Are you a welding guru or someone looking for welding product reviews? If so, you may have some common questions about ductwork fabrication. In this article, we will address these common questions in a friendly and approachable tone, ensuring that the content is easy to understand and free from technical jargon. From the basics of ductwork fabrication to its importance in welding, we will provide concise answers to all your queries. Additionally, we will include a call to action at the end to encourage you to shop online. So, let’s dive into the world of ductwork fabrication and find answers to your burning questions.

Understanding Ductwork Fabrication

What is ductwork fabrication?

Ductwork fabrication is the process of creating custom ducts, which are used to transport air throughout a building’s HVAC (Heating, Ventilation, and Air Conditioning) system. It involves the design, measurement, cutting, joining, and sealing of various materials to create ducts that efficiently distribute air to different areas of a building.

Why is ductwork fabrication important?

Ductwork fabrication plays a crucial role in ensuring an efficient and effective HVAC system. Properly fabricated ductwork ensures that the conditioned air reaches its intended destinations without any leaks or obstructions. It helps in maintaining consistent indoor air quality, temperature control, and energy efficiency in both residential and commercial buildings.

What are the types of ductwork fabrication processes?

There are several types of ductwork fabrication processes, depending on the specific requirements and constraints of a project. Some common processes include:

Sheet Metal Fabrication: This involves cutting and shaping sheet metal, typically galvanized steel or aluminum, to create ducts of various shapes and sizes.

Fiberglass Duct Board Fabrication: Fiberglass duct board is a lightweight and flexible material used for fabricating ducts. It is cut into sections, folded, and sealed with adhesive to form ducts.

Flexible Duct Fabrication: Flexible ducts are made from a combination of materials such as plastic, wire coil, and insulation. They are easily bendable and are commonly used in applications where space is limited or irregularly shaped ducts are required.

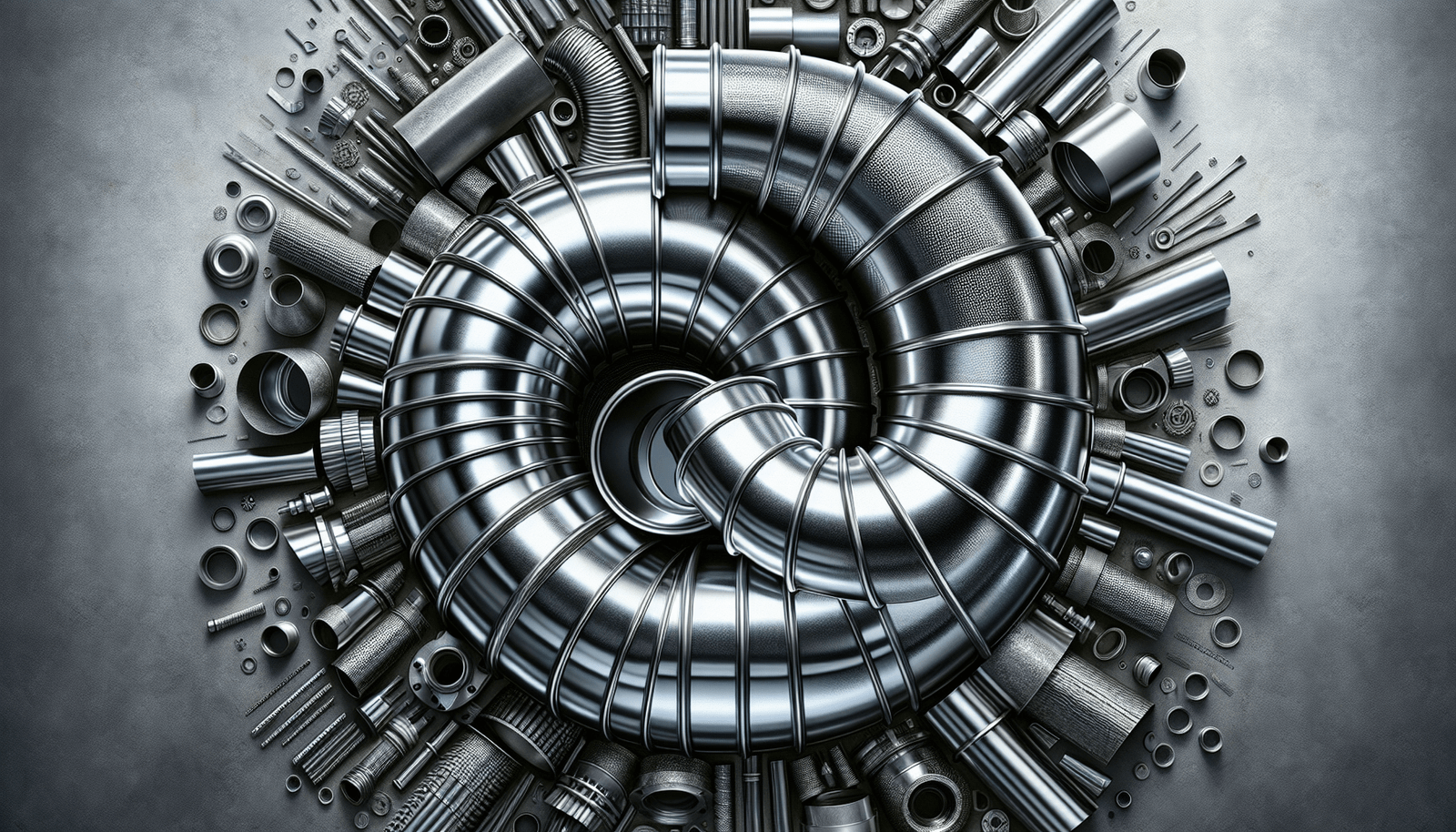

Spiral Duct Fabrication: Spiral ducts are created by forming a continuous spiral strip of metal, usually galvanized steel or aluminum, into a tubular shape. This process is most suitable for large-scale projects and provides high structural integrity.

Materials Used in Ductwork Fabrication

What materials are commonly used in ductwork fabrication?

The materials commonly used in ductwork fabrication include:

Sheet Metal: Galvanized steel and aluminum are popular choices for duct fabrication due to their durability, strength, and resistance to corrosion. They are widely available and offer good airflow properties.

Fiberglass Duct Board: Fiberglass duct board is lightweight, easy to work with, and provides good insulation properties. It is commonly used in residential applications where insulation is essential.

Flexible Materials: Flexible ducts are typically made from a combination of plastic, wire coil, and insulation materials. They offer flexibility and ease of installation in tight spaces or areas with irregular shapes.

How is material choice influenced by specific requirements?

The choice of materials for ductwork fabrication depends on various factors, including:

Environmental Conditions: The material selected must be able to withstand the environmental conditions it will be exposed to, such as extreme temperatures, humidity, or corrosive elements.

Airflow Requirements: Different materials have varying airflow properties, which can impact the overall efficiency and pressure drop of the HVAC system. The material choice should optimize airflow while minimizing resistance.

Insulation Needs: If thermal insulation is required, materials with good insulation properties, such as fiberglass duct board, may be preferred.

Can ductwork be fabricated from any materials other than metal?

Yes, apart from traditional sheet metal fabrication, ductwork can also be fabricated from other materials like fiberglass duct board, flexible materials, and even fabric composite materials. The choice of material depends on the specific requirements of the project and the desired attributes such as insulation, flexibility, or resistance to corrosion.

Tools and Machinery in Ductwork Fabrication

What tools are required in ductwork fabrication?

Various tools are used in ductwork fabrication to accurately cut, shape, join, and seal different materials. Some essential tools include:

Shears and Snips: These tools are used to cut sheet metal and fiberglass duct board with precision.

Hammers and Mallets: They are used to shape and form sheet metal into desired duct configurations.

Tape Measures and Rulers: Accurate measurements are crucial in ductwork fabrication, and these tools help ensure precise dimensions.

Nibblers and Seamers: Nibblers are employed in cutting irregular shapes, while seamers are used to join and bend sheet metal edges.

Adhesive and Sealants: Duct fabrication often requires the use of adhesive and sealants to securely join duct sections and make them airtight.

Which types of machinery are used for large-scale ductwork manufacturing?

For large-scale ductwork manufacturing, advanced machinery is employed to improve efficiency and accuracy. Some commonly used machinery includes:

CNC (Computer Numerical Control) Plasma Cutters: These machines use computer-guided cutting systems to accurately cut sheet metal into desired shapes and sizes.

Roll Forming Machines: Roll forming machines create seamless spiral ducts by continuously shaping a strip of metal into a tubular form. They provide high production rates and precise dimensions.

Powered Seamers: Powered seamers automate the process of joining and bending sheet metal edges, saving time and ensuring consistent results.

Laser Cutting Machines: Laser cutting machines are used to cut intricate designs and patterns in sheet metal for specialized ductwork requirements.

Safety considerations when using tools and machinery

When using tools and machinery in ductwork fabrication, it is essential to prioritize safety. Some important safety considerations include:

Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, and hearing protection, to protect against injuries.

Equipment Inspection: Regularly inspect tools and machinery for any defects or malfunctions before use.

Training and Education: Ensure that operators are properly trained and knowledgeable about the safe operation of tools and machinery.

Proper Ventilation: Adequate ventilation should be provided in the workspace to prevent the accumulation of dust, fumes, or other airborne particles.

Steps Involved in Ductwork Fabrication

What are the basic steps involved in fabricating a duct?

The basic steps involved in fabricating a duct are as follows:

Design and Measurement: Begin by determining the required dimensions, shape, and configuration of the duct. Accurate measurements are critical to ensure proper fit and functionality.

Material Selection and Cutting: Choose the appropriate material based on the specific requirements and cut it to the desired dimensions using tools such as shears or snips.

Shaping and Forming: If necessary, shape and form the duct material using hammers, mallets, or specialized tools to achieve the desired configuration.

Joining Sections: Use appropriate methods such as seamers, adhesives, or other connectors to join sections of the duct together securely.

Sealing and Insulation: Apply sealants or insulation materials to ensure the duct is airtight and meets insulation requirements.

How is accurate cutting of duct material ensured?

Accurate cutting of duct material is ensured through precise measurements and the use of appropriate cutting tools. Using a tape measure or ruler, mark the required dimensions on the material, and then cut along the marked lines using shears, snips, or other cutting tools. It is crucial to make precise cuts to ensure proper fit and functionality of the fabricated duct.

What methods are applied to join sections of ducts?

Various methods are applied to join sections of ducts, depending on the materials used and the requirements of the project. Some common methods include:

Locking and Folding: Sheet metal ducts can be joined by folding and locking the edges together, creating a secure connection.

Adhesive Bonding: Adhesives specially formulated for ductwork can be used to bond sections together. The adhesive creates a strong and airtight connection.

Mechanical Connectors: Clamps, fasteners, or connectors can be used to mechanically secure sections of the duct together.

Flex Duct Connectors: For flexible ducts, specially designed connectors with clamps or zip ties are used to connect sections seamlessly.

How are ducts made leak-proof?

To make ducts leak-proof, several measures can be taken during the fabrication process:

Proper Sealing: Apply appropriate sealant, such as duct sealant or foil tape, to seal joints and seams to prevent air leakage.

Mastic Application: Mastic is a specialized sealant that is applied to joints and seams to provide a durable, airtight seal.

Insulation: Insulating the ductwork can help maintain consistent temperatures, reduce condensation, and prevent air leakage.

Pressure Testing: Conduct pressure testing on the fabricated ducts to identify and address any potential leaks before installation.

Custom Ductwork Fabrication

When and why is custom ductwork fabrication needed?

Custom ductwork fabrication is needed when standard off-the-shelf ducts do not meet the specific requirements of a project. Custom fabrication allows for precise dimensions, shapes, and configurations to ensure optimal airflow distribution and compatibility with architectural constraints.

Custom ductwork may be necessary in situations such as:

Unique Building Designs: When a building has unconventional layouts or architectural features that require ducts to be tailored to fit specific spaces.

Retrofitting or Renovations: Existing buildings undergoing renovations or additions often require custom ductwork to integrate with the new HVAC systems while maintaining overall performance.

What criteria are used to design custom ducts?

Several criteria are considered when designing custom ducts, including:

Airflow Requirements: The design must account for the required airflow volume and velocity to ensure proper air distribution and comfort within the building.

Space Limitations: Custom ducts need to be designed to fit within the available space, considering architectural constraints and building layouts.

Noise Reduction: The duct design should minimize noise transmission by incorporating appropriate acoustic treatments and sound-dampening materials.

Energy Efficiency: Custom ductwork should be designed to minimize pressure drops, ensuring energy-efficient operation of the HVAC system.

Does custom ductwork fabrication demand additional costs?

Yes, custom ductwork fabrication generally incurs additional costs compared to using standard off-the-shelf ducts. The additional costs are primarily due to the need for specialized design, labor, and materials to meet the specific requirements of the project. However, the benefits of custom ductwork, such as improved performance, energy efficiency, and optimized airflow distribution, often outweigh the additional expenses.

Quality and Standards in Ductwork Fabrication

What quality standards apply to ductwork fabrication?

Ductwork fabrication is subject to various quality standards, which may vary depending on the region or industry. Some common quality standards include:

SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association): SMACNA provides guidelines and standards for the fabrication and installation of HVAC systems, including ductwork.

ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers): ASHRAE publishes standards and guidelines related to energy efficiency, indoor air quality, and HVAC system design and performance.

UL (Underwriters Laboratories): UL provides certification and testing services for HVAC products, including ductwork, ensuring they meet safety and performance standards.

How is quality testing conducted?

Quality testing in ductwork fabrication may involve various procedures, including:

Air Leakage Testing: Ductwork is tested for air leaks using methods such as pressure testing or smoke testing to ensure the ducts are airtight.

Dimensional Inspections: Ducts are inspected for accurate dimensions and proper fit to ensure they meet the design specifications.

Material Performance Testing: Materials used in duct fabrication may undergo testing to assess their mechanical strength, corrosion resistance, and durability.

Compliance Verification: Fabricated ductwork may undergo inspections and audits to verify compliance with relevant standards and regulations.

Why does ductwork need to comply with certain standards?

Compliance with quality standards is essential in ductwork fabrication for several reasons:

Health and Safety: Ductwork that is improperly fabricated, installed, or maintained can pose health and safety risks, such as poor indoor air quality, mold growth, or fire hazards. Compliance with standards helps mitigate these risks.

Performance and Efficiency: Ductwork that meets quality standards ensures optimal performance and energy efficiency of the HVAC system, leading to improved comfort and reduced energy consumption.

Legal Requirements: Certain jurisdictions may have codes and regulations that dictate the quality and performance standards for ductwork fabrication. Compliance with these requirements is necessary to avoid legal issues or penalties.

Maintaining Fabricated Ductwork

What routine maintenance is necessary for fabricated ductwork?

Routine maintenance is essential to ensure the longevity and optimal performance of fabricated ductwork. Some key maintenance tasks include:

Regular Cleaning: Ducts should be cleaned periodically to remove dust, debris, and contaminants that can accumulate over time and compromise airflow and indoor air quality.

Insulation Inspection: Insulated ductwork should be inspected for any damage or degradation of the insulation material, and repairs or replacements should be done as necessary.

Sealant Inspection and Reapplication: Check the integrity of sealants used in duct joints and seams and reapply as needed to maintain air tightness.

Airflow Testing: Conduct periodic airflow testing to identify any obstructions, leaks, or reduced airflow, addressing them promptly to maintain optimal system performance.

How often should fabricated ductwork be checked for faults or damage?

Fabricated ductwork should be checked for faults or damage periodically. The frequency of inspections may vary depending on factors such as the age of the ductwork, environmental conditions, and the HVAC system’s usage. As a general guideline, a comprehensive inspection every 3-5 years is recommended, supplemented by regular visual assessments for signs of deterioration.

What are the signs of deteriorating ductwork?

Signs of deteriorating ductwork include:

Visible Leaks or Damage: Any visible gaps, cracks, or holes in the ductwork indicate damage or wear and tear that can compromise performance and efficiency.

Increased Energy Consumption: A sudden spike in energy consumption without any changes in usage patterns can be an indication of ductwork problems, such as leaks.

Uneven Temperature Distribution: If certain areas of a building experience uneven cooling or heating, it may be a sign of ductwork damage or improper airflow distribution.

Poor Air Quality or Allergies: Deteriorating ductwork can allow contaminants to enter the air supply, leading to poor indoor air quality, unpleasant odors, or increased allergic reactions.

Environmental Impact of Ductwork Fabrication

How does ductwork fabrication affect the environment?

Ductwork fabrication can have both positive and negative environmental impacts. The primary environmental considerations include:

Energy Efficiency: Properly designed and fabricated ductwork contributes to energy efficiency by minimizing air leakage and pressure drops, resulting in reduced energy consumption and carbon emissions.

Material Selection: The choice of materials for ductwork fabrication can have environmental implications. Opting for sustainable materials, such as recycled metal or bio-based insulation, can help reduce the carbon footprint.

Waste Generation: Ductwork fabrication generates waste material, primarily in the form of cutoffs and scrap. Proper waste management practices, such as recycling or reuse, can minimize the environmental impact.

What steps are taken to minimize the environmental impact during ductwork fabrication?

To minimize the environmental impact during ductwork fabrication, several measures can be taken, including:

Energy-Efficient Design: Implementing energy-efficient design strategies, such as optimizing airflow and minimizing pressure drops, can reduce energy consumption and associated environmental impacts.

Material Selection: Choosing environmentally friendly materials, such as recycled metal or low VOC (Volatile Organic Compound) insulation, supports sustainable practices and reduces environmental harm.

Waste Management: Establishing effective waste management practices, including recycling or proper disposal of waste materials, helps minimize the environmental impact of ductwork fabrication.

Green Certifications: Seeking green certifications, such as LEED (Leadership in Energy and Environmental Design), promotes sustainable practices and ensures compliance with environmental standards.

Cost Considerations in Ductwork Fabrication

What factors influence the cost of ductwork fabrication?

Several factors influence the cost of ductwork fabrication, including:

Size and Complexity: Larger or more complex ductwork designs require additional materials, labor, and potentially specialized equipment, resulting in higher fabrication costs.

Material Choice: Different materials have different costs, with sheet metal generally being more cost-effective compared to specialized materials like fiberglass duct board or flexible ducts.

Customization: Custom ductwork fabrication often involves additional design, labor, and material expenses compared to using standardized ducts.

Location and Accessibility: Factors such as the location of the project site, site accessibility, and transportation costs can affect the overall fabrication costs.

How can consumers estimate their ductwork fabrication costs?

To estimate ductwork fabrication costs, consumers can consider the following steps:

Consultation and Design: Work with a reputable ductwork fabricator to discuss project requirements and obtain a design and cost estimate based on specific needs.

Material Selection: Determine the desired materials for duct fabrication and gather cost estimates from suppliers or fabricators.

Labor and Installation: Discuss labor and installation costs with the fabricator, considering factors such as project complexity and timeline.

Additional Expenses: Consider any additional expenses related to customization, specialized equipment, or any unique project requirements.

Request Multiple Quotes: Obtain quotes from multiple fabricators to compare costs and ensure competitive pricing.

How can cost efficiency be maximized in ductwork fabrication?

To maximize cost efficiency in ductwork fabrication, consider the following strategies:

Optimize Design: Work closely with the fabricator to optimize the design for airflow efficiency, material usage, and ease of installation, minimizing unnecessary costs.

Evaluate Material Options: Balance the cost and performance characteristics of different materials to select the most suitable and cost-effective options.

Standardize Where Possible: Utilize standardized duct sizes and configurations whenever feasible to reduce customization costs.

Seek Professional Advice: Consult with experienced ductwork professionals who can provide guidance on cost-saving measures and value engineering.

Finding a Reliable Ductwork Fabricator

What qualifications should a professional ductwork fabricator have?

A professional ductwork fabricator should possess the following qualifications:

Experience and Expertise: Look for fabricators with a solid track record and extensive experience in ductwork fabrication, with a focus on delivering high-quality products.

Certification and Compliance: Ensure the fabricator complies with relevant industry standards and possesses necessary certifications or accreditations, such as SMACNA or UL certifications.

Knowledge of Regulations: The fabricator should have a thorough understanding of local building codes, regulations, and industry best practices to ensure compliance in all aspects of ductwork fabrication.

Skilled Workforce: Verify that the fabricator employs skilled and trained personnel who can deliver precision fabrication work.

What questions should be asked when hiring a fabricator?

When hiring a ductwork fabricator, it is important to ask the following questions:

Are you licensed and insured?

How long have you been in the ductwork fabrication business?

Can you provide references from previous clients or projects?

What certifications or standards do you adhere to in your fabrication processes?

Do you have experience working with the specific materials and designs required for the project?

What is your estimated timeline for completing the fabrication work?

Can you provide a detailed cost breakdown, including material, labor, and any additional expenses?

What are some red flags or warning signs to look out for when selecting a ductwork fabricator?

When selecting a ductwork fabricator, be cautious of the following red flags or warning signs:

Lack of Experience or Reputation: Fabricators with little experience or a poor reputation may not deliver the desired quality or meet project requirements.

Unverifiable Claims: Be skeptical of fabricators who make unsubstantiated claims or hesitate to provide references or examples of their previous work.

Poor Communication: Communication gaps or difficulties in obtaining timely and clear responses to queries may indicate potential issues with the fabricator’s reliability and professionalism.

Unreasonable Low Pricing: Unrealistically low pricing may indicate the use of subpar materials, poor workmanship, or hidden costs that may arise later in the project.

Noncompliance with Standards or Regulations: Fabricators who cannot provide evidence of compliance with relevant industry standards and regulations should be approached with caution, as this could lead to future complications.

By considering these factors and conducting thorough research, you can find a reliable ductwork fabricator capable of delivering high-quality products and services. Remember to seek multiple quotes, review credentials, and verify references before making a final decision.