In this friendly and informative article, we will take you through the essential safety equipment that every beginner welder should know about. Welding can be an exciting and fulfilling skill to learn, but it’s crucial to prioritize safety at all times. We’ll discuss the importance of protective gear such as helmets, gloves, and goggles, as well as the significance of proper ventilation and fire safety measures. Whether you’re just starting your journey as a welder or simply curious about the subject, this beginner’s guide to welding safety equipment will provide you with the knowledge and confidence to tackle your projects with peace of mind.

Understanding the Importance of Welding Safety Equipment

Importance of welding safety

When it comes to welding, safety should always be a top priority. Welding involves working with high temperatures, sparks, and potentially hazardous fumes. Without the proper safety equipment, you put yourself at risk of injury or even long-term health issues. Welding safety equipment is designed to protect you from potential dangers and create a safe working environment.

Potential risks involved in welding

Welding poses several risks that can be harmful if not properly addressed. The intense heat generated during the welding process can cause burns to your skin if you are not wearing the appropriate protective clothing. In addition, the sparks and flying debris can potentially damage your eyes if you do not use safety glasses or goggles. Another significant risk is the inhalation of fumes and gases produced during welding, which can lead to respiratory issues if you do not use adequate respiratory protection. Additionally, loud noises generated during welding can damage your hearing if you do not use proper hearing protection.

Safety Clothing for Welding

Overview of safety clothing

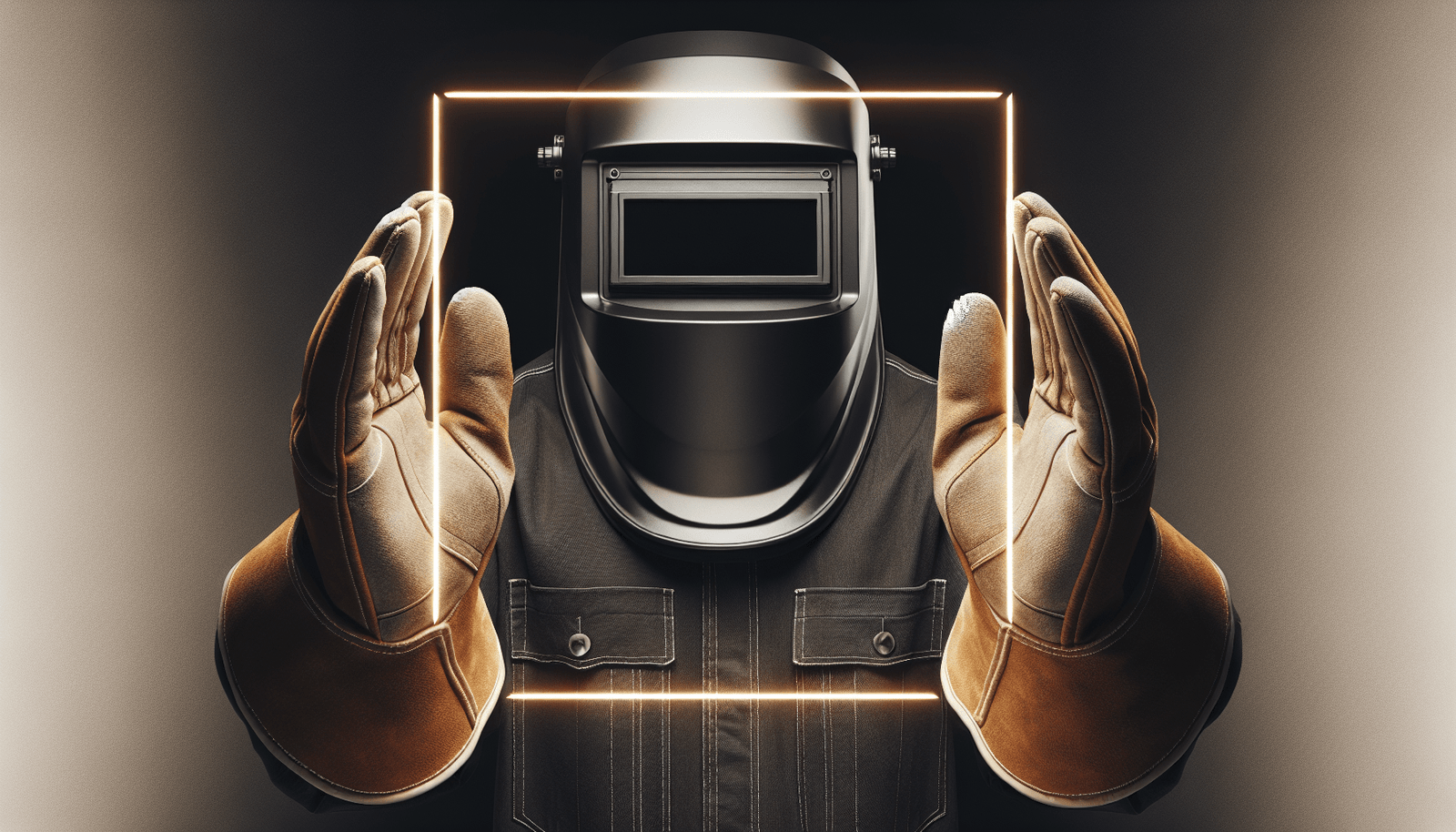

Safety clothing plays a crucial role in protecting the welder from burns, sparks, and flying debris. It is an essential part of welding safety equipment. Safety clothing typically includes welding jackets, welding aprons, welding gloves, welding sleeves, and bibs. These garments are specifically designed to withstand high temperatures and provide a barrier between the welder and potential hazards.

Welding jackets and their importance

Welding jackets are specifically designed to protect the welder’s upper body, including the torso and arms. They are typically made from flame-resistant materials that can withstand high levels of heat. A good quality welding jacket provides excellent insulation against the heat and prevents sparks from reaching the skin, reducing the risk of burns.

The use of welding aprons

Welding aprons are another essential piece of safety clothing for welders. They provide protection to the lower body, particularly the legs and groin area. Welding aprons are also made from flame-resistant materials and are designed to shield the welder from sparks, hot metal, and radiation. By wearing a welding apron, you can prevent burns and other injuries to your lower body.

Importance of welding gloves

Welding gloves are crucial for hand protection while welding. They are made from durable materials that can withstand high temperatures and protect against burns and cuts from sharp objects. The right welding gloves should be sturdy enough to provide adequate dexterity for welding tasks while still offering sufficient protection.

About welding sleeves and bibs

Welding sleeves and bibs are additional safety clothing options that can provide extra protection where needed. Welding sleeves cover the arms and provide an added layer of defense against sparks and heat. Welding bibs, on the other hand, protect the chest and neck area. These accessories can be used in combination with welding jackets and aprons to enhance overall safety.

Welding Helmets

Overview of welding helmets

A welding helmet is one of the most critical pieces of safety equipment for welders. It provides protection for the face, eyes, and neck from sparks, intense light, and harmful radiation. Welding helmets are designed to automatically darken when the welding arc is struck, shielding the welder’s eyes from harmful UV and infrared rays.

Understanding different types of welding helmets

There are several types of welding helmets available to meet different needs. Passive welding helmets have a fixed shade that does not automatically adjust. They require the welder to manually lift the helmet to see the workpiece, which can be inconvenient. On the other hand, auto-darkening welding helmets have technology that automatically adjusts the shade level depending on the brightness of the welding arc. This feature allows for greater convenience and increased productivity.

Features to look for in a welding helmet

When choosing a welding helmet, it is essential to consider certain features. Look for a helmet with a wide viewing area to provide a clear vision of the workpiece. Adjustable sensitivity and delay settings are also helpful, as they allow you to customize the helmet’s response to different welding conditions. Additionally, ensure that the helmet is comfortable and lightweight, as this will contribute to a more enjoyable and safer welding experience.

Safety Glasses and Goggles

Need for safety glasses and goggles in welding

In addition to a welding helmet, safety glasses or goggles are essential for eye protection during welding. The intense brightness and sparks generated during welding can cause severe damage to the eyes if left unprotected. Safety glasses and goggles provide an additional layer of defense against potential hazards that may bypass the helmet’s protection or for tasks that do not require a full welding helmet.

Choosing the right safety glasses and goggles

When selecting safety glasses or goggles for welding, ensure they meet the appropriate safety standards. Look for glasses or goggles with lenses that are impact-resistant and provide adequate coverage to protect the entire eye area. Additionally, choose lenses with suitable shading to provide the necessary protection against ultraviolet and infrared radiation.

Proper use and maintenance of welding safety glasses and goggles

To ensure the continued effectiveness of your safety glasses or goggles, it is important to use and maintain them properly. Always wear them during welding tasks, even when wearing a welding helmet. Clean them regularly using suitable cleaning solutions and a soft cloth to remove any dirt or debris. Inspect them for any signs of damage, such as scratches or cracks, and replace them if necessary.

Respiratory Protection in Welding

Importance of respiratory protection

Respiratory protection is crucial in welding due to the fumes and gases produced during the process. Inhaling these hazardous substances can lead to respiratory issues and long-term health problems. Using respiratory protection equipment can reduce the risk of exposure and ensure that you breathe in clean air while welding.

Understanding different types of respiratory equipment

There are different types of respiratory protection equipment available for welders. Disposable respirators, also known as dust masks, are a cost-effective option for tasks with low fume exposure. Half-mask and full-face respirators provide a higher level of protection and often require the use of replaceable cartridges or filters. Powered air-purifying respirators (PAPRs) offer even greater protection by delivering filtered air to the welder.

Proper use and maintenance of respiratory protection gear

To benefit from respiratory protection gear, it is important to use it correctly. Follow all manufacturer instructions for fitting and wearing the equipment. Ensure that the mask or respirator forms a proper seal on your face to prevent any contaminants from entering. Regularly inspect the equipment for any signs of damage or wear and replace filters or cartridges as recommended by the manufacturer.

Hearing Protection Equipment

Understanding the importance of hearing protection

Welding often involves loud noises, which can damage your hearing if not properly protected. Prolonged exposure to high noise levels can lead to hearing loss, making hearing protection equipment essential for welders. By using the appropriate hearing protection, you can prevent long-term damage to your ears and maintain good hearing health.

Different types of hearing protection equipment

There are various types of hearing protection equipment available to suit different needs and preferences. Earplugs are a common choice and come in disposable or reusable options. Earmuffs, on the other hand, cover the entire ear and provide a higher level of noise reduction. Some earmuffs even come equipped with built-in communication systems for added convenience.

Choosing the right hearing protection

When selecting hearing protection equipment, consider the noise level in your work environment and the duration of exposure. Look for products with a Noise Reduction Rating (NRR) that matches your needs. Ensure that the hearing protection is comfortable to wear for extended periods and does not interfere with other safety equipment, such as welding helmets.

Footwear for Welding Safety

Importance of appropriate footwear

Having the right footwear is crucial for welding safety. Your feet are at risk of injury from falling objects, sparks, and hot metal during the welding process. Proper footwear provides protection against these hazards and helps prevent accidents and injuries in the workplace.

Types of safety shoes or boots suitable for welding

Safety shoes or boots for welding should meet specific criteria to ensure adequate protection. Look for footwear with steel toes to protect against falling objects and compression. The soles of the shoes should be heat-resistant and provide good traction to prevent slips and falls. Additionally, the boots should cover the ankle for added stability and protection.

Considerations when choosing welding footwear

When choosing welding footwear, ensure that the shoes or boots fit well and are comfortable to wear for long periods. Opt for footwear that is made from durable and high-quality materials to withstand the harsh conditions of welding. It is also important to regularly inspect your welding footwear for any signs of wear or damage and replace them as necessary to maintain optimal safety.

Welding Safety: Understanding Fire Hazards

Identifying potential fire hazards

Fire hazards are a significant concern in welding, as the process involves open flames, sparks, and high temperatures. It is crucial to identify and address potential fire hazards to ensure a safe working environment. Common fire hazards in welding include combustible materials, flammable gases, electrical equipment, and improper storage of flammable substances.

Fire extinguishing equipment suitable for welding environments

Having the appropriate fire extinguishing equipment is essential to quickly and effectively respond to fires in welding environments. Fire extinguishers should be readily accessible and specifically designed for use with flammable metals, such as Class D fire extinguishers. Additionally, fire blankets can be used to smother small fires or wrap around objects to prevent them from catching fire.

Importance of fire-resistant materials in welding

Using fire-resistant materials is crucial to prevent the spread of fire and protect the surrounding areas. Fire-resistant welding blankets or curtains can be used to create a barrier between the welding operation and combustible materials. These materials are designed to withstand high temperatures, sparks, and flying debris, helping to minimize the risk of fire and injury.

General Safety Practices in Welding

Maintaining a clean work environment

Maintaining a clean and organized work environment is essential for welding safety. Clearing away any debris, flammable materials, or clutter can reduce the risk of accidents or fires. Regularly clean your tools and equipment to ensure they are in good working condition and free from any potential hazards.

Proper equipment handling and storage

Proper handling and storage of welding equipment are important for both safety and equipment longevity. Always follow manufacturer instructions for handling and using the equipment. Ensure that welding machines and power cords are in good condition and free from damage. When not in use, store equipment in a clean and dry area, away from moisture or other potential hazards.

Avoiding risks and potential hazards

Welders should be trained to identify and avoid potential risks and hazards in their work environment. This includes being aware of the location of fire exits, emergency shutdown procedures, and any specific safety protocols. By being proactive and cautious, welders can prevent accidents and minimize the potential for injuries during welding operations.

Regular Maintenance and Checking of Welding Safety Equipment

Importance of regular safety equipment checks

Regular maintenance and checking of welding safety equipment are crucial for ensuring its effectiveness. Over time, safety equipment can wear out or become damaged, compromising its ability to protect the welder. Regular checks help identify any issues early on and allow for prompt repairs or replacements, minimizing the risk of accidents and injuries.

Steps for maintaining welding safety equipment

Maintaining welding safety equipment involves several steps. Start by inspecting each piece of equipment for any signs of wear and tear. Check the condition of safety clothing, helmets, glasses, goggles, and respiratory equipment. Replace any damaged or worn-out parts or equipment as needed. Clean and store the equipment properly to extend its lifespan and maintain its functionality.

Signs of wear and tear to look for

When checking welding safety equipment, keep an eye out for signs of wear and tear. Look for frayed seams or holes in safety clothing, as these can compromise its ability to protect against sparks and heat. Inspect welding helmets for cracks or damaged lens filters. Check the straps and seals of safety glasses and goggles for any signs of deterioration. Replace any equipment that shows significant wear or damage.

Replacing and updating safety equipment

Regularly assess your welding safety equipment to determine if any upgrades or replacements are necessary. As technology advances, new safety features may become available that can enhance protection and comfort. Stay up to date with industry standards and regulations to ensure that your safety equipment meets the necessary requirements. Investing in high-quality, reliable safety equipment is essential for maintaining a safe and secure welding environment.

In conclusion, understanding the importance of welding safety equipment is crucial for every welder. By recognizing the potential risks involved and adopting the correct safety practices and equipment, you can ensure a safer and healthier welding experience. Remember to always wear the appropriate safety clothing, helmets, goggles, and respiratory protection. Regularly maintain and check your safety equipment, and promptly replace any damaged or worn-out parts. By prioritizing safety in welding, you can minimize the risk of accidents and create a secure work environment.