light and heat, and without proper eye protection, welders are at risk of developing serious eye conditions such as arc eye, also known as welder’s flash. This condition can cause extreme pain, sensitivity to light, and temporary blindness. Therefore, investing in a high-quality auto-darkening welding helmet is essential for your safety and well-being.

Key Features to Consider

When choosing an auto-darkening welding helmet, there are several key features to consider. These features ensure that you have a helmet that not only provides excellent protection but also offers comfort and convenience during your welding tasks.

Lens Shade Range: Look for a helmet with an adjustable lens shade range that suits the type of welding you will be doing. Different welding processes and materials may require different levels of darkness, so having a helmet with a wide shade range allows you to adjust the lens accordingly.

Reaction Time: The reaction time of the auto-darkening filter is another important feature to consider. This refers to the time it takes for the lens to transition from its light state to the dark state once an arc is struck. A faster reaction time ensures that your eyes are protected instantaneously, reducing the risk of exposure to harmful light.

Sensitivity and Delay Controls: Helmets with sensitivity and delay controls allow you to customize the response of the auto-darkening filter. Sensitivity controls help in adjusting the helmet’s reaction to ambient light, while delay controls determine how long the lens stays dark after the welding arc stops. Having control over these settings enhances your overall welding experience.

Comfort and Fit: Consider the overall comfort and fit of the welding helmet. Look for features such as adjustable headgear, padding, and lightweight materials. A well-fitting helmet will ensure that you can work for extended periods without discomfort or strain on your neck.

Power Source: Auto-darkening welding helmets typically rely on batteries or solar power to operate. Choose a helmet that suits your preferences and working environment. Battery-powered helmets offer convenience but require regular battery replacement, while solar-powered helmets are more environmentally friendly and are ideal for outdoor welding.

By considering these key features, you can select an auto-darkening welding helmet that provides optimal protection, comfort, and functionality for your specific welding needs.

Top Brands

Several reputable brands offer high-quality auto-darkening welding helmets. Here are some of the top brands known for their exceptional products:

Lincoln Electric: Lincoln Electric is a renowned name in the welding industry, and their auto-darkening welding helmets are highly regarded for their durability and performance. Their helmets feature advanced technology, superior optics, and reliable arc sensing capabilities.

Miller Electric: Miller Electric is another trusted brand that produces top-notch welding equipment. Their auto-darkening helmets are known for their excellent visibility, innovative features, and user-friendly designs. Miller Electric offers a wide range of models to cater to different welding applications.

3M Speedglas: 3M Speedglas is a leading brand specializing in welding safety gear. Their auto-darkening welding helmets are known for their exceptional optical clarity, comfort, and reliability. 3M Speedglas helmets often incorporate advanced features such as respiratory protection and customizable settings.

Jackson Safety: Jackson Safety is a popular brand offering a wide selection of welding helmets. Their auto-darkening helmets are designed to meet the demands of professional welders. Jackson Safety helmets are known for their durability, comfort, and superior protection.

When choosing an auto-darkening welding helmet, consider these top brands and explore their product offerings to find the helmet that best suits your needs and preferences. Remember, investing in a reputable brand ensures that you are getting a quality helmet that will keep you safe while welding.

Welding Respirators

What is a Welding Respirator

A welding respirator is an essential piece of safety equipment that protects welders from inhaling harmful fumes and particles produced during the welding process. It filters the air, removing contaminants and ensuring that the air you breathe is clean and safe.

Welding fumes can contain harmful substances such as metal oxides, gases, and vapors, which can lead to serious health issues if inhaled regularly or in high concentrations. Prolonged exposure to these fumes can cause respiratory problems, lung diseases, and even cancer. Therefore, wearing a welding respirator is crucial for maintaining your respiratory health while working in welding environments.

Different Types of Welding Respirators

There are various types of welding respirators available, each offering different levels of protection and suitability for specific welding applications. Here are the most common types:

Disposable Respirators: Disposable respirators, also known as filtering facepiece respirators (FFRs), are lightweight and inexpensive options for short-duration welding tasks. They are designed to filter out airborne particles but may not provide comprehensive protection against certain gases and vapors. Disposable respirators are typically discarded after use.

Half-Mask Respirators: Half-mask respirators cover your nose and mouth, providing both particle and gas/vapor filtration. They consist of a facepiece and replaceable filters. Half-mask respirators offer more protection than disposable respirators and are suitable for moderate to heavy-duty welding tasks.

Full-Face Respirators: Full-face respirators provide the highest level of protection as they cover the entire face, including the eyes and respiratory system. They typically have built-in eye protection in the form of a clear visor or face shield. Full-face respirators are recommended for tasks involving high levels of airborne contaminants or when additional eye protection is required.

Powered Air Purifying Respirators (PAPRs): PAPRs are equipped with a powered fan that supplies filtered air to the user. They offer a higher degree of comfort as they reduce breathing resistance and provide constant airflow. PAPRs are suitable for extended welding tasks or environments with high concentrations of contaminants.

Choosing the Right Welding Respirator

To choose the right welding respirator, consider the following factors:

Filtration Efficiency: Ensure that the respirator you choose provides adequate filtration efficiency against the specific contaminants present in your welding environment. Look for respirators with NIOSH (National Institute for Occupational Safety and Health) approval to ensure they meet industry standards.

Comfort and Fit: A properly fitting respirator is essential for effective protection. Look for adjustable straps, cushioned nosepieces, and a good seal around your face. The respirator should be comfortable to wear for extended periods without causing discomfort or impairing your ability to work.

Compatibility with Other PPE: If you wear other personal protective equipment (PPE), such as welding helmets or safety glasses, ensure that the respirator is compatible and does not interfere with the proper fit of these equipment.

Ease of Use and Maintenance: Consider how easy it is to use and maintain the respirator. Look for features such as replaceable filters, easy filter change systems, and straightforward cleaning procedures. Regular maintenance and filter replacement are crucial for ensuring the effectiveness of your respirator.

Consult with safety experts or professionals in the welding industry to help you choose the right welding respirator based on your specific welding tasks and exposure hazards. Prioritizing respiratory safety is essential for your long-term health and well-being as a welder.

Welding Jackets

Why Welding Jackets are Essential

Welding jackets are a vital component of a welder’s personal protective equipment (PPE) and provide essential protection against sparks, hot metal, and the intense heat generated during welding. They are designed to be flame-resistant and, in some cases, even cut-resistant, ensuring that your upper body is safeguarded while working in high-risk welding environments.

Welding involves working with extreme heat, flying sparks, and molten metal, all of which present significant hazards to the exposed skin. Welding jackets, with their durable construction and fire-resistant materials, create a protective barrier between the welder’s body and these potential dangers. They significantly reduce the risk of burns, cuts, and other injuries, allowing you to focus on your welding tasks with peace of mind.

Materials Used for Welding Jackets

Welding jackets are made from specialized materials that provide excellent resistance to heat, sparks, and flames. The choice of material depends on the specific requirements of the welding task and the level of protection necessary. Here are some common materials used in welding jackets:

Leather: Leather is a popular choice for welding jackets due to its exceptional durability and heat resistance. It provides excellent protection against sparks and molten metal splatter, making it ideal for heavy-duty welding applications. Leather jackets are typically made from high-quality cowhide or goatskin leather.

Flame-Resistant Cotton: Flame-resistant cotton, often referred to as FR cotton, is another commonly used material in welding jackets. It is treated with flame-retardant chemicals to enhance its fire-resistant properties. FR cotton jackets offer good protection against sparks and light welding hazards, while also providing a high level of comfort and breathability.

WeldX: WeldX is a proprietary fabric developed specifically for welding applications. It is a combination of flame-resistant fibers and Kevlar, making it highly resistant to heat, flames, and welding spatter. WeldX jackets are known for their excellent durability, flexibility, and lightweight design, providing optimal comfort and protection.

Aluminized Fabrics: Aluminized fabrics are composed of a substrate material, such as fiberglass or para-aramid, coated with a layer of aluminum. This coating reflects radiant heat and provides excellent thermal protection. Aluminized jackets are commonly used in high-heat welding processes, such as furnace maintenance and metal casting.

When choosing a welding jacket, ensure that it meets industry safety standards and is appropriate for the specific welding tasks you will be performing. Consider factors such as the level of heat resistance, abrasion resistance, and flexibility offered by the material. Additionally, ensure that the jacket fits well and allows for freedom of movement, as this is essential for comfort and safety during welding operations.

Top-Rated Welding Jackets

There are several top-rated welding jacket brands known for their quality and performance. Here are a few brands worth considering when choosing a welding jacket:

Tillman: Tillman is a respected brand in the welding industry, known for its high-quality protective gear. Tillman welding jackets are made from durable materials, offer excellent heat resistance, and come in various styles to suit different welding applications.

Black Stallion: Black Stallion is committed to providing advanced protection for welders. Their welding jackets combine functionality and style, incorporating features such as reinforced stitching, adjustable cuffs, and numerous pockets for storage convenience.

Lincoln Electric: Lincoln Electric is a trusted name in welding equipment, and their welding jackets live up to their reputation. Their jackets are available in both leather and flame-resistant cotton variants, designed to withstand the rigors of welding environments while ensuring comfort and safety.

Revco Industries: Revco Industries specializes in welding safety products, and their welding jackets are highly regarded for their quality and durability. Revco welding jackets feature innovative designs, clever storage solutions, and excellent heat resistance, making them a popular choice among welders.

These top-rated brands have established themselves as leaders in the welding industry by providing welders with reliable and high-performance welding jackets. Remember to choose a welding jacket that meets your specific safety requirements and offers the necessary level of protection for your welding tasks.

Welding Gloves

Role of Welding Gloves in Safety

Welding gloves are an integral part of a welder’s personal protective equipment (PPE) and play a crucial role in ensuring safety during welding operations. They provide protection to your hands and forearms from heat, sparks, flames, and molten metal splatter generated during the welding process.

The extreme temperatures involved in welding pose serious hazards to exposed skin. Without proper hand protection, welders are susceptible to burns, cuts, and other injuries. Welding gloves act as a barrier between your hands and the potential hazards present in the welding environment, significantly reducing the risk of injury and ensuring your safety.

Choosing the Right Material and Size

Welding gloves are available in various materials, each offering different levels of protection, dexterity, and durability. Furthermore, selecting the right size of gloves is crucial to ensure a comfortable and secure fit. Here are some key factors to consider when choosing welding gloves:

Material: Common materials used in welding gloves include leather, split leather, and composite fabrics. Leather gloves, such as cowhide or goatskin, provide excellent heat resistance, durability, and protection against welding spatter. Split leather gloves, made from the lower layers of leather, offer enhanced flexibility while maintaining good heat resistance. Composite fabrics, such as Kevlar or Nomex, provide excellent cut and abrasion resistance in addition to heat protection.

Stitching: Pay attention to the stitching on the gloves, as it affects their durability and ability to withstand the rigors of welding. Look for gloves with reinforced or flame-resistant stitching for added strength and protection.

Cuff Length: Welding gloves come in different cuff lengths, ranging from short cuffs that cover the wrist to long cuffs that extend over the forearm. The choice of cuff length depends on the level of protection required and personal preference. Longer cuffs offer greater coverage and protection against sparks, while shorter cuffs allow for more flexibility and ease of movement.

Size and Fit: Choosing the correct size of welding gloves is essential for comfort and safety. Gloves that are too tight may restrict movement and cause discomfort, while gloves that are too loose may compromise dexterity and increase the risk of injury. Refer to manufacturer sizing charts and try gloves on before purchasing to ensure a proper fit.

Leading Welding Glove Brands

When it comes to welding gloves, certain brands are highly regarded for their reliable and high-quality products. Here are some leading welding glove brands to consider:

Tillman: Tillman is a well-known name in the welding industry and offers a range of welding gloves suitable for various applications. Tillman gloves are known for their durability, heat resistance, and excellent grip. They are designed to provide superior protection and comfort for welders.

Revco Industries: Revco Industries specializes in welding safety gear, including welding gloves. Their gloves are constructed to withstand high temperatures, sparks, and abrasions, while also offering a comfortable fit. Revco Industries focuses on innovation and uses high-quality materials to ensure top-notch performance.

Lincoln Electric: Lincoln Electric is a trusted brand in the welding world, known for its high-quality welding equipment and safety gear. Lincoln Electric gloves are designed with the needs of professional welders in mind, offering excellent heat resistance, dexterity, and ergonomic designs.

Black Stallion: Black Stallion is committed to providing welders with reliable and functional welding gloves. Their gloves feature durable materials, reinforced palm and fingertip areas for longevity, and excellent heat protection. Black Stallion gloves offer a balance between protection and flexibility, allowing for precise hand movements during welding.

By choosing gloves from these leading brands, you can trust that you are investing in quality welding gloves that prioritize your safety and provide optimal protection for your hands and forearms.

Welding Safety Glasses

Eye Protection in Welding

Eye protection is of paramount importance in welding, as exposure to intense light, sparks, and flying debris can cause severe eye injuries. Welding safety glasses are specially designed to shield your eyes from these hazards, ensuring your visual health and safety while working.

During welding, intense ultraviolet (UV) and infrared (IR) radiation is emitted, which can damage the eyes and even lead to long-term vision problems. Additionally, the bright arc light can cause temporary or permanent blindness if proper eye protection is not used. Welding safety glasses are equipped with filters that block harmful UV and IR radiation, allowing you to work comfortably and safeguarding your vision.

Criteria for Selecting Safety Glasses

When selecting welding safety glasses, it is important to consider various criteria to ensure that they provide effective protection and meet your specific needs. Here are some important factors to consider:

Shade Level: The shade level of the safety glasses determines the amount of light they filter out. Different welding processes require different shade levels, so choose glasses that are appropriate for the type of welding you will be performing. Refer to industry guidelines and standards to determine the recommended shade level for your specific welding application.

Material and Durability: Look for safety glasses made from durable materials such as polycarbonate, which offer resistance to impact and scratches. These materials are lightweight and comfortable to wear for extended periods without compromising on strength and durability.

Lens Coating: Some safety glasses have special lens coatings to enhance their performance. Anti-fog coatings help prevent the lenses from fogging up during welding, which can obstruct your vision. Anti-scratch coatings prolong the life of the glasses, ensuring clear visibility and maintaining their protective properties.

Fit and Comfort: Safety glasses should fit your face comfortably and securely without causing discomfort or slipping off. Look for glasses with adjustable temples and nosepieces to achieve a proper fit. Consider styles that offer wrap-around designs for increased protection and coverage.

Compatibility with Other PPE: If you wear other PPE, such as welding helmets or respirators, ensure that the safety glasses are compatible and do not interfere with the proper fit or functionality of the other equipment.

Best Safety Glasses for Welding

Several safety glasses brands offer reliable eye protection for welding professionals. Here are some popular brands that are known for their quality and performance:

3M: 3M is a reputable brand known for its wide range of safety products. Their welding safety glasses provide excellent UV and IR protection while offering superior optical clarity. 3M safety glasses feature durable construction, comfortable fit, and various shade options to suit different welding applications.

Lincoln Electric: Lincoln Electric offers welding safety glasses that meet industry standards and provide reliable eye protection. Their glasses feature wrap-around designs for enhanced coverage, adjustable temples for a secure fit, and high-quality lenses for clear visibility.

Gateway Safety: Gateway Safety specializes in eye and face protection, and their welding safety glasses are no exception. Their glasses are designed for optimal comfort, durability, and protection. Gateway Safety glasses often incorporate anti-fog and anti-scratch coatings, ensuring clear vision and longevity.

Jackson Safety: Jackson Safety is a trusted brand in the welding industry, known for its commitment to safety and quality. Their welding safety glasses combine style, comfort, and functionality. With options for different shade levels and lens coatings, Jackson Safety ensures that their glasses meet the specific needs of welders.

Choosing safety glasses from these reputable brands gives you confidence in the effectiveness and durability of your eye protection. Remember to prioritize eye safety by wearing safety glasses at all times during welding operations and replacing them according to manufacturer recommendations or if they become damaged.

Welding Caps and Bandanas

Why Head Protection is Needed

Head protection is an essential aspect of welding safety, as it helps guard against potential hazards such as sparks, hot metal, and UV radiation. Welding caps and bandanas are designed to provide a protective barrier for your head, as well as offer comfort, absorb sweat, and prevent hair from falling into your work area.

During welding, sparks and molten metal can fly in all directions, posing threats to your face, head, and hair. UV radiation emitted during welding can also cause burns and damage to the scalp and hair. Welding caps and bandanas are made from flame-resistant materials that provide insulation and protect your head from these hazards.

Factors to Consider When Buying

When buying a welding cap or bandana, consider the following factors to ensure you choose a product that suits your needs:

Material: Welding caps and bandanas are typically made from flame-resistant cotton or Kevlar. Flame-resistant cotton offers a lightweight and breathable option, while Kevlar is known for its exceptional durability and heat resistance. Choose a material that provides the level of protection and comfort required for your welding tasks.

Coverage: Consider the coverage provided by the cap or bandana. Caps with a brim or bill offer additional protection for your face and eyes, shielding them from sparks and glare. Bandanas, on the other hand, provide coverage for the scalp and hair, preventing them from exposure to sparks and heat.

Size and Fit: Ensure that the cap or bandana fits securely on your head without causing discomfort or slipping. Some caps and bandanas come in adjustable sizes or have elastic bands for a customized fit. It is important to have a secure fit to prevent them from falling off or becoming a hazard during welding.

Style and Design: Welding caps and bandanas come in various styles and designs. Choose a style that suits your preference, but prioritize functionality and safety over aesthetics. Look for features such as sweatbands for added comfort and snaps or ties to secure the cap or bandana in place.

Popular Brands of Welding Caps and Bandanas

Several brands specialize in welding caps and bandanas, offering products that combine style and functionality. Here are a few popular brands worth considering:

BSX Gear: BSX Gear is a well-known brand among welders and offers a range of high-quality welding caps and bandanas. Their products feature durable construction, fire-resistant materials, and eye-catching designs. BSX Gear combines style with functionality to provide welders with comfortable and protective headgear.

Jackson Safety: Jackson Safety is a trusted name in the welding industry and offers a variety of welding caps and bandanas. Their headgear is designed to meet safety standards while providing a secure fit and stylish appearance. Jackson Safety is known for its focus on quality and user satisfaction.

Tillman: Tillman is a reputable brand that has been manufacturing welding safety gear for many years. Their caps and bandanas deliver reliable protection and come in various sizes and designs to cater to different preferences. Tillman caps are made from flame-resistant materials, ensuring optimal safety in welding environments.

When selecting a welding cap or bandana, choose a reputable brand that prioritizes safety and durability. Consider the specific hazards you will be exposed to during welding and select headgear that offers adequate protection and comfort. Whether you opt for a cap with a brim or a bandana, wearing head protection is crucial for maintaining your safety and preventing potential injuries.

Welding Ear Protection

Importance of Ear Protection

Ear protection is often overlooked in welding safety discussions, but it is an essential aspect of protecting your overall health and well-being. Welding produces loud and potentially damaging noise that can lead to hearing loss if proper precautions are not taken. Welding ear protection, such as earplugs or earmuffs, help reduce the risk of hearing damage caused by prolonged exposure to high levels of noise.

Welding processes generate sound levels that can exceed the safe limit of 85 decibels (dB). Prolonged exposure to these elevated noise levels can result in permanent hearing loss or other hearing-related conditions such as tinnitus (ringing in the ears). Therefore, using appropriate ear protection is crucial for preserving your hearing and preventing long-term damage.

Types of Ear Protection

There are various types of ear protection available for welders, each offering different levels of noise reduction and comfort. Here are the most common types:

Disposable Earplugs: Disposable earplugs are made of foam or soft silicone and are designed to be inserted into the ear canal. They provide a snug fit and effectively block out noise. Disposable earplugs are convenient, affordable, and suitable for single-use applications.

Reusable Earplugs: Reusable earplugs are made of durable materials such as silicone or thermoplastic elastomer (TPE). They can be cleaned and reused, making them a cost-effective option for frequent welding tasks. Reusable earplugs often come with interchangeable filters to customize the level of noise reduction.

Earmuffs: Earmuffs consist of padded ear cups connected by a headband. They cover the entire ear and create a seal to block out noise. Earmuffs generally offer a higher level of noise reduction compared to earplugs. Some earmuffs also incorporate electronic features, such as amplification or noise-cancellation, to enhance communication while still providing protection against harmful noise levels.

Custom-Molded Earplugs: Custom-molded earplugs are individually crafted to fit the unique shape of your ear for maximum comfort and noise reduction. They are typically made by taking an ear impression and creating a custom mold. While they may be more expensive, custom-molded earplugs offer an optimal and long-lasting solution for ear protection.

Best Welding Ear Protection Gear

Selecting the best welding ear protection gear depends on your specific needs, comfort preferences, and the noise levels encountered during your welding tasks. Here are a few trusted brands known for their quality ear protection products:

Howard Leight: Howard Leight offers a wide range of ear protection solutions for various industries, including welding. Their earplugs and earmuffs deliver excellent noise reduction, comfort, and durability, ensuring optimal hearing protection during welding operations.

3M Peltor: 3M Peltor specializes in hearing protection products and is a trusted name in the industry. Their earmuffs are designed to provide superior noise reduction and fit securely for long periods. 3M Peltor earmuffs often incorporate advanced features, such as Bluetooth connectivity and rechargeable batteries, for added convenience.

Moldex: Moldex offers a selection of earplugs and earmuffs that meet stringent industry standards for hearing protection. Their products provide excellent noise reduction and are known for their comfort and ease of use. Moldex earplugs come in various sizes and styles to cater to different ear shapes and preferences.

Remember, when selecting welding ear protection gear, check that the products meet or exceed applicable noise reduction standards. Consider factors such as comfort, ease of use, and whether the ear protection is compatible with other PPE, such as welding helmets or respirators. Prioritizing ear safety is essential to protect against hearing damage and maintain your overall well-being as a welder.

Welding Boot Covers

Purpose and Usage of Boot Covers

Welding boot covers are an important part of a welder’s personal protective equipment (PPE), providing protection for your feet and lower legs in high-risk welding environments. They are designed to be worn over regular work boots or shoes and act as a shield against sparks, hot metal shards, and falling objects.

Welding processes generate intense heat, molten metal splatter, and flying debris, all of which pose significant hazards to the exposed skin and footwear. Welding boot covers, typically made from flame-resistant materials, provide a protective barrier between your boots and these potential dangers. They significantly reduce the risk of burns, cuts, and other injuries, ensuring your safety while working.

Choosing the Right Boot Covers

When choosing welding boot covers, consider the following factors to ensure they provide effective protection and meet your specific needs:

Material: Welding boot covers are typically made from flame-resistant materials such as leather or flame-resistant cotton. Leather boot covers offer excellent heat resistance, durability, and protection against welding spatter. Flame-resistant cotton boot covers provide a lightweight and breathable option while still offering good heat and abrasion resistance.

Coverage: Consider the coverage provided by the boot covers. They should adequately cover your work boots or shoes to prevent sparks, hot metal, or other debris from entering your footwear. Look for boot covers with height options that suit your needs, providing sufficient coverage for your specific welding applications.

Fit and Closure: The boot covers should fit securely over your work boots or shoes without impeding your movements or causing discomfort. Look for boot covers with adjustable straps or closures to ensure a snug fit. This prevents the covers from slipping off or becoming a safety hazard during welding operations.

Durability: Welding boot covers should be made from durable materials that can withstand the rigors of welding environments. Look for features such as reinforced stitching or additional layers of material in high-wear areas to ensure longevity and optimal protection.

Recommended Brands for Welding Boot Covers

Several reputable brands specialize in welding safety gear, including welding boot covers. Here are a few recommended brands known for their quality and performance:

Black Stallion: Black Stallion offers a range of welding boot covers designed to provide reliable protection and comfort. Their boot covers are made from flame-resistant materials, offering heat resistance and durability. Black Stallion boot covers often feature adjustable straps and quality construction for a secure fit.

Tillman: Tillman is a well-known name in the welding industry and offers a variety of welding safety gear, including boot covers. Their boot covers are designed to withstand the demands of welding environments, providing excellent heat resistance and coverage. Tillman boot covers are known for their quality craftsmanship and innovative features.

Lincoln Electric: Lincoln Electric is a trusted brand in welding equipment and safety gear. Their welding boot covers are designed to provide reliable protection and comfort. Lincoln Electric boot covers often feature high-quality materials, adjustable closures, and rugged construction for durability.

Choosing boot covers from reputable brands ensures that you are investing in quality products that prioritize your safety and provide optimal protection for your feet and lower legs. Remember to select boot covers that meet industry safety standards and are appropriate for the specific welding tasks you will be performing.

Leather Welding Aprons

Significance of Welding Aprons

Welding aprons are an important piece of personal protective equipment (PPE) for welders, providing essential protection against sparks, heat, and flying debris. They are designed to cover the upper body and lower limbs, shielding welders from potential hazards during welding operations.

Welding involves working with intense heat, sparks, and molten metal, all of which pose significant risks to exposed skin and clothing. Welding aprons, often made from durable leather, create a protective barrier, reducing the risk of burns, cuts, and other injuries. They prevent sparks and hot metal splatter from reaching the body, ensuring your safety while working.

Choosing the Perfect Leather Welding Apron

When choosing a leather welding apron, there are several factors to consider to ensure it provides effective protection, comfort, and durability. Here are some key factors to keep in mind:

Material: Leather welding aprons are typically made from cowhide, goatskin, or a combination of high-quality leathers. These materials offer excellent flame resistance, heat resistance, and durability. Choose a material that suits your needs, considering factors such as weight, flexibility, and abrasion resistance.

Length: The length of the welding apron is crucial as it determines the extent of coverage and protection provided. Look for aprons that cover the entire torso and extend beyond the knees, ensuring that the legs are adequately shielded. A longer apron offers better protection against sparks, hot metal, and flying debris.

Weight and Comfort: Consider the weight of the apron and its impact on comfort. While heavy-duty aprons provide excellent protection, they can be cumbersome to wear for extended periods. Look for aprons that strike a balance between protection and comfort, offering lightweight designs and adjustable features for a customized fit.

Pockets and Storage: Welding aprons with pockets offer convenience and functionality. Look for aprons with multiple pockets of various sizes, allowing you to carry essential tools and small items close at hand. Additional features such as hanging loops or chest pockets enhance storage options and accessibility.

Best Leather Welding Apron Brands

Several reputable brands specialize in leather welding aprons, offering high-quality products that are designed to withstand the demands of welding environments. Here are a few top-rated brands worth considering:

Tillman: Tillman is a renowned brand in the welding industry and is known for its high-quality protective gear. Tillman welding aprons are made from durable, flame-resistant leather and provide excellent heat resistance and coverage. With features such as adjustable straps and reinforced stitching, Tillman aprons ensure optimal protection and durability.

Black Stallion: Black Stallion is committed to providing welders with reliable and functional welding aprons. Their aprons are made from high-quality leathers, offering dependable flame resistance and protection. Black Stallion aprons often feature unique designs, adjustable straps, and convenient storage solutions.

Lincoln Electric: Lincoln Electric is a trusted brand in welding equipment and safety gear. Their welding aprons are designed to meet the demands of professional welders, offering high-quality leathers, heat resistance, and durability. Lincoln Electric aprons are known for their craftsmanship and attention to detail.

By choosing welding aprons from these reputable brands, you can trust that you are investing in top-quality products that prioritize your safety and provide optimal protection for your upper body and lower limbs. Remember that wearing a leather welding apron is crucial for maintaining your safety and preventing potential injuries during welding operations.

Welding Safety Harnesses

Understanding the Need for Safety Harnesses

Safety harnesses are critical for the protection and fall prevention of welders working at heights or in elevated positions. They are an essential component of personal fall arrest systems (PFAS) and are designed to secure the wearer in the event of a fall, preventing serious injuries or fatalities.

Welding often involves tasks performed on scaffolds, elevated platforms, or other elevated structures. Without appropriate fall protection measures, welders are at risk of falling from heights and suffering severe injuries. Safety harnesses provide a secure anchorage point, distributing the forces of a fall throughout the body and reducing the risk of injury.

Factors to Consider When Buying a Welding Harness

Choosing the right welding harness requires careful consideration of several factors to ensure it meets industry safety standards and provides effective fall protection. Here are some key factors to consider:

Compliance: Ensure that the welding harness meets applicable safety standards and regulations, such as those set by the Occupational Safety and Health Administration (OSHA). Look for harnesses that are certified and labeled for specific applications, including welding at heights.

Construction and Durability: Welding harnesses should be constructed from high-quality, flame-resistant materials to withstand the rigors of welding environments. Look for harnesses made from materials such as nylon webbing or Kevlar, which offer excellent strength, durability, and resistance to heat and sparks.

Fit and Adjustability: A properly fitting harness is crucial for optimal safety and comfort. Look for harnesses with adjustable straps and buckles that allow for a secure and customized fit. Consider features such as padded straps and harness designs that prevent twisting or tangling.

Attachment Points: Check the number and location of attachment points on the harness. Attachment points are used to connect lanyards, lifelines, or other fall protection equipment. Ensure that the harness has sufficient attachment points for your specific welding tasks and working conditions.

Ease of Use and Maintenance: Consider how easy it is to put on and adjust the harness, as well as its maintenance requirements. Look for features such as quick-connect buckles or color-coded straps that facilitate ease of use. Regular inspection and maintenance of the harness are essential for ensuring its effectiveness, so choose a harness that allows for straightforward cleaning and maintenance procedures.

Top Welding Harness Manufacturers

Several reputable manufacturers specialize in welding safety harnesses. Here are a few top brands known for their quality and performance:

DBI-SALA: DBI-SALA, a brand under the 3M Fall Protection portfolio, offers a wide range of fall protection equipment, including welding harnesses. DBI-SALA harnesses are known for their durability, comfort, and reliability. They meet stringent safety standards and provide optimal protection for welders working at heights.

Miller by Honeywell: Miller by Honeywell is renowned for its comprehensive range of personal protective equipment, including welding harnesses. Their harnesses are designed with the comfort and safety of welders in mind, featuring adjustable straps, quality construction, and reliable fall arrest systems.

MSA Safety: MSA Safety is a trusted name in the safety industry, providing a variety of fall protection solutions. Their welding harnesses are designed to meet rigorous safety standards and offer excellent comfort and durability. MSA Safety harnesses often incorporate innovative features, such as automatic buckles or integrated rescue loops.

When purchasing a welding harness, consult with safety experts or professionals to ensure compliance with industry regulations and to select the harness that best suits your specific welding tasks and working conditions. Prioritizing fall protection is crucial for mitigating the risks associated with working at heights and ensuring the safety and well-being of welders.