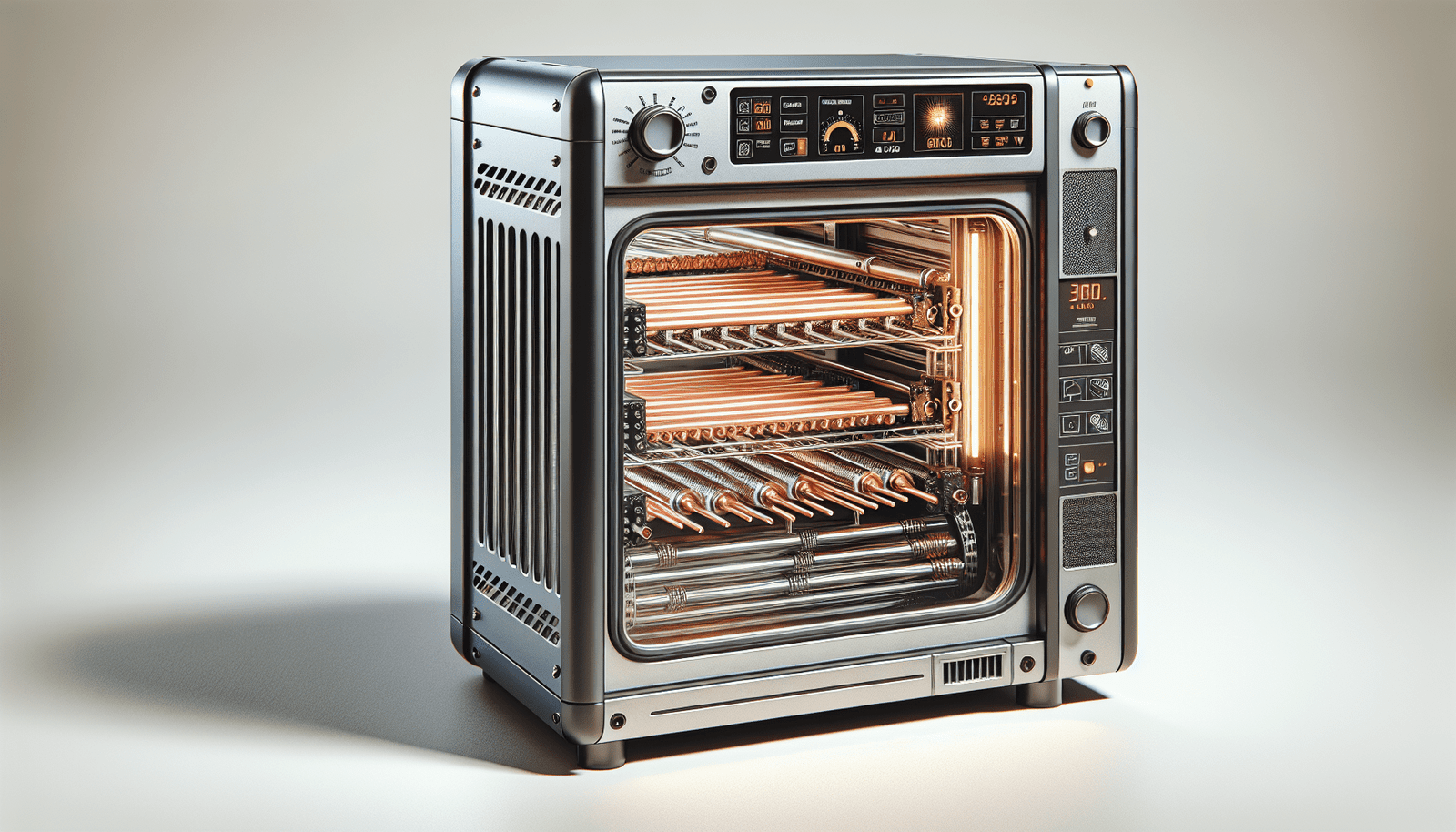

When it comes to welding, proper rod storage is essential for ensuring optimal performance. That’s where welding rod ovens come into play. These ingenious devices are designed to keep your welding rods dry and at the optimal temperature, allowing you to get the most out of your welding projects. But with so many options out there, how do you know which welding rod oven is right for you? In this article, we will explore the key features to consider when choosing a welding rod oven, helping you make an informed decision and keep your welding rods in top-notch condition. So, let’s dive in and discover how to enhance your welding experience with the right welding rod oven.

Welding Rod Ovens – Things to Consider for Storage

Understanding the Importance of Welding Rod Storage

When it comes to welding, one of the most vital aspects is the storage of welding rods. Proper storage is crucial for preserving the integrity of the welding rod, preventing electrode contamination, and extending the lifespan of the rods.

Preserving the integrity of the welding rod

Welding rods are sensitive to external factors such as moisture, humidity, and extreme temperatures. To maintain their integrity, it is vital to store them in an environment that protects them from these elements. Welding rod ovens play a significant role in preserving the quality of the rods by providing a controlled and stable storage environment.

Preventing electrode contamination

Contamination of welding electrodes can lead to poor weld quality and compromised safety. Exposure to dirt, dust, and moisture can contaminate the surface of the electrodes, affecting their performance. Proper storage in rod ovens minimizes the risk of contamination, ensuring that the welding rods remain clean and ready for use.

Extending lifespan of welding rods

Welding rods are an investment, and their lifespan directly impacts the overall cost of welding projects. By storing welding rods in rod ovens, you can extend their lifespan significantly. The controlled environment prevents corrosion, rust, and other forms of degradation, allowing the rods to maintain their performance for a longer time.

The Role of Welding Rod Ovens

Welding rod ovens play a crucial role in maintaining the optimum performance of electrodes, preventing moisture accumulation, and ensuring uniform temperature distribution.

Maintaining optimum electrode performance

Welding electrodes perform best within a specific temperature range. When stored in rod ovens, the electrodes are exposed to a controlled temperature that suits their specific requirements. This ensures that the electrodes remain in optimal condition, ready to provide high-quality welds whenever needed.

Preventing moisture accumulation

Moisture is a common adversary in welding rod storage. When exposed to moisture, the electrodes can become damp, contributing to poor weld quality and potentially causing defects. Welding rod ovens control the humidity levels, preventing moisture accumulation and keeping the welding rods dry and moisture-free.

Ensuring uniform temperature distribution

Temperature distribution is crucial to maintaining the quality and performance of welding rods. Uneven temperatures can lead to thermal stress, which can affect the integrity of the rods. Rod ovens ensure uniform temperature distribution throughout the storage area, preventing any hot or cold spots that may compromise the quality of the rods.

Key Feature: Temperature Control

Temperature control is a critical feature to consider when choosing a welding rod oven. It ensures that the storage environment provides the optimal temperature for the welding rods.

Importance of precision temperature control

Welding rods have specific temperature requirements for storage. Precision temperature control allows you to set and maintain the exact temperature needed for the rods. This precision ensures that the rods are stored in the optimal conditions and are always ready for use.

Adjustable thermostat feature

An adjustable thermostat is an essential feature in a welding rod oven. It allows you to tailor the temperature settings to the specific requirements of different types of welding rods. This versatility ensures that you can store a variety of rods without compromising their performance.

Digital vs. analog temperature display

The type of temperature display can vary between digital and analog. Digital displays provide precise temperature readings, allowing for easier monitoring and temperature adjustment. Analog displays, on the other hand, offer simplicity and durability. Choosing between digital and analog depends on personal preference and requirements.

Key Feature: Capacity

Capacity is an important consideration when selecting a welding rod oven. It determines how many rods you can store, and choosing the right capacity ensures efficient storage and easy access.

Understanding rod capacity

Rod capacity refers to the maximum number of welding rods that can be stored in an oven. Capacities can vary depending on the size and design of the oven. It is crucial to consider the capacity that aligns with your welding needs and the number of rods you typically use.

Choosing the right capacity based on usage

Selecting the right capacity is essential to avoid overloading the oven or underutilizing its storage potential. Assess your welding requirements and the number of rods you typically go through to determine the ideal capacity for your rod oven.

Impact of overloading on performance

Overloading a rod oven can negatively impact its performance. When an oven is packed beyond its capacity, it may struggle to maintain the desired temperature and distribute it evenly. This can result in compromised storage conditions, affecting the quality and lifespan of the welding rods.

Key Feature: Temperature Range

The temperature range of a welding rod oven determines its suitability for different types of rods. Understanding the appropriate temperature range is crucial for effective rod storage.

Understanding the appropriate temperature range

Different types of welding rods have specific temperature requirements for storage. It is essential to choose a rod oven with a temperature range that accommodates the rods you commonly use. This ensures that the rods are stored at their optimal temperature, preserving their quality.

Impact of temperature range on different types of rods

Failure to store welding rods within their appropriate temperature range can result in decreased performance and compromised weld quality. High-temperature storage can lead to degradation and brittleness, while low-temperature storage can affect moisture levels and electrode performance. Selecting an oven with the right temperature range is vital for maintaining the quality of your welding rods.

Features for the efficient temperature range

Certain rod ovens come with features that enhance temperature efficiency. These features can include insulation, adjustable temperature settings, and temperature monitoring systems. These enhancements ensure that the oven maintains a stable and accurate temperature range, providing the ideal storage conditions for your welding rods.

Key Feature: Insulation

Insulation is a critical feature in welding rod ovens. It plays a vital role in maintaining a consistent temperature, preventing energy loss, and protecting the rods.

Importance of proper insulation

Proper insulation is crucial for preventing temperature fluctuations caused by external factors. It helps to maintain a steady temperature within the oven, regardless of the ambient conditions. This insulation ensures that the welding rods are consistently stored in the desired temperature range.

Types of insulation materials used in rod ovens

Welding rod ovens use various insulation materials to provide optimal thermal insulation. Common materials include ceramic fiber insulation, fiberglass insulation, and mineral wool insulation. Each has its own thermal properties, durability, and insulation efficiency, so choosing the right material depends on your specific requirements.

Insulation efficiency and energy saving

Efficient insulation not only maintains temperature consistency but also contributes to energy savings. Insulated rod ovens require less energy to maintain the desired temperature, reducing energy costs and making them more environmentally friendly.

Key Feature: Portability

Portability is an important consideration for welders who work in different locations or environments. Portable rod ovens offer convenience and flexibility, but they also come with their pros and cons.

Pros and Cons of portable rod ovens

Portable rod ovens allow for easy transportation to different job sites or welding areas. They are lightweight and compact, making them highly convenient. However, portable ovens may have limited storage capacity compared to larger, stationary models. Additionally, they may require separate power sources, such as batteries or generators, depending on the location.

Importance of portability in different welding environments

Portability is particularly important for welders who work in remote or challenging locations. It ensures that the welding rods can be stored properly, regardless of the site conditions. Whether it’s on construction sites, oil rigs, or shipyards, portable rod ovens provide the necessary storage solution for welders on the go.

Features that enhance portability

Certain features enhance the portability of welding rod ovens. These can include carrying handles, compact designs, and compatibility with various power sources. Consider these features when selecting a portable rod oven to ensure ease of transportation and convenience in different welding environments.

Key Feature: Durability and Construction

Durability and construction are important factors in choosing a welding rod oven. The materials used and the overall design can directly impact the lifespan and usability of the oven.

Materials used in oven construction

Rod ovens are commonly constructed using materials such as stainless steel, aluminum, or rugged plastics. These materials offer durability, resistance to corrosion, and ease of cleaning. Stainless steel is particularly popular due to its strength and ability to withstand high temperatures.

Impact of construction on the lifespan of the oven

The construction quality of a rod oven can determine its lifespan and performance. A well-built oven with sturdy materials and excellent craftsmanship will have a longer lifespan, ensuring that it serves you well for years to come. On the other hand, a poorly constructed oven may be prone to wear, corrosion, and other malfunctions, leading to a shorter lifespan and potential safety hazards.

Usability and design considerations

The design of a welding rod oven can greatly impact its usability and convenience. Look for features such as easy-access doors, organized storage racks, and user-friendly controls. A well-designed oven makes it easier to retrieve and store welding rods, contributing to efficient workflow and minimizing the risk of damage.

Specialized Welding Rod Ovens

For certain industries or specialized welding applications, standard rod ovens may not suffice. Specialized welding rod ovens offer features tailored to specific requirements.

Understanding industrial welding rod ovens

Industrial welding rod ovens are designed to meet the high demands of industrial settings. They often have larger capacities, enhanced temperature controls, and durable construction. These ovens are suitable for heavy-duty welding projects and organizations with high welding rod consumption.

Features specific to specialized welding rod ovens

Specialized rod ovens may have additional features that cater to specific industries or applications. For example, some may include humidity control mechanisms for welding in humid environments, or they may have explosion-proof certifications for hazardous locations. These specialized features ensure that the rod oven meets the unique needs of the industry or application.

When to opt for specialized welding rod ovens

Opting for a specialized rod oven depends on the specific requirements of your welding projects or industry. If you’re working in a high-volume environment with unique demands, such as offshore welding or nuclear applications, a specialized oven may be necessary to ensure optimal rod storage and performance. Assess your needs and consult industry experts to determine if a specialized rod oven is the right choice for you.

Maintenance of Welding Rod Ovens

Proper maintenance of welding rod ovens is crucial for their optimal performance and longevity. Regular maintenance routines, peripherals, and accessories are essential for effective and safe operation.

Routine maintenance for enhanced performance

Regular maintenance is key to keeping your rod oven in excellent working condition. This includes cleaning the interior and exterior surfaces, checking and replacing faulty components, and ensuring proper insulation. Adhering to a routine maintenance schedule will help prevent breakdowns, maximize oven lifespan, and ensure the quality storage of your welding rods.

Peripherals and accessories for maintenance

Peripherals and accessories can aid in the maintenance of your rod oven. These can include temperature monitors, cleaning kits, spare parts, and insulation blankets. Depending on the type of oven you have, these accessories can contribute to efficient operation and simplify maintenance tasks.

Tips for effective and safe maintenance

When performing maintenance on your rod oven, it’s essential to follow safety guidelines. Ensure that the oven is disconnected from the power source and cooled down before proceeding. Use appropriate cleaning agents and tools for the interior and exterior surfaces, and always refer to the manufacturer’s instructions for specific maintenance procedures. Regularly inspect the oven for any signs of wear, damage, or malfunction, and address any issues promptly to maintain a safe and reliable storage environment for your welding rods.

In conclusion, understanding the importance of welding rod storage and the key features of welding rod ovens is crucial for welders. Proper storage preserves the integrity of the welding rods, prevents contamination, and extends their lifespan. Welding rod ovens play a vital role in maintaining optimum electrode performance, preventing moisture accumulation, and ensuring uniform temperature distribution. Features such as temperature control, capacity, temperature range, insulation, portability, durability, and construction all contribute to the functionality and effectiveness of rod ovens. By considering these factors and performing regular maintenance, welders can ensure that their welding rods are stored properly, leading to enhanced weld quality and overall efficiency in their welding projects.