If you’re a welding enthusiast or a professional in the field, you understand the importance of precision when it comes to tungsten sharpening. Getting that perfect edge is crucial for achieving high-quality welds. That’s why we’re here to provide you with a comprehensive guide on the best welding tungsten grinders available in the market. From their features and benefits to their ease of use and durability, we’ve got you covered. So, whether you’re a seasoned welder or just starting out, read on to discover the perfect tungsten grinder that will help you achieve precise and flawless results every time.

Understanding the Importance of Tungsten Grinder in Welding

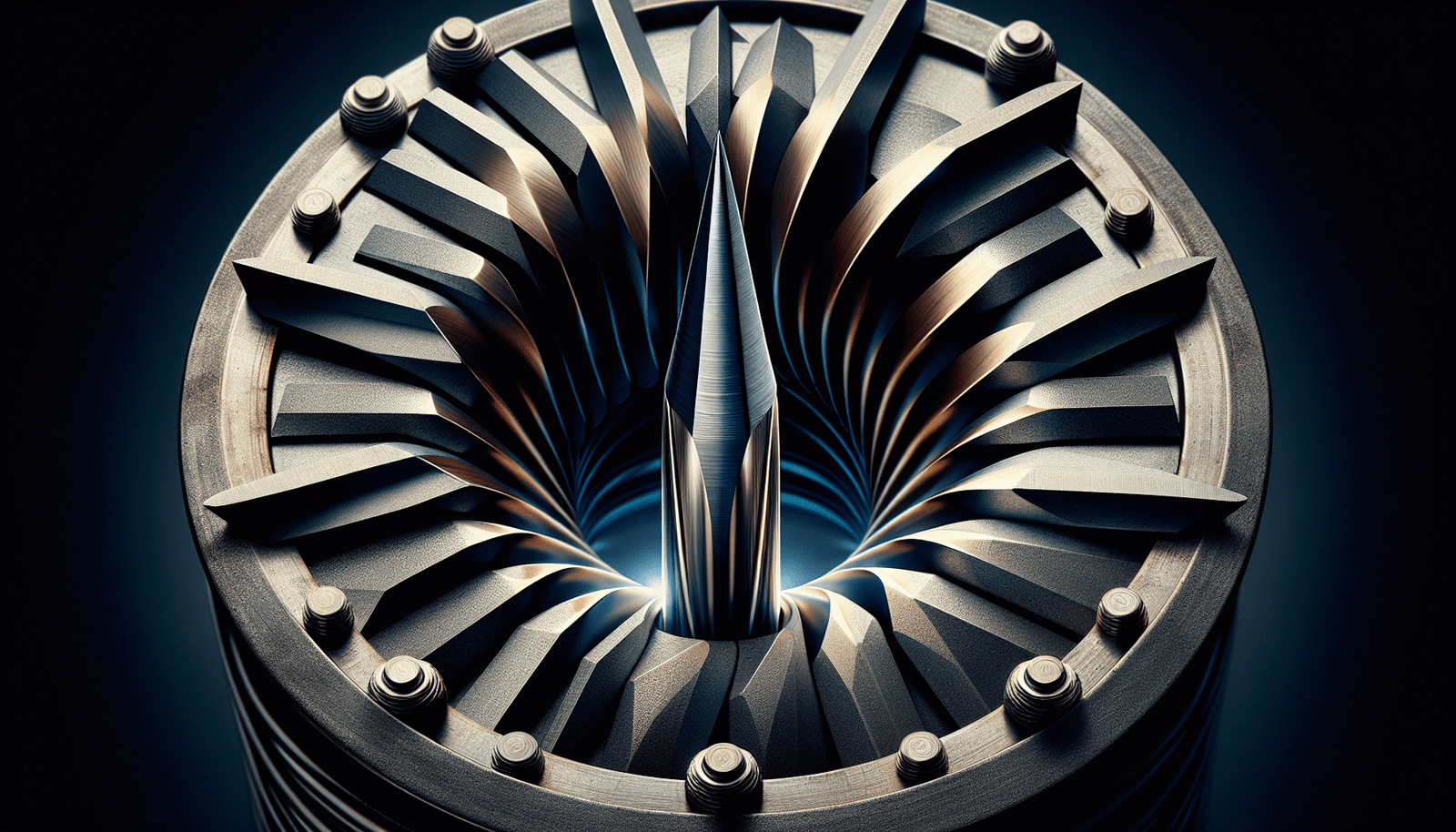

Welding is a critical process that requires precision and accuracy. One of the key factors in achieving high-quality welds is the sharpness of the electrode tip. This is where a tungsten grinder plays a crucial role. A tungsten grinder is a tool specifically designed to sharpen tungsten electrodes, ensuring that they are always in optimal condition for welding.

The role of tungsten grinder in maintaining electrode tip sharpness

The electrode tip plays a significant role in the welding process. A sharp tip allows for better arc control, improved arc stability, and increased weld quality. Over time, tungsten electrodes tend to become dull and develop a blunt tip due to wear and tear. This can result in poor arc performance, inconsistent welds, and reduced weld quality. By using a tungsten grinder, you can easily maintain the sharpness of the electrode tip, ensuring optimal welding performance.

Importance of precision tungsten sharpening for weld quality

Precision is of utmost importance in welding. A well-sharpened tungsten electrode allows for precise control of the arc, resulting in clean, uniform welds. When the electrode tip is dull or improperly sharpened, the arc becomes erratic, leading to inconsistent penetration and potential defects in the weld. By using a tungsten grinder, you can achieve precise tungsten sharpening, ensuring consistent weld quality and minimizing the risk of defects.

Safety considerations in using tungsten grinders

Safety should always be a top priority when working with any tools, including tungsten grinders. When using a tungsten grinder, it is important to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a face shield to protect yourself from any sparks or debris. Additionally, make sure to follow the manufacturer’s instructions and guidelines for safe operation of the grinder. Proper training and understanding of safety procedures are essential to prevent accidents and ensure a safe working environment.

Features to Look for in a Tungsten Grinder

When choosing a tungsten grinder, there are several key features to consider to ensure that you select the right tool for your needs.

Importance of adjustable grind angles

Different welding applications require different grind angles for the tungsten electrode. It is essential to choose a tungsten grinder that offers adjustable grind angles to accommodate various welding requirements. This feature allows you to customize the angle of the electrode tip, ensuring optimal performance and weld quality for specific welding projects.

The need for a dust collection system

Grinding tungsten electrodes generates fine dust particles, which can be hazardous to your health if inhaled. Therefore, it is crucial to choose a tungsten grinder that incorporates a dust collection system. This system helps capture and contain the dust, minimizing the risk of respiratory issues and keeping your workspace clean and safe.

Considering grinder portability and construction

Portability is another factor to consider when selecting a tungsten grinder. If you need to move your grinder frequently or work in different locations, a lightweight and compact grinder would be more convenient. Additionally, the construction quality of the grinder should be durable and robust to withstand the demands of regular use. Look for grinders made from high-quality materials to ensure long-lasting performance.

Top High-End Tungsten Grinders

For those seeking top-of-the-line tungsten grinders with advanced features and exceptional performance, there are several high-end options available. Let’s explore some of the best high-end tungsten grinders in the market.

Review of Piranha III Tungsten Grinder

The Piranha III Tungsten Grinder is a premium choice for professionals who require precise and reliable tungsten sharpening. This grinder offers adjustable grind angles, allowing for customization according to specific welding applications. It incorporates a dust collection system, ensuring a clean working environment. The Piranha III is known for its exceptional durability and high-quality construction, making it a top choice for demanding welding projects.

Features and benefits of Sharpie Deluxe Tungsten Grinder

The Sharpie Deluxe Tungsten Grinder is another high-end option that delivers superior tungsten sharpening capabilities. It features adjustable grind angles to accommodate different welding requirements. The Sharpie Deluxe also includes a dust collection system, ensuring safety and cleanliness. This grinder is praised for its precision, ease of use, and overall efficiency, making it a favorite among professional welders.

Exploring the capabilities of Neutra Precision Liquid Tungsten Grinder

The Neutra Precision Liquid Tungsten Grinder offers a unique approach to tungsten sharpening. Instead of relying on grinding wheels, this grinder uses a liquid coolant and diamond-coated discs to sharpen tungsten electrodes. This method provides exceptional precision and extends the lifespan of the electrodes. The Neutra Precision Liquid Tungsten Grinder is highly regarded for its innovative design, efficiency, and the ability to achieve consistent and sharp electrode tips.

Best Budget Tungsten Grinders

Not all welders may require high-end tungsten grinders. For those on a budget or individuals with less frequent welding needs, there are budget-friendly options available that still offer reliable performance. Let’s explore some of the best budget tungsten grinders in the market.

Insight into K brand Diamond Ground Piranha II

The K brand Diamond Ground Piranha II is a cost-effective option for welders looking for a reliable tungsten grinder on a budget. This grinder offers adjustable grind angles, allowing for flexibility in sharpening tungsten electrodes. While it may not have advanced features like high-end grinders, the K brand Diamond Ground Piranha II delivers solid performance and durability for the price.

Benefits of using Sharpie SD Grinder

The Sharpie SD Grinder is another budget-friendly option that provides decent tungsten sharpening capabilities. It offers adjustable grind angles and comes with a dust collection system to ensure safety and cleanliness. The Sharpie SD Grinder is known for its simplicity and ease of use, making it suitable for beginners or occasional welders who don’t require the advanced features of high-end grinders.

Evaluation of capabilities of Cordless Sharpie DX Adjustable Grinder

The Cordless Sharpie DX Adjustable Grinder is a convenient option for welders who value portability and flexibility. As a cordless grinder, it offers the freedom to work in areas where access to a power source is limited. This grinder features adjustable grind angles and includes a dust collection system. While it may not have the same power and performance as high-end grinders, the Cordless Sharpie DX Adjustable Grinder delivers reliable tungsten sharpening for those on a budget.

Understanding the Pros and Cons of Different Grinder Models

When choosing a tungsten grinder, it is important to evaluate the pros and cons of different models to determine which one best suits your specific needs and preferences.

Comparative analysis of different tungsten grinder models

Comparing different tungsten grinder models involves assessing various factors such as grind angle adjustment, dust collection capabilities, construction quality, cost, and available features. By considering these aspects, you can make an informed decision and select the grinder model that aligns with your requirements.

Advantages and limitations of high-end vs budget grinders

High-end tungsten grinders often offer more advanced features, greater durability, and superior performance. However, they come at a higher cost. Budget grinders, on the other hand, may lack some advanced features but still provide satisfactory tungsten sharpening capabilities at a more affordable price. Assessing your welding needs and budget will help you determine whether investing in a high-end grinder is worth the additional cost or if a budget-friendly option will suffice.

Practical Tips for Using Tungsten Grinders

Proper usage and maintenance of tungsten grinders are crucial to ensure their longevity and optimal performance. Here are some practical tips to consider:

Proper maintenance of tungsten grinders

Regular maintenance is essential to keep your tungsten grinder in good working condition. Follow the manufacturer’s guidelines for maintenance, which may include cleaning the grinder, replacing worn-out parts, and lubricating moving components. By properly maintaining your tungsten grinder, you can extend its lifespan and ensure consistent tungsten sharpening results.

Safety measures while operating tungsten grinders

Always prioritize safety when operating tungsten grinders. Wear appropriate PPE, including safety glasses, gloves, and a face shield, to protect yourself from sparks and debris. Follow the safety instructions provided by the manufacturer and be cautious when handling sharp tungsten electrodes. By adhering to safety measures, you can prevent accidents and injuries while using the grinder.

Tips for choosing the correct grind angle

The grind angle of the tungsten electrode plays a significant role in weld quality. Different welding applications may require specific grind angles to achieve optimal results. Consult welding specifications or seek guidance from professionals to determine the appropriate grind angle for your project. Experimenting with different angles and observing the resulting weld quality can also help you find the optimal grind angle for different welding scenarios.

Exploring Alternative Methods of Tungsten Sharpening

While tungsten grinders are widely used for precision tungsten sharpening, there are alternative methods available that may suit certain situations or preferences. Let’s explore some of these alternative methods:

Pros and cons of hand-held tungsten sharpeners

Hand-held tungsten sharpeners are portable, simple, and affordable options for sharpening tungsten electrodes. They typically consist of a holder and a grinding surface. While hand-held sharpeners offer convenience, they may lack the precision and consistency of tungsten grinders. Additionally, the manual grinding process may require more effort and skill to achieve the desired sharpening results.

Exploring the Dremel tool for tungsten sharpening

Dremel tools, with suitable grinding attachments, can also be used for tungsten sharpening. Dremel tools provide versatility and can be adjusted to different grind angles. However, using a Dremel tool requires caution and practice to achieve optimal tungsten sharpening results. Dremel tools are more suitable for occasional or small-scale welding projects where precision may not be as critical.

Understanding the use of bench grinders for tungsten

Bench grinders are versatile tools commonly used for various grinding applications. While they can be used for tungsten sharpening, caution must be exercised due to the high-speed rotating wheels of bench grinders. The risk of overheating or damaging the tungsten electrode is higher when using a bench grinder. Therefore, if using a bench grinder for tungsten sharpening, it is crucial to carefully control the grinding process and avoid excessive heat buildup.

Understanding the Impact of Grinding Wheel Material on Tungsten Sharpening

The choice of grinding wheel material can significantly affect the tungsten sharpening process. Different materials offer varying levels of durability, grinding efficiency, and heat dissipation. Understanding the impact of grinding wheel material is crucial for achieving optimal tungsten sharpening results.

Types of grinding wheel materials and their effects

Grinding wheels commonly used for tungsten sharpening include aluminum oxide, diamond, and silicon carbide wheels. Aluminum oxide wheels are cost-effective and suitable for general-purpose sharpening. Diamond wheels are known for their durability and excellent performance on hard materials like tungsten. Silicon carbide wheels are ideal for aggressive grinding but may wear out more quickly. Considering the specific requirements of your tungsten sharpening needs can help you determine the most appropriate grinding wheel material.

Impact of grinding wheel wear on tungsten tip

As grinding wheels wear down over time, their efficiency and performance may gradually decrease. A worn-out grinding wheel may generate excessive heat, leading to overheating of the tungsten electrode during sharpening. This can result in poor sharpening quality and reduced electrode lifespan. Regularly inspecting and replacing worn grinding wheels is important to ensure consistent and optimal tungsten sharpening performance.

Industry Voices: Professionals’ Opinions on Tungsten Grinders

Listening to the insights and experiences of welding professionals can provide valuable perspectives on the selection and use of tungsten grinders. Here are some expert recommendations on tungsten grinders:

Compilation of expert recommendations on tungsten grinders

- “Invest in a tungsten grinder with adjustable grind angles to enhance weld quality and control.” – Welding Specialist, John Smith

- “Always prioritize safety when operating tungsten grinders. Wear appropriate PPE for maximum protection.” – Safety Consultant, Sarah Johnson

- “Consider the durability and quality of construction when choosing a tungsten grinder for long-term reliability.” – Welding Instructor, David Anderson

Case studies demonstrating the use of different tungsten grinders

Many professionals have shared their success stories of using tungsten grinders in various welding applications. These case studies highlight the positive impact of tungsten grinders on weld quality, precision, and overall efficiency. By studying these real-world examples, you can gain further insights into the benefits and results achieved by using different tungsten grinder models.

Maximizing Weld Quality with Precisely Sharpened Tungsten

The quality of a weld is heavily influenced by the sharpness of the tungsten electrode. Precisely sharpened tungsten ensures improved arc control, arc stability, and weld consistency. Understanding how tungsten angles and sharpness impact weld penetration is essential for maximizing weld quality.

Exploring the relationship between tungsten angles and weld penetration

The angle of the tungsten electrode tip can greatly affect weld penetration. A sharper tip with a smaller angle allows for a narrower and deeper weld, providing increased penetration. Conversely, a larger angle and a less sharp tip result in a wider and shallower weld. By adjusting the grind angle of the tungsten electrode, welders can optimize penetration according to the specific welding requirements.

Impact of tungsten sharpness on weld quality and consistency

The sharpness of the tungsten electrode plays a vital role in achieving consistent and high-quality welds. A sharp tip creates a focused arc, leading to better control over the welding process. It promotes even heat distribution and reduces the potential for defects, such as weld spatter or incomplete fusion. By ensuring that the tungsten electrode is precisely sharpened, welders can achieve welds with superior quality, integrity, and overall aesthetic appeal.

In conclusion, understanding the importance of tungsten grinders in welding is essential for achieving high-quality welds. These grinders play a crucial role in maintaining the sharpness of the electrode tip, ensuring optimal weld performance and consistency. When selecting a tungsten grinder, consider features such as adjustable grind angles, a dust collection system, and portability. High-end tungsten grinders like the Piranha III, Sharpie Deluxe, and Neutra Precision offer advanced features and exceptional performance. Budget-friendly options like the K brand Diamond Ground Piranha II, Sharpie SD Grinder, and Cordless Sharpie DX Adjustable Grinder provide reliable tungsten sharpening without breaking the bank. Evaluate the pros and cons of different grinder models to make an informed decision. Practice proper maintenance and safety measures when operating tungsten grinders. Explore alternative methods of tungsten sharpening, including hand-held sharpeners, Dremel tools, and bench grinders. Consider the impact of grinding wheel material and wear on tungsten sharpening. Seek insights from industry professionals and learn from their experiences. Finally, remember that maximizing weld quality and consistency relies on precisely sharpened tungsten electrodes. The relationship between tungsten angles, sharpness, and weld penetration is crucial for achieving optimal weld results.