If you are a welding enthusiast or a professional welder, you know how essential it is to have properly sharpened tungsten electrodes for precise and efficient welding. But do you know how to maintain and use welding tungsten sharpeners correctly? In this article, you’ll learn everything you need to know about keeping your sharpeners in top-notch condition and utilizing them effectively. From simple maintenance tips to step-by-step instructions on sharpening tungsten electrodes, this guide will ensure that you have the knowledge and skills to achieve exceptional welding results. So, let’s dive in and discover the secrets of maintaining and using welding tungsten sharpeners like a pro!

Understanding the Importance of Welding Tungsten Sharpeners

When it comes to welding, the importance of having a sharp tungsten cannot be overstated. A sharp tungsten electrode is crucial for creating efficient and high-quality welds. It allows for better control of the welding arc, resulting in more precise and consistent welds. Not only does a sharp tungsten improve the overall weld quality, but it also increases the lifespan of the electrode, saving you time and money in the long run. In order to achieve these benefits, it is essential to have the right tools, such as welding tungsten sharpeners, in your arsenal.

Importance of Tungsten Sharpeners in the Welding Process

Welding tungsten sharpeners play a vital role in the welding process by ensuring that the tungsten electrode remains sharp and in optimal condition. Over time, tungsten electrodes can become dull and rounded, affecting the quality of the weld. By utilizing a tungsten sharpener, you can restore the sharpness of the electrode, resulting in improved weld performance. A sharp tungsten electrode allows for better arc ignition, better arc stability, and increased weld penetration. It also helps reduce tungsten contamination in the weld, ensuring a clean and precise result. By investing in a reliable tungsten sharpener, you are investing in the overall success of your welding projects.

The Role of a Sharp Tungsten in Creating Efficient Welds

A sharp tungsten electrode is essential for creating efficient welds. When the electrode is dull or improperly sharpened, it can lead to numerous issues, such as arc wandering, difficulty in initiating the arc, and inconsistent weld penetration. These problems can result in poor weld quality, wasted materials, and increased rework. On the other hand, a properly sharpened tungsten electrode provides a stable and focused welding arc, ensuring accurate and precise welds. The sharp point of the tungsten allows for better control and maneuverability, enabling welders to achieve the desired result with ease. By using a welding tungsten sharpener to maintain the sharpness of your electrodes, you can maximize your welding efficiency and produce high-quality welds consistently.

Types of Welding Tungsten Sharpeners

There are two main types of welding tungsten sharpeners available on the market: benchtop tungsten sharpeners and handheld tungsten sharpeners.

Benchtop Tungsten Sharpeners

Benchtop tungsten sharpeners are larger, stationary machines designed for heavy-duty use. They are equipped with a grinding wheel that rotates against the tungsten electrode, sharpening it to the desired point. Benchtop sharpeners often come with adjustable angle settings, allowing you to choose the desired angle for your specific welding application. They are perfect for professional welders or workshops that require frequent welding tungsten sharpening. With their robust construction and powerful grinding wheels, benchtop sharpeners can handle a large volume of tungsten electrodes and provide consistent and precise sharpening results.

Handheld Tungsten Sharpeners

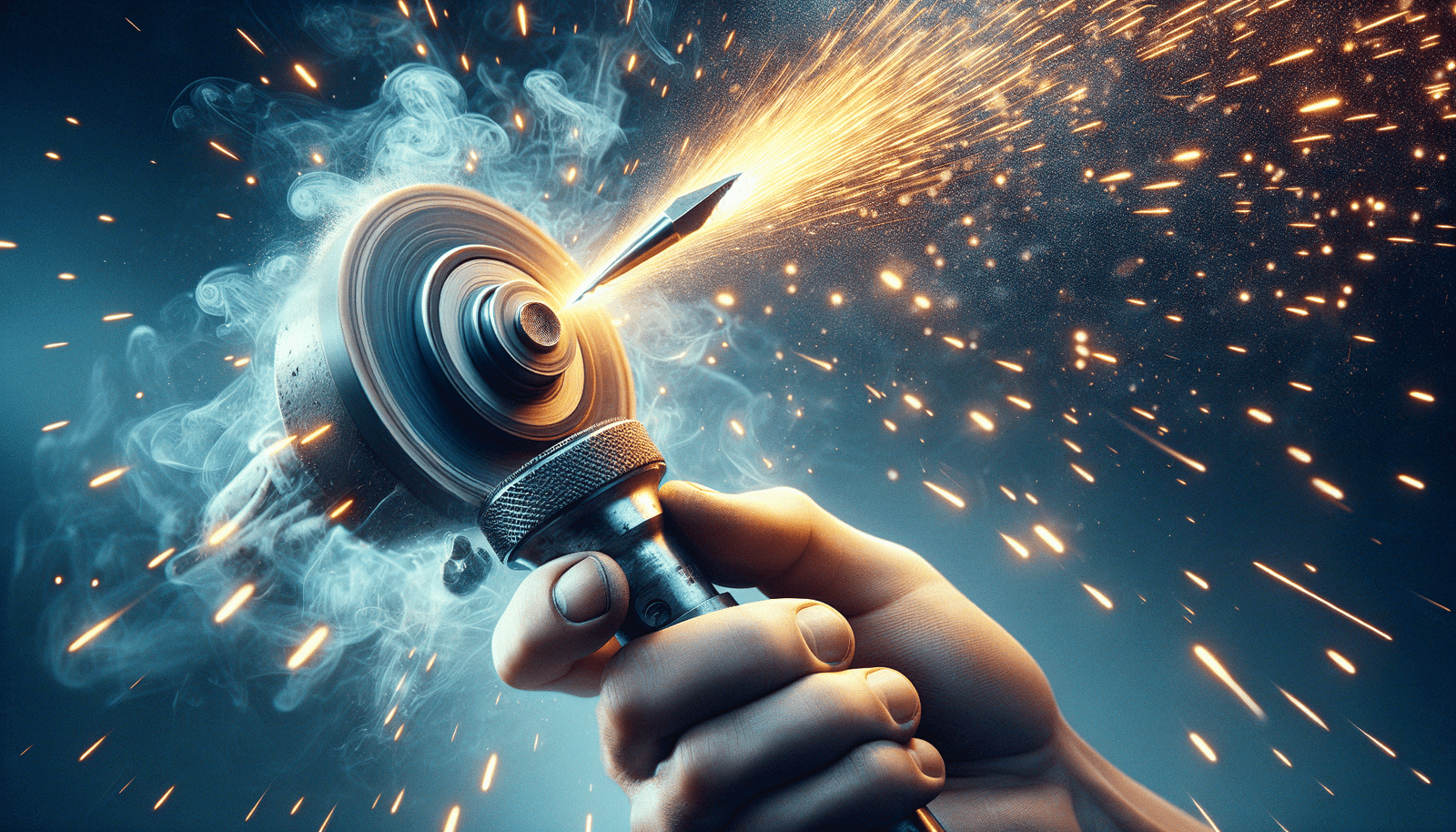

Handheld tungsten sharpeners, as the name suggests, are portable devices that can be easily held and operated by hand. They usually consist of a grinding wheel mounted on a handheld tool that allows for convenient sharpening of tungsten electrodes. Handheld sharpeners are ideal for occasional use or for welders who frequently work on-site or in different locations. They offer flexibility and ease of use, allowing you to sharpen your tungsten electrodes wherever you are. Although handheld sharpeners may not have the same grinding power as their benchtop counterparts, they still provide effective sharpening results for most welding applications.

Choosing the Best Type for Your Needs

When choosing a welding tungsten sharpener, it is important to consider your specific needs and requirements. If you are a professional welder or have a dedicated workshop, a benchtop sharpener may be the best choice for you. The robust construction and powerful grinding capabilities of benchtop sharpeners make them ideal for heavy-duty use. However, if you frequently work on-site or require mobility, a handheld tungsten sharpener may be a better option. They offer portability and convenience without compromising on sharpening quality. Ultimately, the choice between a benchtop and handheld sharpener will depend on your budget, intended use, and personal preference.

Understanding Tungsten Electrodes

Before diving into the specifics of tungsten electrode sharpening, it is essential to have a basic understanding of tungsten electrodes and their importance in welding.

Types of Tungsten Electrodes

Tungsten electrodes come in various types, each with its own unique properties and applications. The most common types of tungsten electrodes are pure tungsten (WP), thoriated tungsten (WT20), and ceriated tungsten (WC20).

- Pure tungsten electrodes are made from 100% tungsten and are primarily used for AC welding applications. They have excellent arc stability but are not suitable for DC welding.

- Thoriated tungsten electrodes contain a small percentage of thorium oxide and are commonly used for DC welding. They have good arc starting characteristics and maintain a sharp point well.

- Ceriated tungsten electrodes, also known as tungsten cerium electrodes, contain cerium oxide and are widely used in both AC and DC welding. They offer excellent arc stability, easy arc initiation, and good current-carrying capacity.

Choosing the correct type of tungsten electrode depends on the welding process, base material, and the type of current being used. It is crucial to consult the welding specifications or seek professional advice when selecting the appropriate tungsten electrode for your welding application.

Importance in Welding

Tungsten electrodes play a significant role in welding, as they serve as the conductive medium to create an electric arc between the electrode and the base material. The arc generated by the tungsten electrode produces the heat necessary to melt the base material and filler metal, resulting in the formation of a weld joint. Proper selection and maintenance of tungsten electrodes are vital to achieve optimal weld quality and performance. A well-sharpened tungsten electrode ensures a stable and focused arc, improving arc control and penetration. It also reduces the risk of tungsten contamination, which can lead to poor weld quality and potential weld defects. By understanding the importance of tungsten electrodes in welding and the role they play in the welding process, you can make informed decisions for your welding projects.

How to Choose the Correct Tungsten Electrode for Sharpening

Choosing the correct tungsten electrode for sharpening involves considering various factors, such as the welding process, base material, and current type. Each type of tungsten electrode has its own unique properties and benefits, making it important to select the appropriate electrode for your specific welding application. Here are some general guidelines to help you choose the correct tungsten electrode for sharpening:

- For AC welding applications, pure tungsten electrodes are generally recommended. They provide excellent arc stability and are suitable for welding aluminum and magnesium.

- For DC welding, thoriated tungsten electrodes are commonly used. They offer good arc starting characteristics and are suitable for a wide range of materials, including mild steel, stainless steel, and non-ferrous metals.

- Ceriated tungsten electrodes are versatile and can be used for both AC and DC welding applications. They provide excellent arc stability, easy arc initiation, and good current-carrying capacity.

It is important to refer to welding specifications, consult welding experts, or seek advice from reputable welding suppliers to determine the correct tungsten electrode for your specific welding needs. By selecting the appropriate tungsten electrode, you can ensure optimal weld quality and performance.

How to Use a Welding Tungsten Sharpener

Using a welding tungsten sharpener may seem daunting at first, but with the right technique and following proper safety measures, it can become a simple and efficient process. Here are the steps to follow while using a sharpener:

Steps to Follow While Using a Sharpener

- Ensure that you have the correct type of tungsten electrode for your welding application.

- Set up the sharpener on a stable surface, ensuring that it is securely held in place.

- Power on the sharpener and adjust the grinding angle according to the recommended angle for your chosen electrode type and welding application.

- Hold the tungsten electrode firmly and place it against the grinding wheel.

- Move the tungsten electrode in a smooth and controlled motion, following the direction of the grinding wheel’s rotation.

- Continue sharpening the electrode until you achieve the desired point shape.

- Inspect the sharpened tungsten electrode for any inconsistencies or defects.

Safety Measures During the Sharpening Process

While sharpening tungsten electrodes, it is essential to prioritize safety to prevent accidents or injuries. Here are a few safety measures to follow:

- Wear safety goggles or a face shield to protect your eyes from sparks and debris.

- Use protective gloves to shield your hands from the grinding wheel.

- Avoid wearing loose clothing or jewelry that could get caught in the spinning wheel.

- Ensure that the sharpening area is well-ventilated to avoid inhaling dust and fumes.

- Keep bystanders at a safe distance to prevent any mishaps.

- Never touch the grinding wheel while it is in motion or immediately after turning off the sharpener.

By observing these safety measures, you can minimize the risk of accidents and safely sharpen your tungsten electrodes.

Avoiding Common Errors in Using Tungsten Sharpeners

When using a tungsten sharpener, there are a few common errors to avoid to ensure optimal sharpening results:

Applying too much pressure: Applying excessive force while sharpening can lead to uneven sharpening or even damage the tungsten electrode. It is important to maintain a steady and controlled pressure on the electrode to achieve a consistent sharpened point.

Incorrect grinding angle: Using the wrong grinding angle can affect the performance and longevity of the tungsten electrode. Consult the recommended angle for your specific electrode type and welding application to ensure the best sharpening results.

Overheating the electrode: Excessive heat buildup can occur when grinding the tungsten electrode for an extended period. This can lead to changes in the properties of the electrode and affect its overall performance. Take breaks between sharpening sessions to allow the tungsten electrode to cool down.

By avoiding these common errors and following the proper sharpening techniques, you can ensure that your tungsten electrodes are sharpened correctly and ready for use in your welding projects.

Maintaining Your Welding Tungsten Sharpener

Proper maintenance of your welding tungsten sharpener is essential to ensure its longevity and consistent performance. Here are some maintenance tips to keep in mind:

Routine Cleaning and Maintenance

Regularly clean your tungsten sharpener to remove any debris or grinding residue that may accumulate over time. Use a soft brush or compressed air to clean the grinding wheel and the surrounding area. This will prevent buildup and ensure optimal sharpening results.

Replacing Worn Out Parts

Check the condition of your tungsten sharpener regularly, paying attention to the grinding wheel. If the wheel is worn out, cracked, or damaged, it is important to replace it with a new one. A worn-out grinding wheel may result in subpar sharpening performance and could potentially damage your tungsten electrodes.

Proper Storage of the Sharpener

When not in use, store your tungsten sharpener in a clean and dry area. Protect it from dust, moisture, and extreme temperatures to prevent any damage. Proper storage will ensure that your sharpener remains in good condition and ready for use whenever you need it.

By following these maintenance practices, you can prolong the lifespan of your welding tungsten sharpener and maintain its functionality.

Sharpening Techniques and Tips

Achieving the perfect point on your tungsten electrode requires some skill and technique. Here are some techniques and tips to help you sharpen your tungsten electrodes effectively:

Choosing the Right Sharpening Angle

The sharpening angle plays a crucial role in the performance of your tungsten electrode. The angle determines the shape of the electrode point and influences the stability and penetration of the welding arc. Consult the recommended sharpening angle for your specific electrode type and welding application. It is important to maintain a consistent angle throughout the sharpening process to ensure a uniform point shape.

Determining the Sharpness of the Electrode

To determine the sharpness of your electrode, visually inspect the sharpened point. It should be clean, smooth, and well-defined. Run your fingers gently over the sharpened point to feel for any irregularities or roughness. A properly sharpened tungsten electrode should have a sharp and polished point, free from any burrs or nicks.

Tips for Achieving the Perfect Point

Here are a few tips to help you achieve the perfect point on your tungsten electrodes:

Use light and consistent pressure while sharpening to avoid excessive heat buildup and maintain control over the grinding process.

Keep a steady hand and maintain a steady motion when moving the electrode against the grinding wheel. This will ensure a uniform and precise point shape.

Take breaks between sharpening sessions to prevent overheating of the tungsten electrode.

Use a fine grit grinding wheel for a smoother and more polished point.

By implementing these techniques and tips, you can sharpen your tungsten electrodes effectively and achieve optimal welding results.

Troubleshooting Common Issues

Even with proper sharpening techniques, you may encounter some common issues while using tungsten sharpeners. Here are a few troubleshooting tips:

Dealing with Overheating Issues

If your tungsten electrode is consistently overheating during the sharpening process, it may indicate that you are applying too much pressure or grinding for an extended period. Allow the electrode to cool down before continuing the sharpening process. Alternatively, you can also switch to a lower grit grinding wheel, as a finer grit tends to generate less heat.

Addressing Sharpening Inconsistencies

If you notice inconsistencies in the sharpened point, such as uneven edges or an irregular shape, it may be due to improper grinding techniques. Ensure that you are maintaining a steady hand and a consistent sharpening angle throughout the process. Take your time and make slow, controlled movements to achieve a uniform point shape.

What to Do When There Are Grinding Marks on Your Tungsten

If you find grinding marks or scratches on your tungsten electrode, it may indicate that you are using an incorrect grinding wheel or applying too much pressure. Switch to a finer grit grinding wheel to minimize the appearance of grinding marks. Additionally, make sure to use smooth and controlled movements to avoid excessive pressure on the electrode.

By troubleshooting and addressing these common issues, you can improve your sharpening technique and achieve better results with your tungsten electrodes.

Understanding the Impact of Sharpening on Weld Quality

The sharpening of tungsten electrodes has a direct impact on the quality of your welds. Here are a few ways in which sharpening affects the overall weld quality:

How Sharpening Affects the Stability of the Arc

A properly sharpened tungsten electrode enhances the stability of the welding arc. A sharp point enables better arc initiation and reduces the likelihood of the arc wandering or extinguishing during the welding process. This stability is crucial for achieving consistent and precise welds.

Role of Sharpening in Reducing Tungsten Contamination

Tungsten contamination in welds can lead to weld defects and poor quality. By regularly sharpening your tungsten electrodes, you remove any potential contaminants, such as oxides or debris, that may accumulate on the surface. This results in cleaner welds with reduced risk of contamination.

Impact of Tungsten Point Shape on Weld Penetration

The shape of the tungsten electrode point can significantly impact weld penetration. A properly sharpened tungsten electrode with a precise point shape allows for better control and focus of the welding arc. This results in improved weld penetration and a more consistent fusion zone.

By understanding the impact of sharpening on weld quality, you can ensure that your tungsten electrodes are in optimal condition and produce high-quality welds consistently.

Safety Measures While Using Welding Tungsten Sharpeners

Safety should always be a top priority when using welding tungsten sharpeners to prevent accidents and injuries. Here are some safety measures to keep in mind:

Proper Gear and Attire

Wear appropriate personal protective equipment (PPE) while using a tungsten sharpener. This includes safety goggles or a face shield to protect your eyes from sparks and debris, protective gloves to shield your hands from the grinding wheel, and a long-sleeved shirt and pants to protect your skin from any potential burns or cuts.

Workshop Safety

Ensure that your workspace is well-ventilated to minimize exposure to dust and fumes. Keep the area clear of any clutter or obstructions that could pose a tripping hazard. Additionally, make sure that the sharpener is securely fastened to a stable surface to prevent any accidental movement or tipping.

Handling the Sharpener Safely to Prevent Injury

Handle the tungsten sharpener with care and ensure that it is turned off and unplugged when not in use. Avoid touching the grinding wheel while it is in motion or immediately after turning off the sharpener. Be mindful of the sharp edges on the sharpened tungsten electrodes and handle them with caution to prevent any cuts or punctures.

By following these safety measures, you can protect yourself and others from potential hazards while using welding tungsten sharpeners.

Proper Disposal of Tungsten Dust

Proper disposal of tungsten dust is important to prevent environmental harm and ensure workplace safety. Tungsten dust, generated during the sharpening process, can contain hazardous substances that should not be released into the environment. Here are some measures to take for its safe disposal:

Hazards of Tungsten Dust

Tungsten dust, if inhaled or ingested, can lead to various health risks, including respiratory issues and possible long-term complications. Additionally, tungsten is classified as a hazardous material by most waste disposal regulations, requiring proper handling and disposal procedures.

Methods of Collecting and Disposing of Tungsten Dust

During the sharpening process, use extraction systems or local exhaust ventilation to collect tungsten dust at the source. These systems capture and filter the dust particles, preventing their release into the air. Collect the extracted tungsten dust in a designated container or bag for proper disposal.

Dispose of the collected tungsten dust according to local regulations and guidelines. Contact your local waste management facility to determine the appropriate method of disposal or recycling. It is important to adhere to these regulations to prevent environmental contamination and potential legal repercussions.

Preventing Environmental Harm through Correct Disposal Methods

Proper disposal of tungsten dust plays a significant role in preventing environmental harm. By collecting and disposing of the dust responsibly, you contribute to maintaining a clean and safe workplace environment.

In conclusion, understanding the importance of welding tungsten sharpeners is crucial for achieving efficient and high-quality welds. The right sharpener allows you to maintain the sharpness of your tungsten electrodes, resulting in improved weld performance and reduced tungsten contamination. By following the proper sharpening techniques, maintenance practices, and safety measures, you can ensure optimal performance of your tungsten sharpener and produce welds of the highest quality. Additionally, proper disposal of tungsten dust is essential for preventing environmental harm and ensuring workplace safety. With the knowledge and skills gained from this article, you are well-equipped to effectively maintain and use welding tungsten sharpeners, leading to successful welding projects and satisfied customers.