When it comes to welding, proper electrode storage is crucial to ensure optimal performance. But with so many options available, how do you choose the best welding electrode ovens? In this article, we will guide you through the process of selecting the right ovens for your welding electrodes. From understanding the importance of temperature control to considering the size and capacity of the oven, we will provide you with the necessary information to make an informed decision. So, let’s dive in and explore the world of welding electrode ovens together!

Understanding the Importance of Welding Electrode Ovens

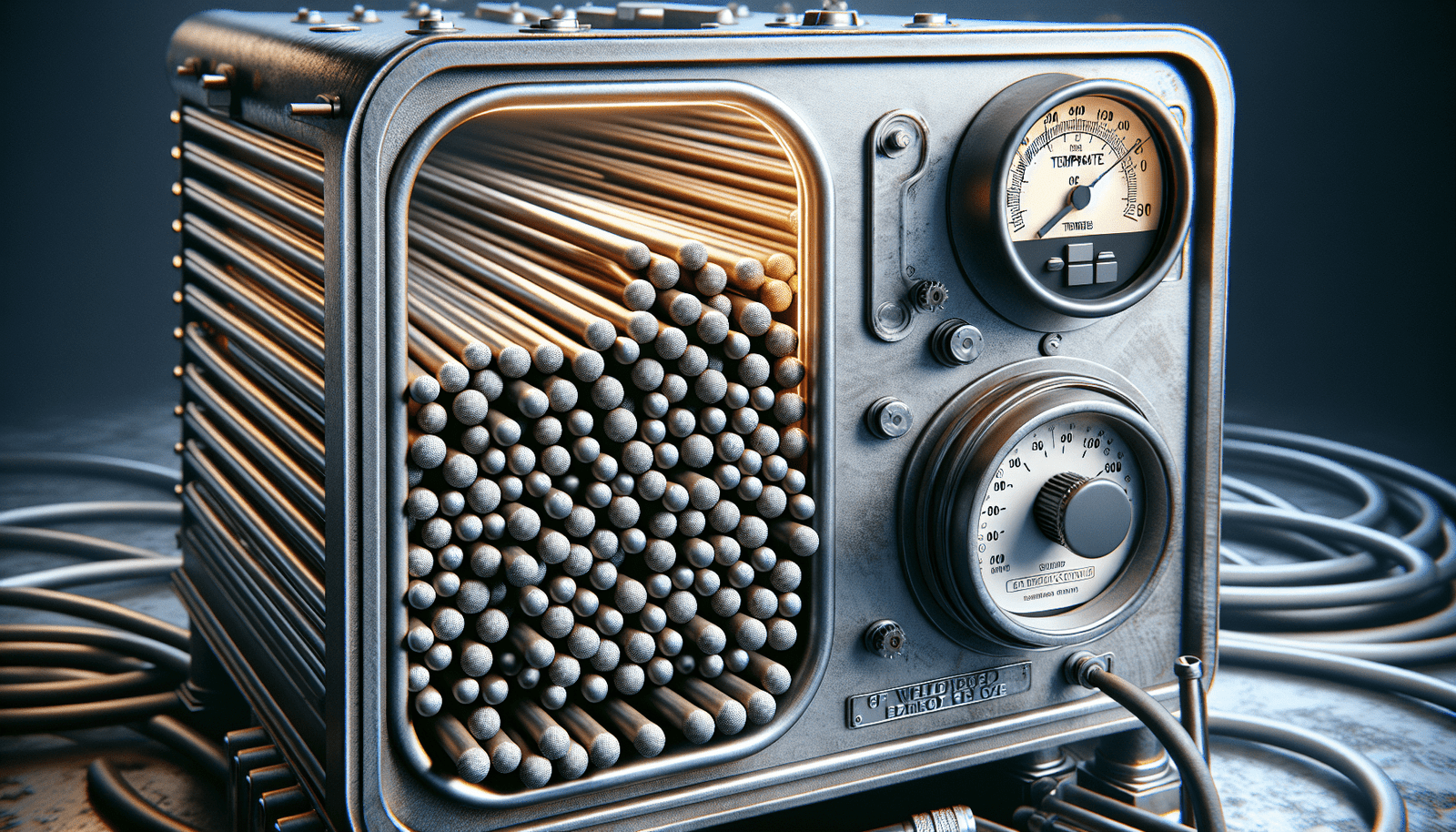

The role of welding electrode ovens

When it comes to welding, the quality of the welding electrode plays a crucial role in the strength and durability of the weld. Welding electrode ovens are specifically designed to store and maintain the quality of these electrodes. The main role of welding electrode ovens is to keep the electrodes dry and at the optimal temperature, which prevents moisture absorption and ensures consistent performance.

Reasons for properly storing electrodes

Properly storing electrodes is essential for maintaining their quality and effectiveness. Welding electrodes are sensitive to moisture, and even a small amount of moisture can negatively impact their performance. Adequate storage in electrode ovens helps to prevent moisture absorption, minimizing the risk of porosity, cracking, or weakened welds. Additionally, proper storage extends the shelf life of electrodes, ensuring they remain in optimal condition and ready for use when needed.

Impacts of moisture on welding electrodes

Moisture is one of the biggest enemies when it comes to welding electrodes. When electrodes are exposed to moisture, they can become contaminated, leading to various welding defects. Moisture absorbed by the electrodes can cause instability in the arc, resulting in poor penetration and inconsistent weld quality. It can also lead to porosity, hydrogen cracking, and reduced strength in the weld joint. Using welding electrode ovens to store the electrodes properly helps to eliminate these issues and ensures reliable and high-quality welds.

Achieving optimum performance with good electrode storage

Proper storage of welding electrodes in electrode ovens directly contributes to achieving optimum performance in welding operations. When electrodes are stored in an environment with controlled temperature and low humidity, their quality remains intact. This allows for a consistent arc, improved weld bead appearance, and better penetration. Good electrode storage ultimately leads to increased productivity, reduced rework, and improved weld quality, enabling you to deliver excellent results in your welding projects.

Types of Welding Electrode Ovens

Portable welding electrode ovens

Portable welding electrode ovens are compact and lightweight, making them easily transportable to different job sites. They are typically designed to hold a small number of electrodes and are suitable for individual or mobile welding operations. These ovens provide basic temperature control and are an excellent choice for welders who frequently move between locations.

Bench welding electrode ovens

Bench welding electrode ovens are larger than portable ovens and are designed to sit on a workbench or table. They can hold a larger quantity of electrodes and provide more precise temperature control. Bench ovens are commonly used in workshops or smaller welding operations where portability is not a primary concern. They offer convenience and ease of use, allowing welders to have easy access to their electrodes during welding processes.

Industrial welding electrode ovens

Industrial welding electrode ovens are larger, heavy-duty ovens that are built for high-capacity electrode storage. They are typically used in industrial settings or large-scale welding operations where a significant number of electrodes are required. Industrial ovens often feature advanced temperature control systems, durable construction, and additional safety features to meet the demands of heavy usage. These ovens ensure optimum storage conditions for a large quantity of electrodes, enabling efficient and uninterrupted welding operations.

Characteristics and uses of each type

Each type of welding electrode oven has its own unique characteristics and is suitable for different purposes. Portable ovens are ideal for welders who frequently work in different locations and need to transport their electrodes easily. Bench ovens provide more capacity and temperature control, making them suitable for smaller workshops or ongoing projects. Industrial ovens are designed for high-capacity electrode storage and are well-suited for industrial settings where large quantities of electrodes are required.

Key Features to Consider in a Welding Electrode Oven

Temperature range of the oven

The temperature range of a welding electrode oven is a critical factor to consider. Different types of electrodes require different temperature ranges for optimal storage. It is important to choose an oven that offers a temperature range suitable for the electrodes you use. Look for an oven that allows you to easily adjust and control the temperature to meet the specific requirements of your welding operations.

Capacity of the oven

Consider the capacity of the oven in terms of the number of electrodes it can store. The capacity you need depends on the volume of welding work you typically handle and the size of the electrodes you use. Ensure that the oven you choose has adequate capacity to meet your needs and allows for efficient organization and storage of your electrodes.

Temperature control accuracy

Temperature control accuracy is crucial for maintaining the quality of welding electrodes. Look for an oven that offers precise temperature control, allowing you to set and maintain the desired temperature consistently. A reliable temperature control system ensures that the electrodes are stored at the optimal temperature, eliminating the risk of moisture absorption and preserving their performance.

Durability and build quality of the oven

Considering the durability and build quality of the welding electrode oven is essential to ensure its longevity and reliable performance. Look for ovens made from high-quality materials that can withstand the demands of welding environments. A sturdy and well-built oven will be able to endure frequent usage, resist corrosion, and offer protection to your electrodes. Additionally, check if the oven has proper insulation to minimize heat loss and improve energy efficiency.

Reviewing Top Welding Electrode Oven Brands

Phoenix electrode ovens

Phoenix is a well-known brand in the welding industry and offers a range of reliable and high-performing electrode ovens. Their ovens are designed with advanced temperature control systems and durable construction. Phoenix electrode ovens are available in various sizes to accommodate different capacities and offer precise temperature control for maintaining electrode quality.

Keen Ovens

Keen Ovens is another reputable brand that specializes in welding electrode storage solutions. Their ovens are known for their durability and excellent temperature control accuracy. Keen Ovens offer a range of sizes and capacity options to suit different welding needs. They also prioritize safety features in their oven designs to ensure the well-being of users and the protection of electrodes.

Arcair electrode ovens

Arcair is a trusted brand that offers a wide range of welding products, including electrode ovens. Arcair electrode ovens are designed to provide reliable and consistent temperature control, ensuring optimum electrode storage conditions. They offer different models with varying capacities and features, allowing welders to choose the one that best suits their requirements.

Comparing features and pricing for these brands

When selecting a welding electrode oven, it is essential to compare the features and pricing offered by different brands. Consider factors such as temperature control accuracy, capacity, construction quality, and safety features. Additionally, compare the prices of the ovens to ensure that you are getting the best value for your money. By carefully evaluating the features and pricing of different brands, you can make an informed decision and choose the welding electrode oven that meets your specific needs.

Understanding the Costs Associated with Welding Electrode Ovens

Typical price range for welding electrode ovens

The price range for welding electrode ovens can vary depending on the brand, size, and features of the oven. Portable ovens typically range from $100 to $300, while bench ovens can range from $300 to $700. Industrial ovens, with their larger capacity and advanced features, can range from $1000 to $3000 or more. It is important to consider your budget and the specific requirements of your welding operations when determining the appropriate price range for your welding electrode oven.

Influencing factors on the price of an oven

Several factors can influence the price of a welding electrode oven. The size and capacity of the oven, as well as the materials used in its construction, can affect the overall cost. Ovens with advanced temperature control systems and additional safety features may have a higher price tag. The reputation and brand value of the manufacturer can also contribute to the price. Additionally, the level of precision and quality in the oven’s temperature control system can impact the cost. Consider these factors when evaluating the price of a welding electrode oven.

Cost-effectiveness comparison of various oven models

While the initial cost of a welding electrode oven is an important consideration, it is also crucial to evaluate its long-term cost-effectiveness. A cost-effective oven not only meets your budget but also provides reliable performance, durability, and energy efficiency. Consider factors such as energy consumption, insulation quality, and maintenance requirements when determining the long-term cost-effectiveness of an oven. Investing in a high-quality oven that offers optimal electrode storage conditions can save you money in the long run by minimizing electrode wastage and improving overall welding efficiency.

Installation and Maintenance of Welding Electrode Ovens

Setting up a welding electrode oven

Setting up a welding electrode oven is a relatively straightforward process. Start by choosing a suitable location for the oven, ensuring it is away from any flammable or combustible materials. Connect the oven to a power source, following the manufacturer’s instructions and safety guidelines. Once the oven is properly connected, set the desired temperature based on the electrode manufacturer’s recommendations. Allow the oven to reach the set temperature before placing the electrodes inside. Periodically check the temperature and adjust it as necessary throughout the welding process.

Routine maintenance recommendations

To ensure the longevity and functionality of a welding electrode oven, regular maintenance is necessary. Here are some routine maintenance recommendations:

Keep the oven clean: Regularly clean the interior of the oven to remove any debris, dust, or residue that may affect its performance. Use a soft cloth or brush to clean the electrodes and the oven’s interior.

Check and replace gaskets: Inspect the oven’s gaskets regularly and replace them as needed. Damaged or worn gaskets can allow heat and moisture to escape, compromising the oven’s performance.

Monitor temperature accuracy: Periodically check the temperature accuracy of the oven using a reliable thermometer. If any discrepancies are observed, arrange for necessary adjustments or repairs.

Check electrical connections: Inspect the electrical connections and power cord for any signs of damage or wear. Loose or damaged connections should be repaired or replaced promptly to ensure safety.

Calibrate temperature controls: If your oven has adjustable temperature controls, consider calibrating them periodically to ensure accurate temperature settings. Consult the manufacturer’s guidelines for calibration procedures.

Common problems and solutions for electrode ovens

Like any equipment, welding electrode ovens can encounter issues during their lifespan. Here are some common problems and their solutions:

Inconsistent temperature: If the oven’s temperature is inconsistent, check if the heating element is functioning correctly. The heating element may need to be replaced if it is damaged. Ensure that the oven is properly insulated to minimize heat loss.

Moisture leakage: If you notice moisture leakage inside the oven, check the gaskets and seals for any damage or wear. Replace them if necessary. Ensure that the oven is properly closed and sealed to prevent moisture ingress.

Power supply issues: If the oven does not turn on or experiences power supply issues, check the electrical connections, power cord, and fuse or circuit breaker. Repair or replace any damaged components as needed.

Temperature control problems: If the temperature control is not functioning properly, check if the thermostat or temperature sensor is working correctly. Contact the manufacturer or a professional technician for repairs or replacements.

Remember to always refer to the manufacturer’s guidelines and seek professional assistance if you encounter any complex issues with your welding electrode oven.

Safety Precautions When Using Welding Electrode Ovens

Proper handling of the electrode oven

Safety should always be a top priority when using a welding electrode oven. Here are some key safety precautions to follow:

Read the manufacturer’s instructions: Familiarize yourself with the manufacturer’s instructions and guidelines for operating the electrode oven. Follow these guidelines meticulously for safe and efficient use.

Ensure proper ventilation: Use the electrode oven in a well-ventilated area to prevent the accumulation of harmful gases or fumes. Good ventilation helps maintain a safe working environment.

Use personal protective equipment (PPE): Wear appropriate PPE, including gloves, safety glasses, and heat-resistant clothing, when handling the electrode oven. This protects you from burns or injuries during the loading and unloading process.

Avoid overcrowding: Do not overcrowd the oven with electrodes. Ensure there is enough space between the electrodes for proper airflow and heat distribution.

Do not touch hot surfaces: Always use oven mitts or heat-resistant gloves when handling hot oven surfaces or trays. Avoid touching hot surfaces with bare hands to prevent burns.

Safety equipment and protocols for using an oven

In addition to following proper handling practices, using appropriate safety equipment and following safety protocols is essential when using an electrode oven. Consider the following safety measures:

Fire safety: Keep a fire extinguisher nearby in case of any electrical malfunctions or fires. Ensure that you have a clear evacuation plan and that everyone present is aware of emergency exits.

Eye protection: Wear safety glasses or a welding helmet with a suitable lens shade to protect your eyes from harmful rays emitted by the welding process.

Heat-resistant surfaces: Place the oven on a heat-resistant surface or use a protective mat to prevent heat damage to surrounding materials.

Adequate lighting: Ensure that the area around the electrode oven is well-lit to avoid accidents or injuries.

Electrical safety: Only plug the oven into grounded outlets and ensure that the power source can handle the oven’s electrical requirements. Avoid using extension cords unless absolutely necessary.

Dealing with common safety hazards

To minimize the risk of safety hazards, it is important to be aware of and address common issues that may arise when using an electrode oven. Here are some common safety hazards and their solutions:

Electrical hazards: Inspect the power cords and electrical connections for any signs of damage or wear. Replace any damaged components and ensure proper grounding to minimize the risk of electrical hazards.

Fire hazards: Keep the oven away from flammable materials and ensure that it is not overloaded with electrodes. Properly ventilate the area to prevent the build-up of flammable gases or fumes.

Burns and injuries: Always use heat-resistant gloves or oven mitts when handling hot surfaces or trays. Avoid coming into contact with hot surfaces to prevent burns.

Temperature-related injuries: Be cautious of hot surfaces or trays when unloading electrodes from the oven. Ensure that the oven has cooled down sufficiently before handling the electrodes.

Inhalation of fumes: Use the electrode oven in a well-ventilated area to minimize the inhalation of harmful gases or fumes. Consider using additional exhaust or ventilation systems if necessary.

By following these safety precautions and addressing potential hazards, you can ensure a safe working environment and minimize the risk of accidents or injuries when using a welding electrode oven.

Training and Qualifications for Proper Oven Use and Maintenance

Necessary skills for welding oven use

Using a welding electrode oven requires certain skills and knowledge to ensure its proper use and maintenance. Some of the necessary skills include:

Understanding electrode types: Familiarize yourself with different types of electrodes and their respective storage requirements. This knowledge helps in selecting the appropriate oven temperature and storage conditions.

Temperature control: Gain an understanding of temperature control systems and how to adjust them accurately. This skill ensures the maintenance of optimal storage conditions for electrodes.

Loading and unloading procedures: Learn the correct procedures for loading and unloading electrodes from the oven. Proper handling minimizes the risk of injuries and maintains electrode quality.

Routine maintenance: Acquire the skills necessary for routine maintenance of the oven. This includes cleaning, inspecting and replacing gaskets, calibrating temperature controls, and other basic maintenance tasks.

Training programs for welding oven operators

To enhance your skills and knowledge in welding electrode oven use, consider participating in training programs or courses specifically designed for welding professionals. These programs provide comprehensive training on various aspects of welding, including electrode storage and oven use. They offer practical guidance, safety protocols, and hands-on experience to ensure operators can confidently handle electrode ovens and perform routine maintenance effectively. Look for reputable training institutions or welding organizations that offer certification programs or workshops focused on electrode oven operations.

Benefits of receiving professional training

Receiving professional training in welding oven use offers several benefits:

Enhanced safety: Proper training helps operators understand and follow safety protocols, minimizing the risk of accidents or injuries during electrode oven use.

Improved efficiency: Training enables operators to use the electrode oven correctly, ensuring optimal electrode storage conditions and maximizing welding efficiency.

Extended equipment lifespan: By knowing how to operate, maintain, and troubleshoot the oven properly, operators can extend its lifespan and reduce the need for expensive repairs or replacements.

Compliance with industry standards: Professional training ensures compliance with industry standards and best practices, enhancing the quality of welding operations and meeting customer expectations.

Investing in professional training for welding electrode oven use not only benefits individual operators but also contributes to the overall success and productivity of welding operations.

Environmental Consideration for Welding Electrode Ovens

How to choose energy-efficient electrode ovens

Choosing energy-efficient electrode ovens is important to minimize environmental impact and reduce energy consumption. Consider the following factors when selecting an energy-efficient oven:

Insulation quality: Look for ovens with high-quality insulation to minimize heat loss. Well-insulated ovens require less energy to reach and maintain the desired temperature.

Energy-saving features: Some electrode ovens offer energy-saving features such as programmable timers or sleep mode to reduce energy consumption during periods of inactivity.

Temperature control accuracy: Opt for ovens with precise temperature control to prevent unnecessary energy usage. Accurate temperature control ensures that the oven maintains the desired temperature without excessive fluctuations.

Energy-efficient construction materials: Consider ovens made from energy-efficient materials that retain heat effectively and require less energy to operate.

By selecting energy-efficient electrode ovens, you not only reduce your environmental footprint but also lower operating costs in the long run.

Sustainable practices in electrode storage

Implementing sustainable practices in electrode storage can further reduce environmental impact. Here are some sustainable practices to consider:

Use reusable storage containers: Instead of relying on disposable packaging for electrodes, opt for reusable storage containers. This reduces waste and promotes sustainability.

Proper waste disposal: Dispose of electrode packaging and waste materials responsibly. Follow local regulations for recycling or disposal of packaging and other waste materials.

Optimize electrode usage: Minimize electrode wastage by accurately assessing the number of electrodes required for each project. Avoid overstocking to reduce unnecessary material consumption.

Recycling programs: Investigate recycling programs offered by manufacturers or local recycling centers for proper disposal of used or damaged electrodes.

By adopting sustainable practices in electrode storage, you contribute to environmental conservation while maintaining efficient and quality welding operations.

Environmental impacts and safety regulations

It is important to be aware of the potential environmental impacts associated with welding electrode ovens and comply with safety regulations. Some environmental impacts include:

Energy consumption: Welding electrode ovens consume energy during their operation. By choosing energy-efficient models and optimizing energy usage, you can minimize the environmental impact of energy consumption.

Emissions: The welding process itself can generate emissions and harmful gases. Proper ventilation and exhaust systems are crucial in minimizing the release of these emissions and ensuring a safe working environment.

Hazardous materials: Some components of welding electrodes or their packaging may be considered hazardous waste. It is essential to handle and dispose of these materials properly to comply with environmental regulations.

Environmental regulations: Familiarize yourself with relevant environmental regulations and guidelines pertaining to electrode storage and disposal in your local area. Adhering to these regulations helps protect the environment and ensures compliance with legal requirements.

By understanding and complying with environmental regulations, you can contribute to a healthier and more sustainable environment while ensuring the safe operation of welding electrode ovens.

Final Tips for Choosing the Best Welding Electrode Oven

Recap of key factors to consider

When choosing the best welding electrode oven for your needs, consider the following key factors:

- Temperature range suitable for the electrode types you use.

- Capacity to accommodate your electrode storage requirements.

- Temperature control accuracy for maintaining optimal storage conditions.

- Durability and build quality to withstand demanding welding environments.

By evaluating these factors, you can select an oven that meets your unique welding requirements while ensuring the longevity and performance of your electrodes.

Getting expert advice and reading product reviews

Seeking expert advice and reading product reviews can provide valuable insights into the performance and reliability of different welding electrode oven brands and models. Consult experienced welders or industry professionals who have firsthand knowledge of various oven brands. Online forums and welding communities can be excellent sources of information and recommendations. Additionally, reading product reviews from reliable sources can provide you with insights into the experiences of other users and help you make an informed decision.

Balancing cost, performance, and safety in your final decision

When making your final decision on which welding electrode oven to purchase, it is essential to strike a balance between cost, performance, and safety. Consider your budget limitations while ensuring that the chosen oven meets your performance requirements. Remember to prioritize safety features and adherence to safety standards, as the safety of the oven and its operation are vital for both the welder and the electrode quality. By carefully weighing these factors, you can choose the best welding electrode oven that provides optimal electrode storage and enhances your welding processes.

In conclusion, welding electrode ovens play a crucial role in maintaining the quality and performance of welding electrodes. Proper storage in these ovens prevents moisture absorption, ensures consistent performance, and reduces the risk of welding defects. Understanding the different types of welding electrode ovens, key features to consider, and the costs and maintenance associated with these ovens is essential for making an informed decision. By prioritizing safety, receiving proper training, and considering environmental impacts, you can select the best welding electrode oven that meets your needs while promoting efficient, high-quality, and sustainable welding operations.