In the world of welding, having the right tools is essential for success. Whether you’re a seasoned professional or just getting started, having the proper equipment can make all the difference in the quality of your work. From welding helmets to gloves, there are a variety of tools and consumables that every welder should have in their arsenal. In this article, we will explore some of these essential tools and discuss their importance in ensuring a safe and efficient welding process. So, grab your welding mask and let’s dive into the world of welding consumables!

Safety Gear for Welding

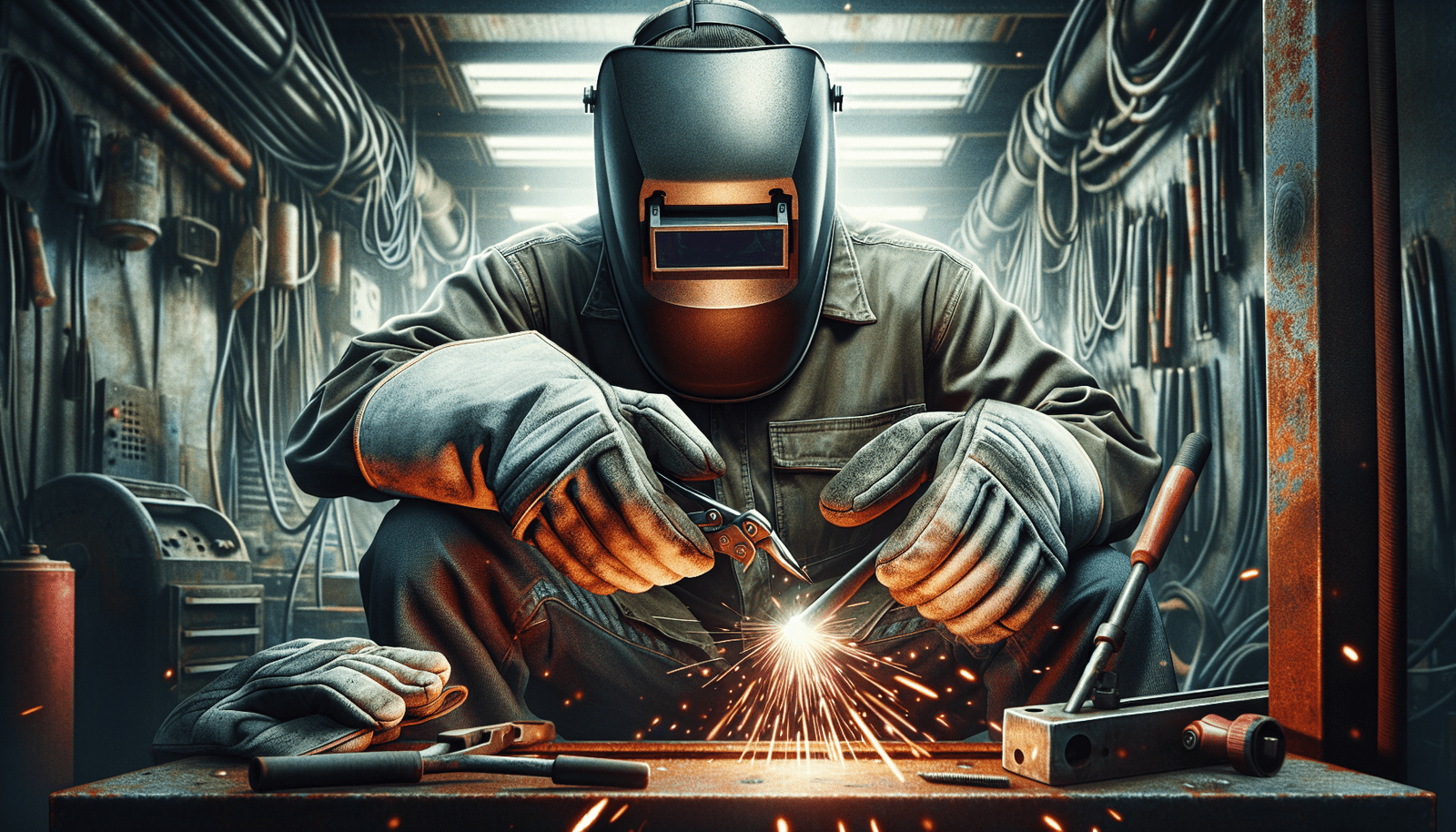

When it comes to welding, safety should always be a top priority. Working with intense heat, sparks, and potential hazards requires proper protective gear. Here are some essential safety gear items that you should have in your welding arsenal.

Safety Glasses and Helmets

Protecting your eyes and face is crucial while welding. Safety glasses shield your eyes from harmful UV rays, flying debris, and sparks. They should have side shields for maximum protection. On the other hand, welding helmets offer full face and head coverage, and they are specifically designed to protect your eyes from the intense light emitted during welding. Look for helmets with auto-darkening lenses, as they provide better visibility and allow you to keep the helmet on while setting up your weld.

Welding Gloves and Jackets

Welding gloves are an absolute must when working with hot materials and sparks. They should be made of flame-resistant material such as leather to protect your hands from burns. Additionally, welders should wear flame-resistant jackets or aprons to safeguard their upper body and arms from heat and spatter. Choose jackets that are comfortable, durable, and provide ample coverage to ensure maximum protection.

Respirators for Welding

Welding fumes can be hazardous to your health, as they contain harmful particles and gases. To protect yourself from these airborne contaminants, it is essential to wear a respirator. Respirators specifically designed for welding have filters that remove the dangerous fumes, allowing you to breathe clean air while working. Look for respirators that fit securely and comfortably, and ensure they comply with the appropriate safety standards.

Welding Aprons

Welding aprons are an additional layer of protection to shield your clothes and body from sparks, molten metal, and other welding hazards. They are typically made of flame-resistant material and offer coverage for your torso and legs. Welding aprons come in various styles, including leather or fire-resistant cotton, so choose one that suits your needs and provides the level of protection required for your welding projects.

Welding Machines and Equipment

Having the right welding machines and equipment is essential to achieve high-quality welds efficiently and safely. Here are some common types of welding machines that you should consider for your welding projects.

MIG Welders

MIG (Metal Inert Gas) welders are one of the most popular welding machines due to their versatility and ease of use. They use a consumable wire electrode and a shielding gas to create strong and clean welds. MIG welders are suitable for a wide range of materials and can be used for both indoor and outdoor projects. Make sure to select a MIG welder that matches the thickness of the materials you will be working with.

TIG Welders

TIG (Tungsten Inert Gas) welders are known for their precision and ability to weld various metals. They use a non-consumable tungsten electrode and a separate filler material to create precise and high-quality welds. TIG welding is commonly used for stainless steel, aluminum, and other non-ferrous metals. TIG welders require more skill and practice compared to other welding processes, but they offer excellent control and produce clean welds.

Stick Welders

Stick welders, also known as Arc welders, are the most basic and affordable type of welding machine. They use a consumable electrode covered in flux to create an electric arc between the electrode and the workpiece, which generates heat and forms the weld. Stick welding is suitable for heavy-duty applications and rough surfaces. These welders are often used in construction, pipelines, and maintenance and repair projects.

Multi-process Welders

For maximum versatility, multi-process welders are an excellent option. These machines allow you to switch between different welding processes, such as MIG, TIG, and Stick welding, with ease. Multi-process welders are ideal for welders who work with a variety of materials and need the flexibility to adapt to different projects. While they may be pricier than single-process welders, they offer convenience and efficiency for professional welders.

Power and Hand Tools

In addition to welding machines, various power and hand tools are essential for a successful welding operation. These tools help prepare the workpieces, clean welds, and perform other necessary tasks. Here are some power and hand tools every welder should have in their toolkit.

Angle Grinders

Angle grinders are versatile tools that can be used for cutting, grinding, and polishing metal. They can be equipped with different types of grinding discs, abrasive wheels, and wire brushes to suit various welding-related tasks. Angle grinders are particularly useful for removing weld splatter, cleaning up weld joints, and shaping metal.

Wire Brushes

Wire brushes are essential for removing rust, paint, and other contaminants from the metal surfaces before welding. They are available in different sizes and bristle types, such as stainless steel or brass. Wire brushes are used to clean the workpiece, ensuring a clean and properly bonded weld. Regularly cleaning and maintaining your wire brushes will ensure their effectiveness and prolong their lifespan.

Hand Files

Hand files come in various shapes and sizes and are used to smooth and shape metal surfaces. They are particularly useful for accessing tight spaces and removing sharp edges from welds. Hand files are available in different grits, allowing you to achieve the desired level of smoothness and precision.

Drill

A drill is a versatile tool that can be used for drilling holes, making pilot holes, and even tapping threads for bolts. Having a reliable drill and a set of drill bits in your welding toolkit will come in handy for various tasks, such as creating holes for plug welds or drilling into metal supports for welding fixtures. Choose a drill that is powerful enough to handle the materials you will be working with.

Welding Clamp and Holders

Welding clamps and holders are crucial for securing workpieces in the desired position during the welding process. They help ensure stability and accuracy while creating strong and consistent welds. Here are some common types of clamps and holders you should consider for your welding projects.

C-clamps

C-clamps are versatile clamping tools that can be used to hold workpieces together or secure them to a work surface. They have a simple design, with a threaded screw that tightens the clamp to provide pressure. C-clamps come in various sizes, and their sturdy construction makes them suitable for heavy-duty applications.

Vise-Grip Locking Pliers

Vise-Grip locking pliers, also known as mole grips, are specially designed to hold materials securely in place. These pliers feature a quick-release mechanism that allows for easy adjustment and fastening. Vise-Grip locking pliers come in handy when you need to hold small parts or awkwardly shaped workpieces during welding.

Sheet Metal Clamps

Sheet metal clamps are specifically designed to secure thin metal sheets in place during welding. They have a low-profile design and provide even pressure distribution to prevent distortion or warping of the metal. Sheet metal clamps are ideal for welding body panels, automotive repairs, or any project that involves thin sheet metal.

Ground Clamps

Ground clamps are essential for creating a proper electrical connection between the workpiece and the welding machine’s ground cable. A secure and reliable ground connection is crucial for obtaining consistent welds and preventing electrical issues. Ground clamps are available in different sizes and designs, and they should be securely attached to the workpiece to ensure good electrical contact.

Welding Table and Positioners

Having the right welding table and positioners can greatly enhance your welding experience and productivity. These tools provide a stable and adjustable work surface, allowing you to position your workpiece at the desired angle for optimal weld quality. Here are some types of welding tables and positioners to consider.

Flat Welding Tables

Flat welding tables are versatile work surfaces that provide a stable platform for welding. They are typically made of heat-resistant materials and have a smooth surface that allows for easy maneuverability of the workpiece. Flat welding tables are available in various sizes and configurations, and some even feature built-in slots and clamp holes for securing the workpiece.

Angle Welding Tables

Angle welding tables, also known as welding jigs, are designed to hold workpieces at specific angles. These tables typically have adjustable angles ranging from 0 to 180 degrees, allowing for precise positioning of the workpiece. Angle welding tables are commonly used for welding frames, brackets, and other projects that require angled joints.

Rotary Welding Positioners

Rotary welding positioners are motorized devices that allow for the rotation of the workpiece during welding. They can be manually or automatically controlled, and they offer continuous rotation or preset angles for precise positioning. Rotary positioners are particularly useful when welding cylindrical objects or for projects that require all-around access to the workpiece.

Manual Welding Positioners

Manual welding positioners, also known as welding turntables, are manually operated devices that rotate the workpiece. They are less complex and more affordable than rotary positioners, making them suitable for smaller welding projects. Manual positioners come in various sizes and weight capacities, so choose one that can accommodate your workpiece dimensions and weight.

Markers and Measures for Welding

Accurate measurements and markings are crucial for precise and consistent welding. Having the right markers and measures on hand will help you achieve accurate weld joint preparation and alignment. Here are some commonly used markers and measures in welding.

Chalk Markers

Chalk markers are temporary markers that are commonly used in welding for marking measurements or guidelines on metal surfaces. The marks made by chalk markers can be easily wiped off or removed with a wire brush, making them ideal for temporary markings that need to be erased.

Welding Gauges

Welding gauges are specialized tools used to measure the dimensions and alignment of welds. They come in various shapes and sizes and are designed for different types of measurements, such as fillet weld size, groove angle, or undercut depth. Welding gauges help ensure that the weld meets the required specifications and standards.

Rulers and Tape Measures

Rulers and tape measures are essential tools for measuring various dimensions during welding. They are used to determine the length, width, and height of workpieces, as well as the distances between weld joints. Having a reliable ruler or tape measure with clear markings and accurate measurements is crucial for achieving precise weld dimensions.

Angle Finder

An angle finder, also known as a protractor, is a handy tool for measuring angles accurately. It helps determine the angle between two surfaces or the angle of a bend or joint. Angle finders come in different designs, such as digital or magnetic, and they provide precise angle measurements for accurate weld preparation and alignment.

Cleaning and Finishing Tools

After completing a weld, it is essential to clean and finish the weld to ensure its durability and appearance. Cleaning and finishing tools help remove slag, splatter, and other residue from the weld, resulting in a clean and smooth finish. Here are some commonly used cleaning and finishing tools.

Welding Hammers

Welding hammers, also known as chipping hammers or slag hammers, are essential for removing slag and spatter from the welded joints. They have a chisel-like end for chipping away the excess material and a pointed end for precise cleaning. Welding hammers are typically made of heat-resistant materials and are designed to withstand heavy use.

Chipping Hammers

Similar to welding hammers, chipping hammers are used to remove slag, spatter, and other unwanted debris from the welded surfaces. They have a sharp chisel-like end for chipping and a flat end for striking or cleaning. Chipping hammers come in various styles and sizes, and some even feature a wire brush integrated into the handle for additional cleaning convenience.

Grinders

Grinders, equipped with grinding discs or abrasive wheels, are versatile tools used for various cleaning and finishing tasks in welding. They are commonly used to remove rough weld beads, smooth out rough surfaces, or reshape metals. Grinders should be used with caution and proper safety precautions, as they generate sparks and can be aggressive on the metal surface.

Wire Brushes

Wire brushes, mentioned earlier for surface preparation, are also useful for cleaning and finishing welds. They are particularly effective in removing light rust, scale, or discoloration from the weld, resulting in a clean and polished appearance. Wire brushes can be attached to drills or used by hand for small and intricate areas that require cleaning.

Filler Metals and Consumables

Filler metals and consumables are indispensable components in welding that help create strong and durable welds. Here are some commonly used filler metals and consumables.

Electrodes

Electrodes are consumable wires or rods used in various welding processes, such as Stick, TIG, and MIG welding. They provide a conductive path for the electric arc and introduce a filler material into the weld joint. Electrodes come in different types, sizes, and materials, so it’s important to choose the right electrode for the specific welding process and the type of metal being welded.

Fluxes

Fluxes are used in certain welding processes, notably Stick and Flux-Cored Arc Welding (FCAW), to protect the weld pool from atmospheric contamination. The flux coating on the electrode releases gases to shield the weld from oxygen and impurities, ensuring a clean and strong bond. Fluxes are available in different formulations, so select the appropriate flux for your welding process and the type of material being welded.

Gas

Shielding gases, such as argon, carbon dioxide, or a mixture of gases, are commonly used in welding processes like TIG and MIG welding. The shielding gas creates a protective atmosphere around the weld, preventing atmospheric contaminants from reacting with the weld pool. The choice of shielding gas depends on the specific welding process, the type of metal, and the desired weld characteristics.

Wire

Welding wire is used in MIG welding, where a continuous wire electrode is fed through the welding gun and forms the weld pool. The wire provides the filler material for the weld joint and is available in different diameters and materials to suit various welding applications. Choosing the right wire diameter and material is essential for achieving strong and clean welds.

Welding Accessories

In addition to the essential tools and equipment, there are various accessories that can enhance your welding experience and efficiency. Here are some welding accessories to consider.

Hose Reels

Hose reels help keep your welding hoses, cables, and wires organized and protected. They prevent tangling and ensure easy access to the required length of hose or cable. Hose reels are available in different sizes and mounting options, allowing you to customize your workspace and reduce clutter.

Welding Curtains

Welding curtains offer protection from sparks, UV radiation, and welding fumes. They act as a barrier, preventing dangerous materials from reaching nearby workers or sensitive equipment. Welding curtains are typically made of flame-resistant materials and can be easily hung or mounted to create a safe welding enclosure.

Cable Covers

Cable covers are protective sleeves that cover welding cables, hoses, and wires to prevent damage from abrasion, wear, or exposure to chemicals or rough surfaces. They provide an additional layer of safety and ensure the longevity of your welding cables. Cable covers come in various sizes and materials, so choose the appropriate cover for your specific welding setup.

Welding Carts

Welding carts are rolling platforms designed to transport welding machines, gas cylinders, and other welding accessories. They provide convenient mobility and storage for your welding equipment, allowing you to easily move from one location to another. Welding carts often feature shelves or compartments for organized storage of consumables and tools.

Maintenance and Repair Tools for Welding Machine

To keep your welding machine in optimal condition, regular maintenance and repairs are necessary. Having the right tools on hand will ensure that you can address any issues that may arise. Here are some common maintenance and repair tools for welding machines.

Replacement Tips

When it comes to MIG or TIG welding, the tips of the welding torch are prone to wear and need to be replaced regularly. Replacement tips ensure a consistent and precise arc, reducing issues such as spatter or poor weld quality. Be sure to have a selection of replacement tips that fit your specific welding torch.

Gas Diffusers

Gas diffusers are responsible for evenly distributing the shielding gas around the weld pool, ensuring proper gas coverage and protection. Over time, gas diffusers can become clogged or damaged, affecting the weld quality. Having spare gas diffusers on hand allows you to quickly replace them and maintain the integrity of your shielding gas supply.

Nozzles

Nozzles, also known as contact tips or gas cups, are an important component in MIG and TIG welding torches. They help control the flow of shielding gas and guide the electrode wire for precise and efficient welds. Nozzles can become worn, damaged, or clogged, affecting the welding performance. It’s important to have spare nozzles in different sizes to ensure uninterrupted welding operations.

Drive Rolls

Drive rolls, also called feed rolls, are responsible for feeding the electrode wire through the welding torch. They grip and push the wire, ensuring a steady and consistent wire feed. Over time, drive rolls can wear out, causing wire feeding issues and affecting the weld quality. Replacing worn drive rolls is crucial to maintain the efficiency and reliability of your wire feeding system.

In conclusion, having the right tools and equipment is essential for safe and efficient welding. From safety gear to welding tables, power tools, clamps, and maintenance tools, each item plays a vital role in achieving high-quality welds. Remember to choose tools that are suitable for your specific welding projects and materials. With the right tools and a commitment to safety, you’ll be well-prepared to tackle any welding task that comes your way. Happy welding!