Maintaining wind turbines is crucial for their longevity and optimal performance. In this article, we will discuss some common issues that arise during wind turbine maintenance. Whether you are a welding guru or simply looking for welding product reviews, this content aims to provide answers to frequently asked questions. Written in a friendly and approachable tone, this article aims to make the subject easy to understand, avoiding technical jargon whenever possible. Each question will be followed by a concise answer, ensuring that readers can grasp the information without needing to refer to other sections. So, let’s dive in and discover the essential aspects of wind turbine maintenance! And don’t forget, at the end of this article, you’ll find a call to action encouraging you to shop online for all your wind turbine maintenance needs.

Gearbox Failures

Common symptoms of gearbox failures

Gearbox failures in wind turbines can manifest through various symptoms. One of the common indications is unusual noises coming from the gearbox, such as grinding, whining, or clicking sounds. Additionally, if you notice vibration or excessive heat in the gearbox, it could be a sign of a problem. Irregular or erratic operation of the turbine, including improper gear shifting or sudden stops, might also point towards gearbox failures.

Causes of gearbox failures

Several factors can contribute to gearbox failures in wind turbines. One of the primary causes is inadequate lubrication or contaminated lubricant, leading to increased friction and wear on the gears. Misalignment of the gearbox components, such as the pinion and bull gears, can also result in failures. Overloading the turbine beyond its rated capacity, sudden changes in wind speed, or excessive vibrations can put significant stress on the gearbox, potentially leading to failures.

Preventative measures for avoiding gearbox failures

To avoid gearbox failures, regular maintenance and inspection are crucial. Ensure that the gearbox is properly lubricated with clean and appropriate lubricants, following the manufacturer’s recommendations. Periodically checking and adjusting the alignment of the gears can help prevent failures due to misalignment. It is essential to monitor the load on the turbine and avoid exceeding its rated capacity. Additionally, implementing vibration monitoring systems and addressing any abnormalities promptly can help prevent gearbox failures.

Repairing or replacing a faulty gearbox

In the event of a gearbox failure, prompt action is necessary to minimize downtime and prevent further damage to the turbine. Depending on the extent of the damage, the gearbox might need to be repaired or replaced entirely. Engaging a qualified technician or contacting the turbine manufacturer’s service team is recommended for a professional evaluation and appropriate course of action. Properly trained technicians can efficiently diagnose the issue and perform the necessary repairs or facilitate the replacement process, ensuring the turbine is back in operation as soon as possible.

Blade Erosion

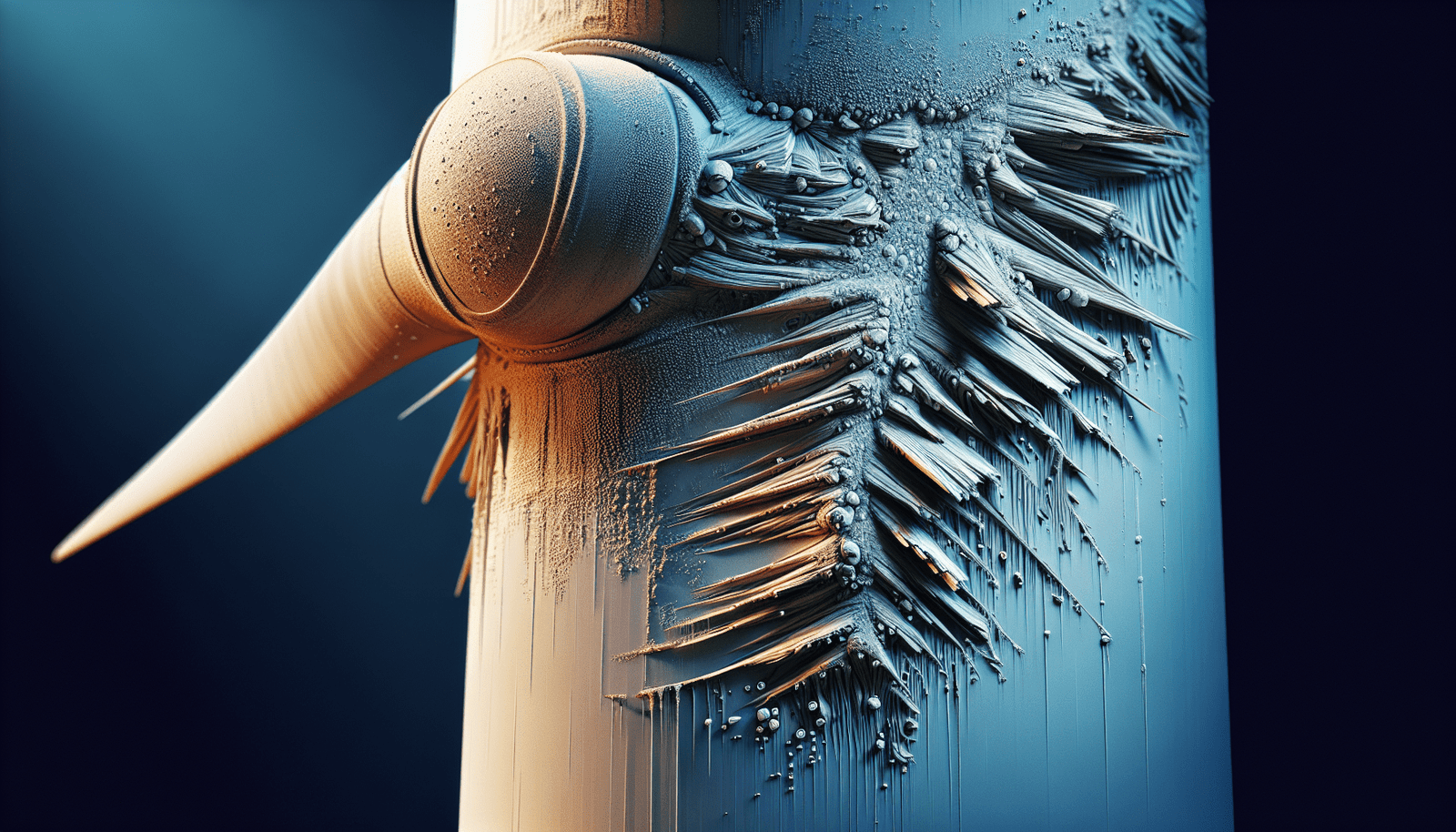

Identifying signs of blade erosion

Blade erosion is a common issue in wind turbine maintenance, and it is essential to identify the signs early to prevent further damage. Visual inspection of the turbine blades can reveal erosion in the form of leading-edge erosion or pitting. Look for rough, worn-out patches or small holes on the blade surfaces. Additionally, if the turbine’s performance noticeably decreases, such as reduced power output or increased noise levels, it could be an indication of blade erosion.

Understanding reasons behind blade erosion

Blade erosion primarily occurs due to environmental factors. The constant exposure to wind, rain, and sand particles can wear down the protective coating on the blades, exposing the underlying material to erosion. Heavy rain containing abrasive pollutants or saltwater spray near coastal areas can accelerate the erosion process. Additionally, the angle of attack of the blades and the speed of the rotating blades can cause erosion on the leading edges.

Preventing early blade erosion

Implementing preventative measures can help extend the lifespan of the turbine blades and prevent early erosion. Applying protective coatings, such as anti-erosion coatings, can significantly reduce the impact of environmental factors on the blades. Regular cleaning and maintenance, including removing debris and dirt from the blades, can help prevent the accumulation of abrasive particles. If the wind turbine is located in a coastal area, considering corrosion-resistant materials or additional protective measures specific to saltwater environments can be beneficial.

Cost-effective repair methods for blade erosion

Once blade erosion has occurred, there are cost-effective repair methods to restore the blades’ integrity and performance. Minor erosions can be repaired through spot repair techniques, where the damaged area is carefully sanded, filled, and coated to match the original blade surface. For more extensive damage, blade section replacement may be necessary. This involves replacing the worn-out blade section with a new one, ensuring the turbine’s optimal performance is restored. Engaging experienced technicians or specialized wind turbine maintenance service providers for these repairs is crucial to ensure the long-term effectiveness of the restoration efforts.

Generator Failures

Typical signs of generator issues

Generator failures in wind turbines can present various signs that indicate a problem. One of the common indications is a decrease in power output from the turbine. If you notice a significant drop in power generation, it could be a sign of a generator problem. Unusual noises, such as knocking or grinding sounds, can also suggest issues with the generator. Additionally, if the generator repeatedly trips or the turbine suddenly stops spinning, it might be experiencing generator failures.

Why a generator might break down

There are several reasons why a generator in a wind turbine might break down. One of the primary causes is electrical faults, such as short circuits or insulation failures, which can lead to overheating and subsequent generator failures. Mechanical issues like bearing failures or misalignment can also cause the generator to break down. Excessive load on the generator, such as operating the turbine beyond its rated capacity, can put significant strain on the components and lead to failures.

Proactive methods to prevent generator problems

To prevent generator problems, regular inspection and maintenance are crucial. Routinely checking the electrical connections, including the wiring and terminals, can help identify any potential faults. Proper lubrication and monitoring of the generator’s bearings can prevent premature failures. Ensuring that the turbine operates within its rated capacity and avoiding sudden load changes can help prolong the generator’s lifespan. Implementing condition monitoring systems, such as vibration analysis and thermal imaging, can provide early indications of potential issues, allowing for proactive maintenance and addressing problems before they escalate.

Ways to fix a failed generator

Fixing a failed generator in a wind turbine requires the expertise of trained technicians. In the event of a generator failure, it is recommended to contact the turbine manufacturer’s service team or engage a reputable wind turbine maintenance service provider. They can perform a thorough assessment to identify the specific cause of the generator failure and recommend the appropriate repair or replacement solution. Depending on the extent of the damage, repairs might involve replacing faulty components, rewinding the generator, or in severe cases, replacing the entire generator assembly. Timely and professional repairs are essential to minimize downtime and ensure the turbine’s optimal performance is restored.

Electrical System Malfunctions

Common indications of electrical system malfunctions

Electrical system malfunctions in wind turbines can exhibit various indications that require attention. One of the common signs is frequent tripping of circuit breakers or fuses within the turbine’s electrical system. If you notice the turbine shutting down abruptly or experiencing intermittent power interruptions, it could be a result of electrical faults. Unusual noises emanating from the electrical components or visible sparks also suggest potential malfunctions within the system.

Root causes of electrical system faults

Electrical system faults can stem from multiple root causes. Insulation failures in the wiring or electrical components, such as transformers or inverters, can lead to short circuits or electrical arcing. Overloading the electrical system by exceeding the turbine’s rated capacity or sudden load changes can cause excessive stress and result in system malfunctions. Faulty or damaged electrical connections, such as loose wiring or corroded terminals, can also contribute to system faults.

Stopping electrical system malfunctions from occurring

Preventing electrical system malfunctions requires diligent maintenance and inspection practices. Regularly checking the electrical wiring and connections for any signs of damage or wear is crucial. Ensuring proper insulation throughout the electrical system, including using appropriate materials and addressing insulation failures promptly, can help prevent electrical faults. Monitoring the load on the turbine and adhering to the rated capacity can prevent overloading and subsequent system malfunctions. Implementing regular testing and diagnostic procedures, such as insulation resistance testing or thermographic inspections, can detect potential issues before they cause significant malfunctions.

Restoring the electrical system

In the event of electrical system malfunctions, it is essential to take prompt action to restore the system’s functionality. Engaging qualified electrical technicians or contacting the turbine manufacturer’s service team is recommended. They can perform a comprehensive evaluation to identify the specific fault within the electrical system. Depending on the nature of the fault, repairs might involve replacing faulty components, rewiring sections, or conducting insulation repairs. Timely repairs and ensuring the system meets the necessary safety standards are vital to prevent further malfunctions and ensure the smooth operation of the wind turbine.

Structural Issues

Detecting structural inadequacies

Detecting structural inadequacies in wind turbines is crucial to prevent potential safety hazards and structural failures. Visual inspections of the turbine’s structure can reveal signs of cracks, deformations, or corrosion on various components, including the tower, support structures, or foundation. Unusual vibrations or excessive noise during turbine operation can also indicate underlying structural issues. Monitoring and documenting any observed structural changes or abnormalities are essential for addressing potential inadequacies promptly.

Causes of structural issues

Structural issues in wind turbines can arise due to several factors. Over time, exposure to environmental factors such as wind, rain, and temperature variations can cause corrosion or degradation of the structural materials. Poor design or manufacturing defects, such as inadequate material selection or insufficient reinforcement, can compromise the structural integrity. Additionally, improper installation or ongoing stress due to wind loads, turbulence, or vibrations can contribute to structural issues.

Preventative tips for maintaining structural integrity

To maintain the structural integrity of wind turbines, proactive measures are necessary. Regular inspections, including visual checks and non-destructive testing methods, can help detect any signs of structural inadequacy early. Implementing corrosion protection measures, such as coatings or sacrificial anodes, can significantly reduce the impact of environmental factors on the turbine’s structure. Periodically reinforcing critical structural components or conducting structural upgrades in accordance with industry standards can enhance the overall strength and longevity of the turbine. Collaboration with experienced structural engineers and adhering to recommended maintenance practices are vital for preventing structural issues.

Repairing any identified structural issues

When structural issues are identified in wind turbines, professional repairs are essential to ensure the safety and continued operation of the turbine. Engaging reputable structural engineering firms or wind turbine maintenance service providers is recommended. They can conduct detailed assessments to determine the extent of the structural issues and develop appropriate repair plans. Repairs might involve welding, reinforced concrete application, or replacement of damaged components, depending on the severity of the structural inadequacies. Strict adherence to industry standards and guidelines is essential to ensure the integrity of the repairs and minimize the risk of future structural failures.

Maintenance Safety Challenges

Understanding safety risks during maintenance

Safety risks during wind turbine maintenance are inherent due to the unique working environment and the presence of potential hazards. Climbing tall turbine towers, working at heights, and dealing with heavy equipment pose significant risks to the maintenance personnel. Factors such as adverse weather conditions, electrical hazards, and the presence of moving parts also contribute to the safety challenges. Awareness and understanding of these risks are crucial for implementing effective safety measures.

Precautions to take during maintenance

To mitigate safety risks during wind turbine maintenance, proper precautions should be taken at all times. Personal protective equipment (PPE), such as helmets, harnesses, gloves, and safety goggles, should be worn by maintenance personnel. Implementing a permit-to-work system, where specific tasks require authorization and coordination, ensures efficient communication and minimizes accidents. Adhering to established lockout/tagout procedures when working with electrical systems or machinery prevents unexpected releases of energy. Regular training on safe work practices, emergency procedures, and working at heights is essential to enhance the safety awareness of the maintenance team.

Creating a safe work environment

Maintaining a safe work environment is crucial for the overall safety of wind turbine maintenance operations. Implementing comprehensive safety policies and protocols, including risk assessments and safety audits, ensures that safety measures are consistently followed. Regular equipment inspections and maintenance, such as checking the condition of safety harnesses or inspecting the integrity of scaffolding, help identify any potential hazards. Clear signage, safety barriers, and proper lighting contribute to a safer work environment. Promoting a strong safety culture through training, communication, and recognition of safe behaviors fosters a proactive approach to safety among the maintenance team.

Dealing with safety-related incidents

Despite precautionary measures, safety incidents can still occur during wind turbine maintenance. It is crucial to have well-defined emergency response procedures in place to handle such situations effectively. Establishing communication protocols and emergency contact information ensures prompt response to any safety incidents. Conducting thorough investigations and analyses of incidents allows for identifying the root causes and implementing corrective actions to prevent future occurrences. Regular safety training refreshers and open channels for reporting near-misses or safety concerns foster continuous improvement in safety performance.

Turbine Accessibility

Navigating accessibility issues for wind turbines

Wind turbines’ accessibility can pose challenges for maintenance and inspection tasks, particularly for offshore installations or turbines located in remote areas. Limited access due to tall towers, narrow entrances, or difficult terrain can make it challenging to reach the turbine’s components. Coordination and planning are crucial to ensure accessibility during maintenance operations, considering factors such as weather conditions, transportation logistics, and availability of specialized equipment.

Planning regular maintenance given accessibility constraints

Effective planning is key to address accessibility constraints for regular maintenance of wind turbines. Developing detailed maintenance schedules, considering the availability of resources, accessibility constraints, and downtime implications, helps optimize the maintenance operations. This involves carefully planning and sequencing tasks based on the priority and accessibility of the turbine’s components. Coordination with logistics teams and service providers ensures the timely delivery of personnel, equipment, and materials required for maintenance activities, despite the accessibility challenges.

Innovative solutions for turbine accessibility

Innovative solutions can be employed to overcome accessibility challenges in wind turbine maintenance. Developing specialized access systems, such as advanced climbing equipment, personal lifts, or robotic systems, can enhance the efficiency and safety of operations in challenging environments. Implementing remote monitoring technologies and drones equipped with cameras or sensors can provide real-time visual inspection data, reducing the need for physical access to certain areas. Collaboration with experienced wind turbine maintenance service providers and employing their expertise in navigating accessibility issues can help implement innovative solutions tailored to specific turbine locations.

Impact of location on turbine maintenance

The location of wind turbines significantly impacts the maintenance operations. Offshore wind farms require additional planning and logistics to account for the challenging conditions and limited accessibility. Harsh weather conditions, such as high winds or icing, can restrict maintenance activities and require specialized equipment or personnel trained in offshore operations. Turbines located in remote areas might require longer travel times and considerations for the availability of local resources. Properly assessing the location-specific factors and tailoring maintenance plans accordingly ensures effective and efficient turbine maintenance operations.

Preventative Maintenance Schedules

Importance of regular preventative maintenance

Regular preventative maintenance is vital for ensuring the optimal performance and longevity of wind turbines. It helps identify and address potential issues before they escalate, minimizing unplanned downtime and costly repairs. Preventative maintenance can extend the lifespan of critical components, increase energy production efficiency, and ensure compliance with industry standards and regulations. By detecting and correcting minor problems early, regular maintenance reduces the risk of major failures and enhances the safety of wind turbine operations.

Creating a maintenance schedule for wind turbines

Creating a comprehensive maintenance schedule for wind turbines requires a systematic approach. It involves identifying the specific maintenance tasks and intervals based on the manufacturer’s recommendations, industry best practices, and environmental factors. Regular inspections, lubrication of components, and cleaning procedures can be scheduled at set intervals. Monitoring systems, such as vibration analysis and oil analysis, might require periodic checks to ensure early detection of potential issues. Collaborating with turbine manufacturers, maintenance service providers, and experienced technicians can help develop an effective maintenance schedule tailored to the specific turbine model and operating conditions.

Adapting maintenance schedules based on turbine age, condition

As wind turbines age, their maintenance requirements and frequencies may need adjustments. Components experience wear and tear over time, necessitating more frequent inspections and replacements. Assessing the condition of critical components, such as the blades, gearbox, or generator, becomes crucial to determine the appropriate maintenance intervals. Factors such as the operating hours, operating conditions, and historical performance data can influence the maintenance schedules. Regular performance monitoring and trend analysis enable continuous evaluation of the turbine’s condition, allowing for timely adjustments to the maintenance schedules to ensure optimal performance and reliability.

Monitoring and adjusting a preventative maintenance schedule

Continuous monitoring and evaluation of the wind turbine’s performance and condition are essential for maintaining an effective preventative maintenance schedule. Real-time data collection and analysis, including performance monitoring systems, condition monitoring systems, and asset management tools, empower maintenance teams to make informed decisions. Analyzing trend data, identifying patterns, and performance deviations can trigger adjustments to the maintenance schedules. Regular review of the maintenance records, feedback from technicians, and collaboration with turbine manufacturers or maintenance service providers contribute to the ongoing improvement and optimization of the preventative maintenance schedule.

Weather-related Maintenance Issues

Impact of weather conditions on wind turbines

Weather conditions have a significant impact on wind turbines and can pose maintenance challenges. High winds, storms, and lightning can cause damage to the turbine blades, structure, or electrical system. Freezing temperatures can lead to ice buildup on the blades, affecting aerodynamic performance and potentially causing imbalance. Extreme heat or humidity can accelerate deterioration of materials and increase the risk of electrical faults. Understanding the potential weather-related risks to wind turbines is crucial for planning maintenance activities and implementing appropriate countermeasures.

Addressing maintenance needs after severe weather

After severe weather events, wind turbines require thorough inspections and maintenance to address any potential damage. Visual inspection of the turbine components, including the blades, tower, and electrical systems, is necessary to detect any signs of wear, corrosion, or physical damage caused by the weather conditions. Repair or replacement of damaged components might be necessary. It is important to engage qualified technicians or service providers to conduct in-depth assessments and develop comprehensive repair plans. Timely and effective maintenance after severe weather events ensures the safe and reliable operation of wind turbines.

Weather-proofing methods for wind turbine longevity

Weather-proofing wind turbines is essential to enhance their longevity and minimize weather-related maintenance issues. Applying protective coatings to the turbine blades and structure can provide resistance against environmental factors, such as corrosion or erosion. Implementing lightning protection systems, including surge arresters and grounding systems, helps mitigate the risks associated with lightning strikes. For turbines located in cold climates, installing ice prevention systems, such as blade heating or ice detectors, can prevent ice buildup and potential damage. Regular monitoring and cleaning procedures also contribute to maintaining the turbine’s resilience against weather-related challenges.

The role of climate in turbine maintenance

The climate in which wind turbines operate plays a crucial role in their maintenance requirements. Turbines located in coastal areas might experience increased exposure to saltwater spray or corrosive pollutants, requiring additional corrosion protection measures. Wind turbines in hot and dry climates might suffer from increased dust accumulation, necessitating more frequent cleaning procedures. Turbines in cold climates face the risks of ice buildup and freezing temperatures, emphasizing the importance of implementing ice prevention systems and conducting regular inspections. Adapting maintenance plans and practices based on the specific climate conditions ensures the longevity and optimal performance of wind turbines.

Personnel Training and Skill Requirements

Understanding the need for skilled technicians in wind turbine maintenance

Skilled technicians are indispensable in wind turbine maintenance to ensure the efficient and safe operation of the turbines. Their expertise is essential in conducting inspections, diagnosing issues, and performing repairs or replacements. Skilled technicians possess the knowledge and practical skills to work with complex mechanical, electrical, and structural systems found in wind turbines. Their ability to adapt to challenging working environments and adhere to safety standards is crucial for maintaining the integrity and reliability of the turbines.

Required training and qualifications for maintenance staff

Maintenance staff in wind turbine operations require specific training and qualifications to perform their roles effectively. Formal education or technical training in relevant fields, such as electrical engineering, mechanical engineering, or renewable energy, provides the foundation for understanding wind turbine systems. Additionally, specialized training programs, such as turbine-specific certifications, safety training, or working at heights training, are essential for developing the necessary skills. Familiarity with industry standards and regulations, as well as experience working in wind turbine maintenance, further enhances the qualifications of maintenance staff.

Continuing education and skill development for technicians

Continuing education and skill development are crucial for technicians to keep up with advancements in wind turbine technology and industry best practices. Technicians should actively participate in relevant workshops, conferences, and training programs to stay updated on the latest maintenance techniques and technologies. Ongoing professional development allows technicians to expand their knowledge, exchange experiences with peers, and adapt to the evolving needs of the wind turbine industry. Investing in the continuous improvement of technicians’ skills ultimately benefits the maintenance operations and enhances the overall performance of wind turbines.

Impact of insufficient personnel training on turbine performance

Insufficient personnel training in wind turbine maintenance can have significant consequences on the performance and reliability of the turbines. Inadequate training might lead to misdiagnosis of issues, improper repairs, or safety hazards. A lack of understanding of the intricate systems within the wind turbine can result in missed opportunities for preventative maintenance or early detection of potential failures. Insufficient knowledge of safety protocols, procedures, and emergency response measures increases the risk of accidents or injuries during maintenance activities. Investing in comprehensive and ongoing training for maintenance personnel is essential to optimize turbine performance and ensure safe maintenance operations.

With a comprehensive understanding of these key wind turbine maintenance issues and proactive measures in place, you can ensure the optimal performance, reliability, and safety of your wind turbines. Regular maintenance, thorough inspections, and adherence to industry best practices will help prevent major failures, minimize downtime, and maximize the lifespan of your wind turbine assets. Engaging experienced technicians and collaborating with reputable wind turbine maintenance service providers are crucial for successful maintenance operations. By prioritizing maintenance and addressing issues promptly, you can secure the long-term viability and efficiency of your wind energy generation.