If you’re a welding professional or simply someone who enjoys tackling welding projects as a hobby, then you know how important it is to protect your feet. The sparks, heat, and sharp objects involved in welding can pose serious risks to your feet. That’s where the best welding boots come in. In this article, we will explore the key features to look for in welding boots and provide you with valuable tips on how to choose the perfect pair that will keep your feet safe and comfortable throughout your welding endeavors. So, let’s get started on your journey to finding the best welding boots to protect your precious feet!

Understanding the Importance of Welding Boots

When it comes to the safety of welders, one crucial aspect that should not be overlooked is proper footwear. Welding boots play a significant role in ensuring your safety while you carry out welding tasks. Not only do they protect your feet from potential hazards, but they also provide comfort and support throughout your working day.

Role of Welding Boots in Your Safety

Welding boots are designed to provide a high level of protection against various hazards commonly encountered in a welding environment. By wearing the appropriate boots, you minimize the risk of injury and ensure a safer working experience.

Implications of Wearing Improper Footwear During Welding

Wearing improper footwear during welding can have serious consequences. When you expose yourself to potential hazards without the proper protection, you put yourself at risk of injury or even long-term damage. It is essential to understand the implications of wearing inadequate footwear and take the necessary precautions to ensure your safety.

Types of Hazards Welding Boots Protect Against

Protection against Sparks and Hot Metal

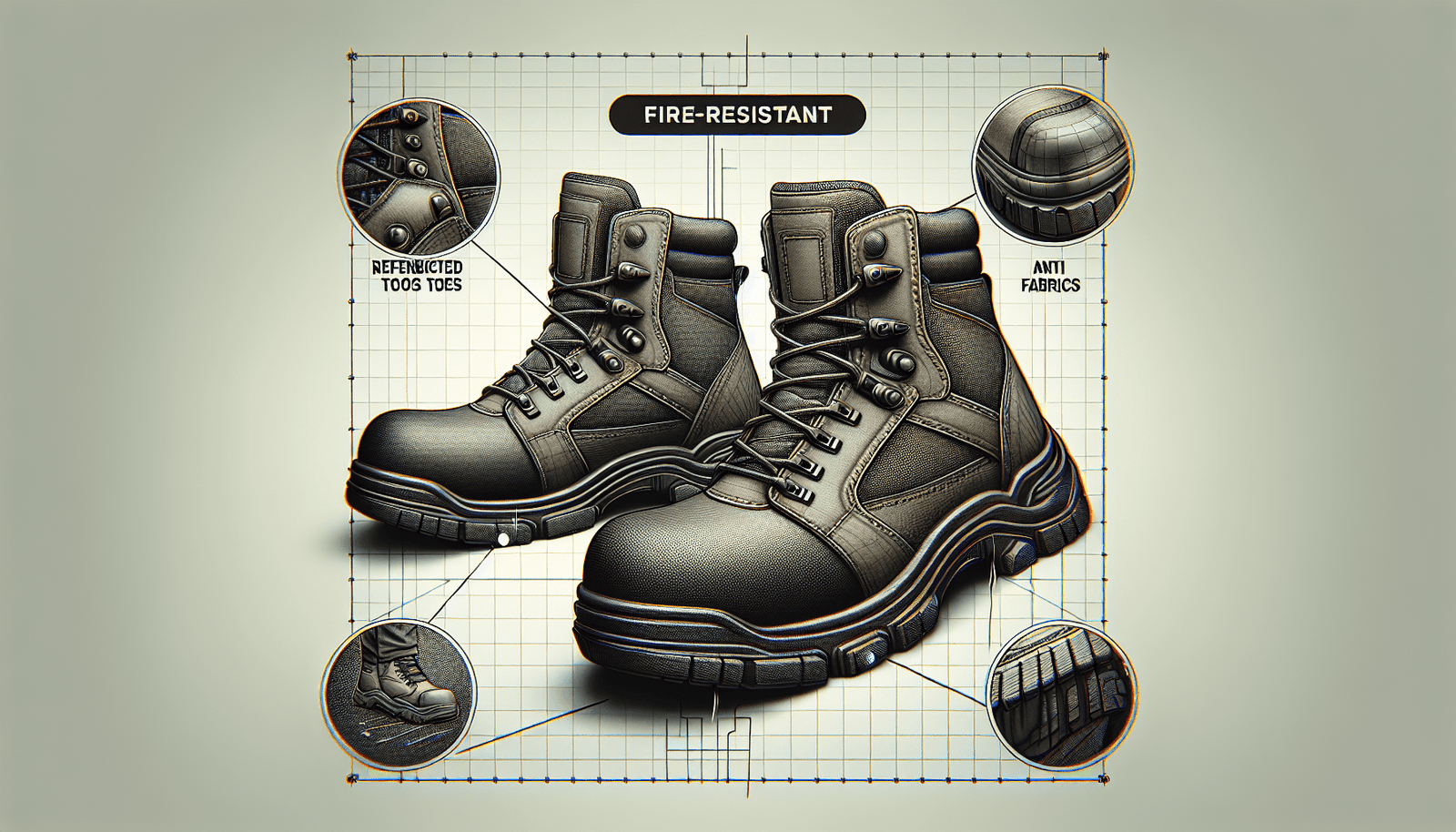

One of the primary hazards in welding is the potential for sparks and hot metal to land on your feet. Welding boots are specifically designed to have flame-resistant materials and construction, which helps protect against burns and other injuries caused by these sparks and hot materials.

Guard against Electric Shock

Welding involves working with electricity, which means there is a risk of electric shock if not adequately protected. Welding boots with electrical hazard (EH) rating provide insulation to guard against electric shock and ensure your safety in potentially dangerous situations.

Shield from Falling Objects

Welding environments often involve heavy machinery and equipment, which can pose a risk of falling objects. Welding boots with reinforced toes and sturdy construction offer protection against potential injuries caused by falling objects, ensuring your feet remain safe and secure.

Prevention of Slips and Falls

Another common hazard in welding shops is the possibility of slips and falls. The presence of oil, grease, or welding slag can make surfaces slippery, leading to accidents and injuries. Welding boots with slip-resistant outsoles provide the necessary traction and grip, reducing the likelihood of slips and falls, and helping maintain your balance on various types of surfaces.

Key Features to Look for in Welding Boots

Material Quality and Durability

When selecting welding boots, it is crucial to consider the quality and durability of the materials used. Look for boots made from high-quality leather or other flame-resistant materials that can withstand the rigors of welding tasks. Durable boots ensure they will last longer, providing you with ongoing protection and value.

Heat Resistant Outsole

The outsole of welding boots should be highly heat resistant to protect your feet from the dangers of extreme temperatures. Look for boots with outsoles made from materials such as rubber or thermoplastic polyurethane (TPU), as they offer excellent heat resistance properties.

Sufficient Cushioning and Comfort

Working long hours in a welding environment can take a toll on your feet. Therefore, it is essential to choose welding boots with sufficient cushioning and comfort features. Look for boots with padded insoles, arch support, and cushioned collars to ensure maximum comfort throughout your workday.

Shield from Electric Shock

As mentioned earlier, the risk of electric shock is present in welding environments. To protect yourself, select welding boots that have an electrical hazard (EH) rating, indicating they provide insulation against electric shock.

Quality of Laces or Closure System

The laces or closure system of your welding boots should be reliable and durable, ensuring a secure fit. Look for boots with strong laces or alternative closure mechanisms that will withstand the demands of your welding tasks and keep your boots snugly in place.

Considerations for Boot Height

The height of welding boots can also impact your safety. Higher boots offer increased protection, covering more of your leg and providing additional support. However, it is important to strike a balance between protection and comfort, considering your specific needs and preferences.

Understanding Safety Standards for Welding Boots

Importance of ASTM Certification

ASTM International, formerly known as the American Society for Testing and Materials, sets the standards for various safety products, including welding boots. When choosing welding boots, look for ASTM certification, which ensures that the boots have been tested and met safety standards specifically designed for welding.

Meaning of EH Rating

When you come across welding boots with an electrical hazard (EH) rating, it indicates that the boots provide a level of electrical shock protection. EH-rated boots are designed to protect you from accidental contact with electrical circuits or equipment, reducing the risk of electric shock.

Role of Slip Resistance in Safety Standards

Slips and falls can result in severe injuries, making slip resistance an essential safety feature in welding boots. Safety standards for welding boots often require slip-resistant outsoles, which offer increased traction and stability on various surfaces, minimizing the risk of accidents related to slipping.

Top Recommended Welding Boots Brands

Overview of Popular and Reliable Welding Boots Brands

Several brands stand out for their reliable and high-quality welding boots. These brands prioritize safety features, comfort, and durability, making them popular choices among welders. Some of the top recommended brands include Red Wing Shoes, Timberland PRO, Caterpillar, Dr. Martens, and Ariat.

Unique Features of Each Brand

Red Wing Shoes are well-known for their exceptional durability and craftsmanship. Timberland PRO offers a range of welding boots with innovative safety features and advanced technologies. Caterpillar is recognized for its robust and rugged boots designed to withstand harsh working conditions. Dr. Martens combines style with functionality, providing comfortable boots suitable for welding. Ariat offers a blend of performance and comfort, specializing in boots designed for workers in various industries, including welding.

Review of Specific Welding Boots Models

Key Features and Benefits of Selected Boots

To make an informed decision, it is crucial to review specific welding boots models that offer the necessary protection and comfort. Some popular models to consider are Red Wing Iron Ranger, Timberland PRO Men’s 6″ Pit Boss Soft Toe, Caterpillar Second Shift Steel Toe, Dr. Martens Ironbridge Steel Toe, and Ariat Men’s Groundbreaker Pull-On.

Understanding How Those Features Correlate to Protection

Each of these models incorporates various protective features to ensure your safety. These include flame-resistant materials, reinforced toes, slip-resistant outsoles, electrical hazard protection, and comfortable cushioning. By understanding how these features correlate to your protection needs, you can choose the boots that best suit your welding tasks.

The Role of Personal Comfort and Fit in Choosing Welding Boots

Understanding the Relation between Comfort, Fit, and Safety

When it comes to welding boots, comfort and fit play a vital role in ensuring both your safety and overall well-being. Ill-fitting boots can cause discomfort, distracting you from your task and potentially compromising your safety. Therefore, it is crucial to prioritize the comfort and fit of the boots you choose.

Proper Measurement and Sizing

To ensure a proper fit, it is important to accurately measure your feet and select the corresponding size. Different manufacturers may have slightly different size charts, so refer to the specific brand’s sizing guidelines for the most accurate measurements. Taking the time to measure your feet correctly will significantly contribute to finding boots that fit comfortably and securely.

Considerations for Pre-existing Foot Conditions

If you have pre-existing foot conditions such as bunions, flat feet, or plantar fasciitis, it is even more important to find welding boots that accommodate your specific needs. Look for boots that offer additional support, cushioning, or features that can alleviate any discomfort or potential aggravation of your condition.

Maintenance and Care of Welding Boots

Effective Cleaning Methods

Proper maintenance and regular cleaning of welding boots are essential to ensure their longevity and functionality. Start by removing any excess dirt or debris from the boots using a soft brush or cloth. For stubborn stains, use a mild soap or leather cleaner recommended by the manufacturer. Avoid soaking the boots in water and always allow them to air dry naturally.

Importance of Regular Maintenance

Regular maintenance is crucial to keep your welding boots in optimal condition. Check the boots regularly for any signs of damage or wear, such as worn outsoles, loose stitching, or cracked leather. Address any issues promptly to prevent further deterioration and ensure that your boots continue to provide the necessary protection and support.

Tips for Extending the Life of Your Boots

To extend the life of your welding boots, consider implementing a few simple practices. Avoid exposing them to excessive heat or direct sunlight for prolonged periods, as this can weaken the materials. Additionally, use appropriate leather conditioners or protective sprays recommended by the manufacturer to keep the leather moisturized and protected. Store the boots in a cool and well-ventilated area to prevent moisture buildup and maintain their integrity.

When to Replace Your Welding Boots

Identifying Signs of Wear and Tear

While welding boots are designed to be durable, they will eventually wear out over time. It is essential to identify signs of wear and tear to ensure optimal safety. Look out for visible cracks, holes, or significant sole wear. If you notice any of these signs, it is a clear indication that it is time to replace your welding boots.

Understanding the Average Lifespan of Welding Boots

The lifespan of welding boots can vary depending on factors such as frequency of use, working conditions, and maintenance. On average, welding boots can last anywhere from six months to a year or more, but it is crucial to assess their condition regularly and replace them as necessary to maintain the necessary level of protection.

Additional Protective Measures to Complement Welding Boots

Importance of Wearing Appropriate Welding Attire

While welding boots play a crucial role in foot protection, it is equally important to wear appropriate attire for overall safety. This includes flame-resistant clothing, such as welding jackets, pants, and gloves, to protect your body from sparks and heat generated during welding.

Role of Protective Goggles and Gloves

In addition to welding boots, protective goggles and gloves are essential to safeguard your eyes and hands, respectively. Welding goggles with appropriate shade levels shield your eyes from harmful UV radiation, while welding gloves provide heat resistance and dexterity for safe handling of materials and equipment.

Value of Investing in a Welding Helmet

A welding helmet is a crucial piece of protective gear that shields your face and neck from sparks, UV radiation, and heat during welding. Investing in a high-quality welding helmet with the appropriate shade level ensures optimal visibility and protection, enhancing your overall safety while working.

By understanding the importance of each of these additional protective measures and incorporating them alongside your welding boots, you can create a comprehensive safety strategy for a safer and more secure welding experience.

In conclusion, welding boots are an essential component of ensuring your safety in a welding environment. By understanding the hazards they protect against, key features to look for, safety standards, and recommended brands and models, you can make an informed decision when selecting welding boots. Additionally, considering personal comfort and fit, proper maintenance, and knowing when to replace your boots are essential for optimal safety. Finally, complementing your welding boots with appropriate welding attire, protective goggles and gloves, as well as a welding helmet, further enhances your overall safety and protection. Remember, prioritizing your safety today ensures a more secure and successful welding career in the future.